Robert Washburn: Unknown—4/13/09

Frances Washburn: Unknown—7/13/23

Keeping Miniature Internal Combustion Engine Builders Informed and Involved for Over 17 Years With Strictly I.C. Magazine

Recipients of the 2007 Joe Martin Foundation Lifetime Achievement Award

Frances and Robert Washburn—the people behind the publication of Strictly I.C. magazine. The magazine was founded for “MICE” builders, which is an acronym Bob conceived for “miniature internal combustion engine” builders. (Photo: Yuen Lui)

Introduction

In addition to giving out awards that recognize fine craftsmanship, The Joe Martin Foundation also recognizes those who have contributed significantly to craftsmanship by other means. As such, some awards have been given to those who’ve contributed to the craftsmanship world by communicating, teaching, or otherwise sharing knowledge with their peers. For their contributions to the field of miniature internal combustion engine building, through the publication of Strictly I.C. magazine, the foundation is pleased to present a Lifetime Achievement Award to Robert and Frances Washburn.

The following account sheds light on Robert and Frances Washburn’s path to publishing Strictly I.C. After retiring from a career with Boeing, the couple briefly owned a small hobby business. Following that endeavor, Bob and Frances went on to a third career of publishing success. Their magazine brought a diverse group of I.C. engine builders together from around the world, all through one great resource.

Unfortunately, Robert Washburn passed away on April 13, 2009. This profile of the Washburns was written in 2007 for the presentation of their Lifetime Achievement Award. Bob’s guidance and expertise in the field of model internal combustion engine building will be sorely missed by a community of craftsmen among whom he was so well-liked, and highly respected. Sadly, Frances Washburn also passed in July 2023 at the age of 94. Her work alongside Bob was critical to maintaining the wealth of engineering knowledge that was disseminated through Strictly I.C. for so many years. The model engineering community is indebted to the Washburn’s for their unending support of the craft.

The Evolution of Strictly I.C. Magazine

By Robert Washburn

A Little About My Background

Frances and I had left our employment with The Boeing Company in the 1970’s. Frances resigned in 1970 (Frances was a lead in engineering finance), and I resigned the next year in 1971 (I was a purchasing specialist). As a team, we put together a men’s hobby shop here in our city of Kent, Washington. During our hobby days, I became interested in collecting antique model airplane engines (my M.E.C.A. number is still 664-3. I believe their numbers are above 3,000 now). I soon found myself more interested in building internal combustion engines than collecting them.

In 1976, I bought a new Atlas 12” x 36” lathe. Later, I added a milling machine and a surface grinder. Even though I had no prior experience as a machinist, I was able to become a contributing editor for The Home Shop Machinist magazine (H.S.M.), writing a column called, “The Apprentice.” My first engine project was the Schroeder 09 (a single-cylinder engine published in the Engine Collector’s Journal). Although I never got the first engine to run due to lack of compression, by then I was really hooked.

