A Craftsman Who Builds and Collects Engines—Over 300 and Counting!

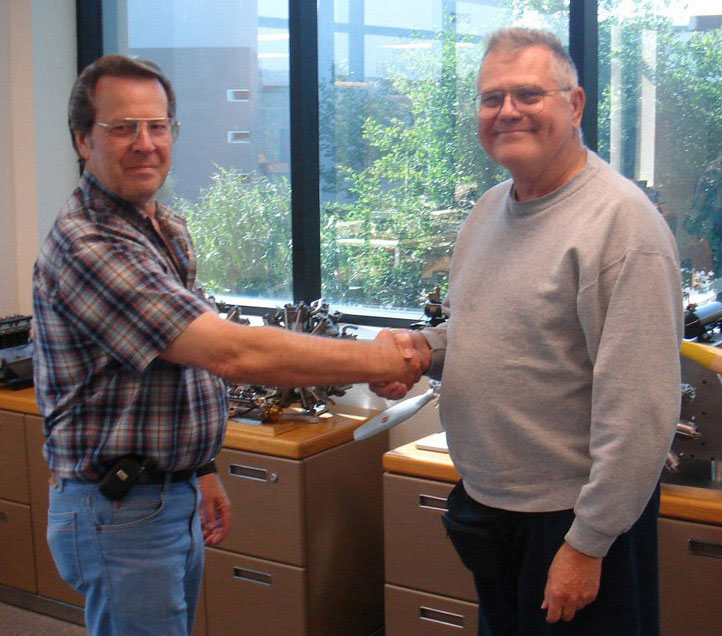

Paul Knapp (left) shakes hands with Joe Martin after loaning the majority of his large engine collection for display at the Miniature Engineering Craftsmanship Museum in Carlsbad, CA. Since then, Paul has loaned more than 200 other engines to the museum. Paul also agreed to serve on the Board of Directors for The Joe Martin Foundation starting in 2009.

A Craftsman and His Tools

By Joe Martin

We all know that good craftsmen work with the tools they have available. Now ask yourself, “If a craftsman has more or better tools, does that make them any less of a craftsman?” Personally, I think not, because each additional tool requires additional skills to make it useful.

Take Paul Knapp for example. Here’s a man who owns a modern machine shop and then gets interested in model engines. His skills and experience will make him approach building an engine in an entirely different manner than an old time toolmaker who can build anything on a Bridgeport and a lathe.

Paul has CNC equipment and knows that once tooling is built and a program is written, it’s relatively easy to duplicate parts; therefore, he’d be inclined to build multi-cylinder engines. In the back of his mind he’d also be considering the engine as a possible product and would document what he’s doing better than the toolmaker.

It’s time to ask yourself again about the relationship between a craftsman and his tools. Perhaps it’s a tie. Both of these craftsmen have a great deal of skill and deserve our admiration. They just go about creating their marvelous work with different tools and different goals. As a spectator in the world of superb craftsmanship, I’m happy with end results in either case. When I examine Paul’s finished engine and then watch Paul fire up the same engine, I know that he is taking his hobby to a new level—and we’ll all be better because of it.

—Joe Martin

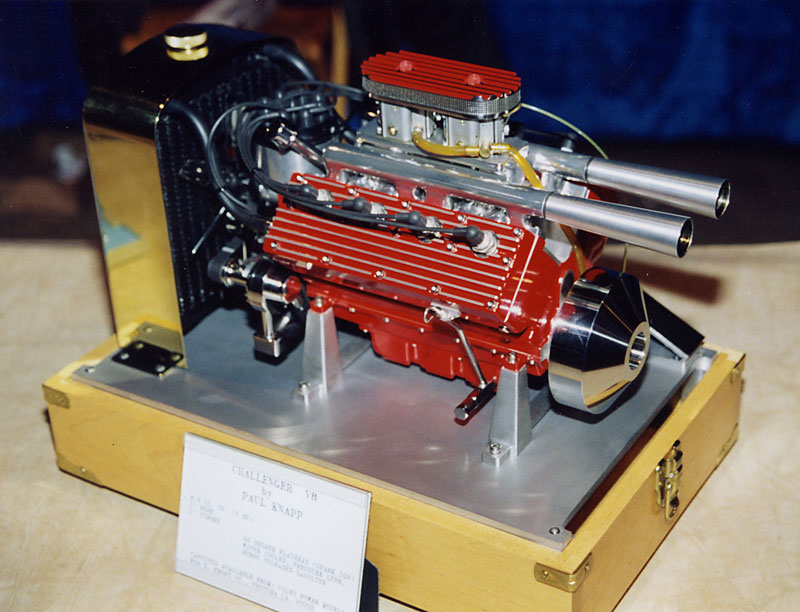

Paul Knapp built this Challenger V-8 engine from a Coles Power Models casting set. The heavy flywheel allows him to start it by hand once the engine is warmed up. It takes a fairly well-tuned engine to start that easily.

