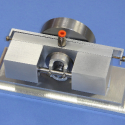

.040 Opposed 2-Cylinder, 2-Cycle Aero Engine

Craftsman: John Swartzwelder

Knapp Collection #: 206

Catalog #: 2008.16.49

Contributor: Paul Knapp

John Swartzwelder fabricated several small multi-cylinder aircraft engines from commercially available Cox .049, .020, and .010 cc model airplane engines.

.098 Opposed 2-Cylinder, 2-Cycle Aero Engine

Craftsman: John Swartzwelder

Knapp Collection #: 205

Catalog #: 2008.16.47

Contributor: Paul Knapp

John Swartzwelder fabricated several small multi-cylinder aircraft engines from commercially available Cox .049, .020, and .010 cc model airplane engines.

.098 Vertical 2-Cylinder, 2-Cycle Aero Engine

Craftsman: John Swartzwelder

Knapp Collection #: 204

Catalog #: 2008.16.46

Contributor: Paul Knapp

John Swartzwelder fabricated several small multi-cylinder aircraft engines from commercially available Cox .049, .020, and .010 cc model airplane engines.

’32 Ford Coupe Tether Car

Craftsman: Marshall Ziegert

Catalog #: 2016.8.14

Contributor: 419

This ’32 Ford tether car measures about 7 inches wide, 4.25 inches high, 13 inches long, and weighs 6.25 pounds.

“Dominator” Model Aircraft Engine

Craftsman: Noel Jensen

Knapp Collection #: 85

Catalog #: 2008.10.26

Contributor: Paul Knapp

To achieve more power, Noel Jensen added two more cylinders and produced this flat 4-cylinder opposed engine dubbed the “Dominator.”

“Green Dragon” Model Airplane Engine

Craftsman: John Nuovo

Knapp Collection #: 132

Catalog #: 2008.10.37

Contributor: Paul Knapp

The Green Dragon burns methanol with castor oil mixed in for lubrication on spark ignition. The engine is 7″-long, 5″-wide, and 6″-high.

“Green Dragon” Model Automobile Engine

Craftsman: John Nuovo

Knapp Collection #: 133

Catalog #: 2008.10.38

Contributor: Paul Knapp

This two-cycle, air-cooled Green Dragon automobile engine was named for its green crackle paint finish. This engine is 7″-long, 5″-wide, and 6″-high.

“KEN” Single-Cylinder, Air-Cooled Marine Engine

Craftsman: Dick Pretel

Knapp Collection #: 181

Catalog #: 2008.16.32

Contributor: Paul Knapp

From approximately six sets of castings made by Ken Brennerman in the mid 1930s, this is the only known surviving engine.

“Little Dominator” Model Aircraft Engine

Craftsman: Noel Jensen

Knapp Collection #: 84

Catalog #: 2008.10.25

Contributor: Paul Knapp

A rotary valve, twin-cylinder, air-cooled engine named “Little Dominator.” The 1″-bore and 1.1″-stroke engine turns a 16/6 propeller at 6,000 rpm.

“Maxse T-Seven” 7-Cylinder Radial Model Airplane Engine

Craftsman: Maxse Tayler

Knapp Collection #: 126

Catalog #: 2008.10.36

Contributor: Paul Knapp

Maxse Tayler used the piston and cylinder assemblies from the commercially manufactured Saito 120 model airplane engines to build this 7-cylinder radial.

“Micro Cirrus” V8 Engine

Craftsman: Profi M. E.

Knapp Collection #: 112

Catalog #: 2008.10.31

Contributor: Paul Knapp

This 1/12 scale “Micro Cirrus” engine runs on methanol with glow ignition, and is among the smallest multi-cylinder 4-cycle engines in the world.

“Rasant MK III” Diesel Radial Model Airplane Engine

Craftsman: Ron Valentine

Knapp Collection #: 135

Catalog #: 2008.10.39

Contributor: Paul Knapp

This “Rasant MKIII” Diesel engine operates like an inline engine. It is 2.5″-long, 3″-wide, and 2″-high.

“Root Special” DOHC 4-Cylinder Racing Engine

Craftsman: Lee Root

Knapp Collection #: 104

Catalog #: 2009.9.17

Contributor: Paul Knapp

The “Root Special” is machined entirely from 7075 aluminum bar stock and utilizes no castings. The aluminum parts were clear anodized to produce the color and finish.

“Sea Lion” 4-Cylinder Water-Cooled Marine Engine

Craftsman: Jim Hawk

Knapp Collection #: 124

Catalog #: 2008.10.35

Contributor: Paul Knapp

This tiny marine engine was designed and sold as a casting kit. Jim Hawk made several modifications to the original design to improve efficiency and performance.

“So What Speed Shop” OS Powered Tether Car

Craftsman: Chris Garcia

Knapp Collection #: 421

Catalog #: 2016.8.16

Contributor: Paul Knapp

This aluminum tether car was custom-built by Chris Garcia for Ed Hegarty and sports Chris’s custom wire wheels.

“Double Scotch” Scotch Yoke Steam Engine

Craftsman: Roger Butzen

Knapp Collection #: 763

Catalog #: 2024.5.9

Contributor: Paul Knapp

This “Double Scotch,” Scotch Yoke steam engine was built in the mid-1990s by Roger Butzen.

“Eldon I 2636” 6-Cylinder Inline Model Boat Engine

Craftsman: Jim Hawk

Knapp Collection #: 189

Catalog #: 2008.10.52

Contributor: Paul Knapp

This engine is water-cooled (including the exhaust), sports a 120-degree crankshaft, and burns methanol on glow ignition. It measures 13″- long, 7″-wide, and 7″-high.

“Gannet” Single-Cylinder, Water-Cooled Marine Engine

Craftsman: Gannet Engines; Modified by Dick Pretel

Knapp Collection #: 180

Catalog #: 2008.16.31

Contributor: Paul Knapp

Dick Pretel modified the popular Gannet marine engine to suit his performance demands. His newly designed head included four valves and an extra exhaust pipe for better breathing.

“Iron Maiden” Steam Traction Engine

Craftsman: Stephen J. King

Knapp Collection #: 242

Catalog #: 2011.27.23

Contributor: Paul Knapp

The “Iron Maiden” steam traction engine is a reversible double acting engine with a .4-inch bore, 1.25-inch stroke, and a 25:1 drive ratio with a clutch.

Showing 20 of 391 exhibits.