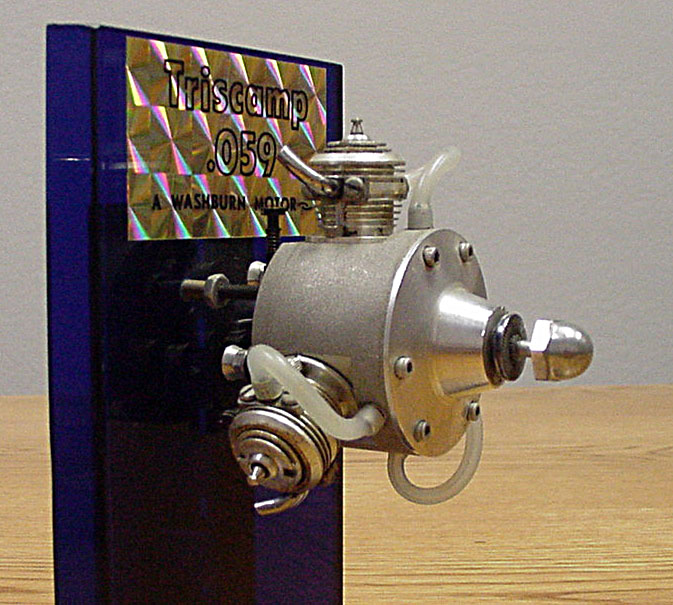

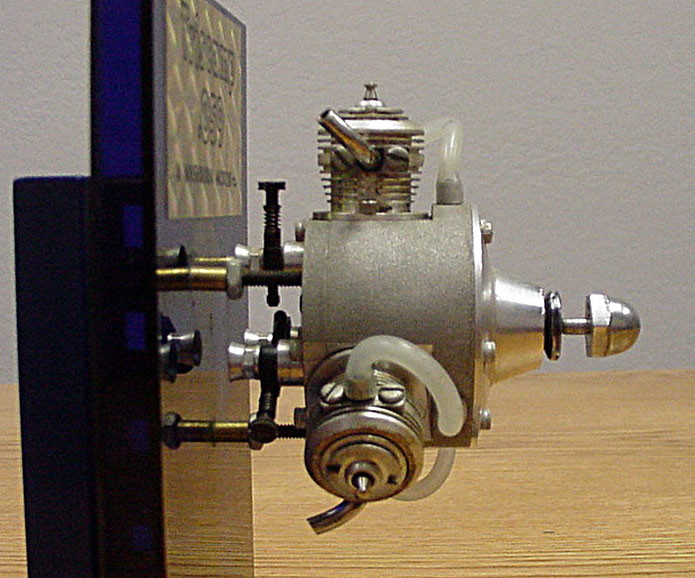

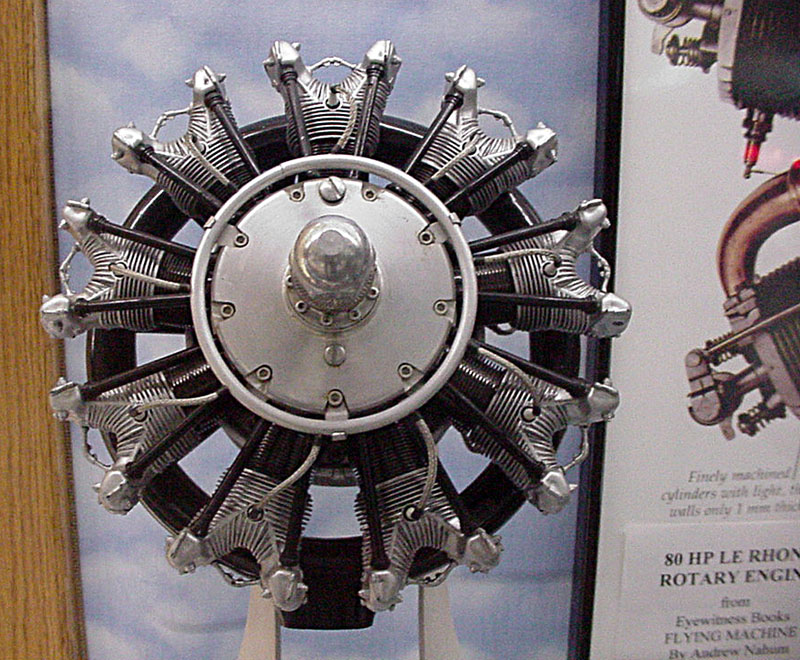

I built two of the late John V. Thompson’s Tarantula engines (a nine-cylinder radial engine). Later, John came out with his V-8 called the Scorpion. I started building one of these, but it was never finished because we started putting together the magazine during those building years. It still sits on top of one of my two reference book shelves today, about 90% finished. Earlier, H.S.M. also published construction articles on two of the other engines I built—the Sky Charger, and my own design of a three-cylinder radial, the Triscamp.

As hobby shop owners and operators, by 1984 we could no longer compete with the discount hobby retailers like Tower Hobbies, who were selling kits at our wholesale cost. On April Fools’ Day, 1984, we closed down the hobby business. We spent the next three years doing something we had always wanted to do—travel the world.

A Beginning in the Publishing Business

While working on miniature I.C. engines at home, and because all the home machining-type magazines were devoted to live steam subjects, in 1987 I decided that the world needed a periodical devoted to building miniature internal combustion engines in the home shop. Frances has always been on my side in all our endeavors. Together, we set out on this new project.

I wanted all of those fellows building miniature I.C. engines in the world to know that they had company. Through our magazine, I wanted to make all MICE builders into a cohesive force. I wanted them to get together throughout the world and ‘talk’ to one another. I believe the magazine succeeded beyond my wildest dreams before France and I became too old to carry on. By the way, we are still disbursing back issues into the world, despite the fact that we stopped publishing!