About Paul Knapp

To start, Paul Knapp is a fine craftsman himself, with a real passion for internal combustion engines. Not only has this passion driven Paul to build his own engines, but he has also acquired a massive collection of some of the finest engines from all over the world. Mr. Knapp’s wife, Paula, is also very knowledgeable about the individual engines in the collection. Paula has always been very supportive of Paul’s desire to acquire and display his truly impressive collection of the best engines from across the globe.

Over the past few decades, the Knapp’s have put together a collection of over 300 of the finest, most significant model engines to be found. As part of Paul’s Miniature Engineering Museum, the engines have been on display at airports and museums around the western US. Fortunately for us, Paul decided to display the majority of his collection at the Miniature Engineering Craftsmanship Museum in Carlsbad, CA.

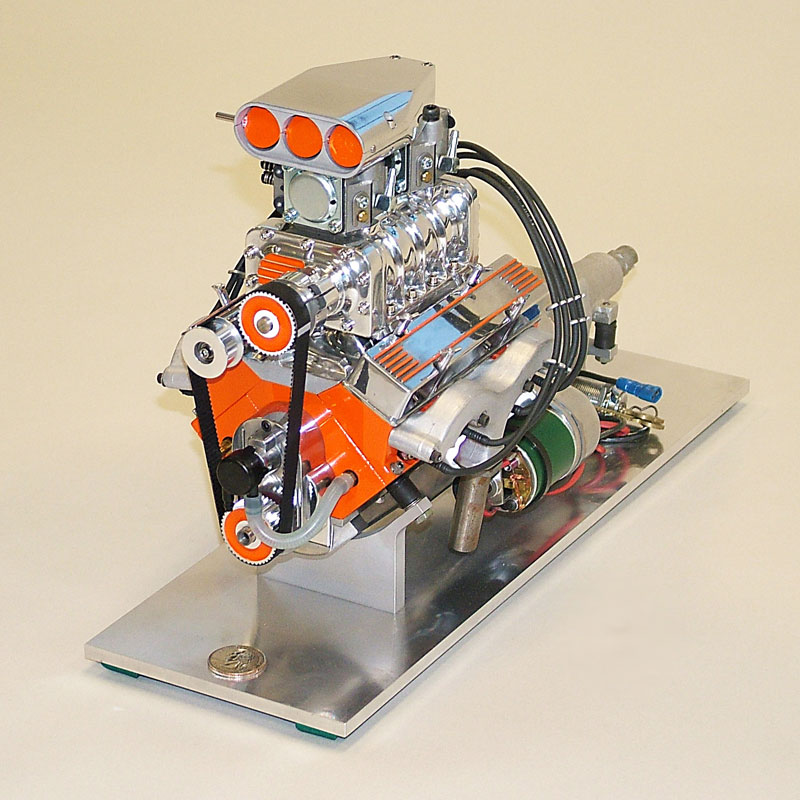

This Conley small-block V-8 engine was designed in 1988 by Gary Conley of Illinois. Paul Knapp built the Conley V-8 shown here in 1993. This engine is 15″ long, 7″ wide, and 10″ high. The methanol burning small-block V-8 was built from the casting kit designed by Mr. Conley. It incorporates a fully functional scale 671 blower with dual carburetors. It will turn approximately 12,000 revolutions per minute at full throttle.