I relayed my interest in putting out a newsletter for MICE builders to the late Roger Paul, the late Bob Paule, and Bruce Satra. All three said, “Do it. I’ll help.” But instead of publishing a newsletter, on the first issue (Vol.1, No.1) I came up with a 20-page periodical. Later, I enlisted the aid of Roger Schroeder. Along with the other three volunteers, they became our contributing editors. All my C.E.’s were the backbone of all our issues.

On our first of two trips to Australia, in October of 1987, we had the pleasure of being invited to the late Reg and Margaret Wood’s home for high tea and a lunch. Reg was a MICE builder. At lunch, I mentioned to Reg I was going to start publishing a magazine devoted to design and construction of miniature internal combustion engines. Would he be interested in subscribing? Reg became our number 1 subscriber.

Before the first issue was distributed, Bob Paule called and said to me, “I hope you have some subscribers, because writing my column ‘In The Shop’ is a lot of work.” My reply was, “We have 84!” Then I got the idea I should advertise in Home Shop Machinist magazine. This turned out to be a stroke of genius that helped us increase our circulation by about 745 subscribers with the first ad. From there we were off and running.

Before we published Issue No.13, Frances and I made a trip to England. We were to stay one night with the late Prof. Dennis Chaddock, and his wife Stella. Dennis had arranged to take us over to Barry Hares’ home in Birmingham, for a look at the 1/5th-scale, Merlin Mk 20 engine.

Now, this was an overwhelming sight to behold. Words cannot describe this engine. Barry ran the engine for us. It is recorded on our video tape. Before the trip, Frances also took on the task of being the official Strictly I.C. photographer. She asked me what to do with the camera. I said, “You know how professional photographers do it, they take a myriad of shots, then when developed, use the best one.” I relate this incident because on Issue No. 13 we started putting color on both the front and back covers of our magazine. Color covers continued through our last issue, No. 84. The Merlin occupies our first color front cover.

In our publishing house (we did everything at home), I was the publishing department, and Frances was the distribution manager. I put issues together, while making what graphics we used, in order to get issues off to our printer downtown on our deadline. I worked at this full-time every other month. Frances’ work was a daily process, working with incoming new subscriptions, and sending out back issues for those people who wanted to be in from Vol.1, No.1.

All four contributing editors were scattered throughout the USA. Roger Paul was in Rhode Island. Bob Paule was in Missouri. Roger Schroeder was in Kansas, and Bruce was in Utah (later Leonard Woods joined in from Germany). They faithfully sent their manuscripts to us. I would edit them for our use, and proceed to put another issue together. I had to have the color cover artwork in to our printer downtown six weeks before he needed them to put the issues together.

The act of putting covers together was the most daunting task I faced with every color issue. After reviewing photo after photo, and selecting what I would use, I did the layout and associated graphics. When this was accomplished, I would take the mechanicals to our printer to have 5,000 color covers printed.

When we would go off on a trip and come home, we would have a post office carry out tub filled with mail. When we shook off jet lag a day later, we would sit at the breakfast table and sort the accumulated mail into personal and business stacks. After one such trip, we had 110 business envelopes to open. I would slit open all the business envelopes. Frances would scan the personal mail. We would then open and remove content from the business mail, and stack it.

Frances’ work would then begin way before mine. In taking care of the business mail, Frances had to place the new subscribers’ information in her computer (a grueling task, I must say), and get orders packaged to send out to the new subscribers. My task was to start answering correspondence from subscribers. I would set aside three or four days to accomplish this after every trip.

Robert built this Thompson Tarantula “9-engine” radial model aircraft engine, circa 1980. He built the engine from drawings supplied by John Thompson, which Robert received while writing construction articles for Strictly I.C. The Tarantula consists of nine Cox .049 1-cylinder model airplane engines, all geared together in an aluminum crankcase. The crankcase is housed within a plastic Williams Brothers Pratt & Whitney R-985 model engine kit. The nine engines are geared so that all cylinders fire at the same time. The engines actually run cool enough so that they don’t melt the scale cylinders of the plastic kit surrounding them. It’s an interesting way to build a scale-looking engine using a minimum amount of custom-machined parts. (Photo and description courtesy of Paul and Paula Knapp.)

When our printer delivered some 3,000 copies of a new issue, using my garden tractor and a long trailer I built, I would haul the issues down to an area outside our daylight basement bar. In readying an issue for mailing, Frances started first. She would print a label for all current subscribers. She would separate the foreign subscribers from domestic. She would stuff an issue into an envelope for the foreign, and put the necessary postage on each. That would start on Wednesday after the printed issues arrived.

On Friday afternoon, we would sit opposite each other at the table in the bar. I had already brought the 19 cartons of issues inside, placed half of them on her side of the table, and half on mine. We would then separate the mailing label run into two halves. There we both sat the rest of the afternoon, all day Saturday, and Sunday morning—until the mailing was completed. The process involved placing an issue into a polyethylene bag, sealing each, placing the mailing label on each, and boxing them by USA postal distribution centers. By Sunday afternoon we were both bushed.

In order to get favorable postage on each issue, we had to sort each poly bag into mailing zones. I would take boxes of these into my shop and put them into mail bags. I would tag the bag as to its destination. When I got a trailer full, I would haul them up to the garage and put them into our station wagon. By Sunday afternoon the wagon was full; all bags were in the wagon ready for the trip to the post office on Monday morning. Delivering them there would rid ourselves of another issue for a couple of weeks for me, but Frances had to continue caring for new, incoming subscriptions.

So, you can see why this was an all-out team effort. It was only the two of us doing our thing here at home on each issue.

What’s Next

In 1994, I started to miniaturize a 6-cylinder, horizontally opposed, dual overhead valves, full-blown (Roots blower), fuel injected, electronic ignition race car engine. I’m still working on it today; albeit progress is really slow now with my breathing malady. Again, I had been putting magazine issues together during the time I was initially working on the engine. One day in 1994, I got a call from an A.J. Mobley, who claimed to be associated with the Indianapolis Motor Speedway. He said he had something I might be interested in, and was willing to trade it for something I had that he wanted—a set of original plans for an Offenhauser 150 engine.

What he had to offer was a set of plans for a future engine project, produced by a consortium of engine builders who wanted to bring the Offenhauser name back into competition at the ‘Brickyard’ speedway. Somewhere along the way they ran out of money or enthusiasm, and the project was dropped—but an interesting engine had been designed. His proposition sounded interesting, so we made the trade.

The actual six drawings I ended up getting were of two engine designs, and they were assembly drawings, not construction drawings. The one that I chose turned out to be the engine I described above; a race car engine. I assigned the project the name of OFFYSIX. As far as I can tell, no other real-world prototype had ever been attempted from the mechanical drawings. (I was offered a full set for US $3,500.00, but declined).

While still publishing the magazine full-time, in 1994 I polished my AutoCAD skills by producing 1/4 scale drawings from the set I had received in the trade. During that time, I was also able to produce the crankcase, the cylinder sleeves, engine blocks, a gear box, 13 gears to operate the dual overhead cams, and two oil pressure pumps for OFFYSIX. During our tenure in publishing, based on some of the construction articles we published, I had also built a dynamometer, a crankshaft grinder, and the EDM.

On OFFYSIX, I have had some help of late. A friend in Holland, Hans Mulder, asked if he could produce the cast pistons for me. A friend in Detroit, Bud Kirk, asked if he could produce the connecting rods. (They are beautiful.) Later, he asked to machine the pistons and piston pins. To all these helpers I always say, “Yes. I’ll take help anywhere I can get it.”

That’s where I am today; still working on the project, and hoping I live long enough to finish the engine. I would sorely like to put the engine in a Formula 1 race car, but am having a hard time finding out how those guys build their little beasties. I have bought books, I have searched the internet, but these guys seem to not want things to get out. I don’t care what Formula 1 car it is (as long as it can be configured to accept a flat, six-cylinder engine), I don’t care what year it is, I don’t care who produced it! I just need help in configuring a 1/4-scale Formula 1 race car.

—Robert Washburn

Though best known as a magazine publisher, Robert was also an innovative builder. All of the engines pictured on this page were built by him. These engines are now part of the Paul and Paula Knapp Engine Collection, and can be found on display at the Miniature Engineering Craftsmanship Museum. We thank Robert and Frances Washburn for their tireless dedication to Strictly I.C. magazine. Their contributions to the field of miniature internal combustion engine building are immeasurable.