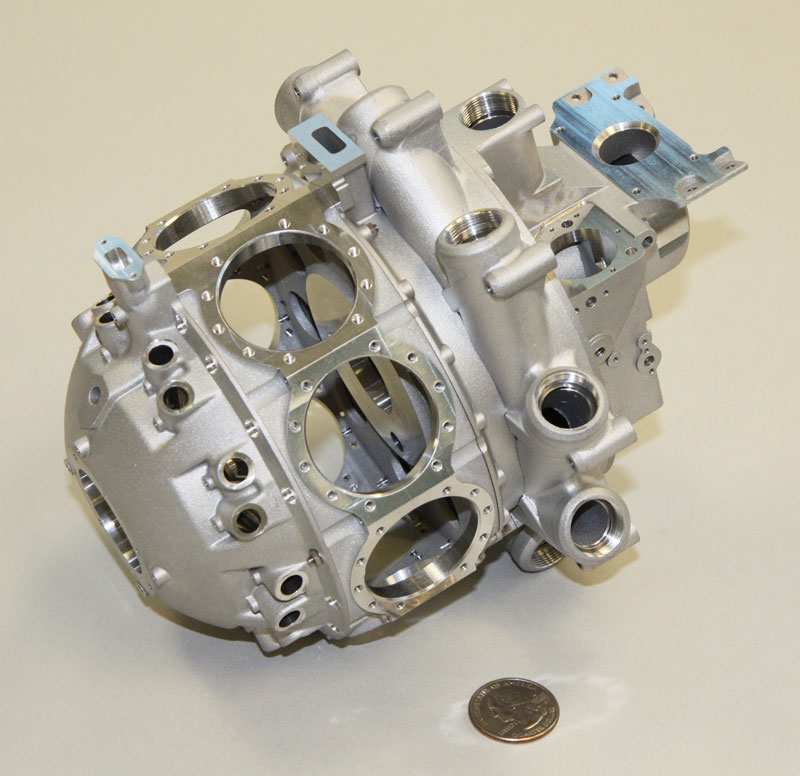

This is a 4-part casting for a 9-cylinder Pratt & Whitney R-985 engine, which reveals some of the craftsmanship that goes into the design of an engine like this. Much of the fine machine work of the basic engine casting is covered up once the cylinders and other parts are bolted on. This assembly represents many hours of work in pattern making, casting, and finished machining.

The display started with just over 50 engines in 2008, and has expanded to include over 200 engines in the past decade plus. In fact, some of Paul’s engines have had to be put into a rotation, as there is simply not enough room for all of his engines to be displayed at once. Regardless, it doesn’t take long to discover one (or likely many) of the engines from Paul’s collection on display in the museum.

For those who can’t come by the museum to see these beautiful engines firsthand, several of Paul’s own engines are featured here, and many more can be seen on the Knapp Collection page. The Knapp Collection continues to grow, and Paul has steadily added more engines to the display at the Craftsmanship Museum.

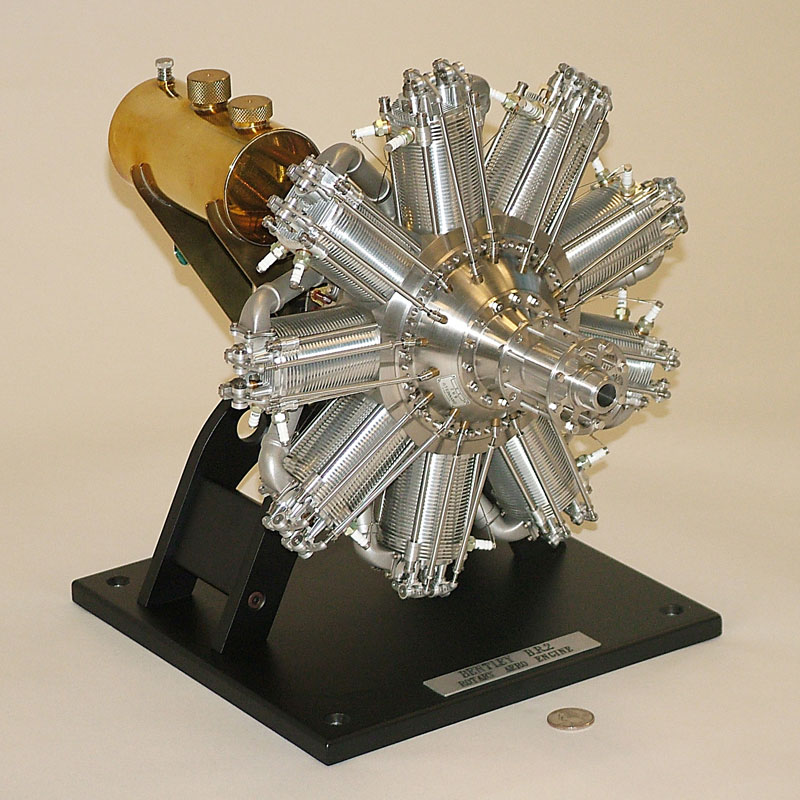

Paul Knapp built this 1/4 scale model Bentley BR2 rotary aero engine in 1993. The engine weighs almost 12.5 pounds without the stand. The dimensions are 14″ long, 12.5″ wide, and 14″ high.

Building a Bentley Rotary Engine and Putting It to Good Use

Mr. Knapp also constructed a model Bentley BR2 rotary engine with the help of Lew Blackmore’s book, Bentley BR2. He also used some CAD drawings by Bill Mazak of Arizona. The engine was machined from stainless steel with aluminum cylinders and heads. The engine burns regular gasoline on spark ignition. It has a pressurized lubrication system and a carburetor just like the full-size engine.

The rotary engines of World War I rotated with a propeller. The hollow crankshaft that extended from the back of the engine was fixed to the airframe, and the crankcase was attached to the propeller. Thus, the crankcase and cylinders rotate with the propeller around the stationary crankshaft.

The Bentley BR2 was produced in England, and it was the largest and most powerful rotary engine used in WWI. It powered many airplanes, most of them biplanes.

Now, Paul actually built four of these engines—two in stainless steel, and two in aluminum. Interestingly, one of Paul’s aluminum versions was used to power Robert Cooper’s model airplane, called the Gigantic, on its maiden flight. Aptly named, the Gigantic has a 12-foot wingspan. Watch a video below of the successful first flight of the Gigantic, with Paul Knapp’s rotary engine powering it through the sky.

This flight purportedly broke two world records on December 4, 2009—it was the first flight by a 1/4 scale rotary engine, and the first flight by a model Bentley BR2. Some different photos show Paul’s engine mounted to the firewall, the plane about to land after its first flight, and then the plane on the ground with everyone involved. Those folks are (from left to right in the photo below): Mac Hodges (pilot), Ray Williams, Dale Calvin, Robert Cooper, and Paul Knapp.

The Gigantic slowly descending after its maiden voyage went off without a hitch. Paul’s 1/4 scale Bentley engine ran perfectly.

Designing and Producing Rimfire Spark Plugs

In 1993, Paul Knapp designed a new 1/4-32 miniature spark plug for the model airplane industry. The “Rimfire” name was derived from Paul’s first design. It was a surface-gap racing plug that performed exceptionally well at high speed, but was too small to retain enough heat at low speed to prevent fouling. After several electrode designs, public demand led to a typical single ground electrode so builders could change the gap for different applications.

In 1994, some handmade samples were sent out to different model racing enthusiasts in exchange for their feedback on performance and/or failures. This valuable information was used to improve performance and reliability as Paul developed his new spark plug. By 1995, Rimfire spark plugs were being used worldwide.

Additionally, many of the spark plugs were undergoing rigorous testing by several aerospace companies like XCOR Aerospace, Austrian Aerospace, German Aerospace, and NASA. The popularity of the Rimfire plugs among members of the model airplane industry, combined with a need for different applications, led to a variety of sizes and styles.

Bill Carpenter, of CH Electronics in Wyoming, produced the most reliable miniature capacitor discharge ignition (CDI) system used by modelers worldwide. In 1993, Mr. Knapp bet Mr. Carpenter that he could produce the world’s best (and most reliable) miniature spark plug to accompany the CH ignition system. The Rimfire miniature spark plug line is the result of that bet.

Several Rimfire spark plug prototypes made by Paul Knapp in Arizona in 1993. The first prototype (left front) is the surface-gap plug responsible for the “Rimfire” name and logo. The logo was designed by the late Chuck Driscol of Mesa, AZ. All of the prototypes and early test samples were fabricated from Macor machinable ceramic.

Visit the Knapp Collection page to learn more about Paul and Paula Knapp’s incredible trove of engines, or visit the museum yourself to see which of the 300 plus engines are on display! The Knapp Collection covers a wide range of engine types, including rotary, radial, inline, Wankle, and “V” engines. The display even includes a model jet turbine! There are also some unique Stirling engines and miniature race cars.