Building a Complete 1932 Duesenberg in 1/6 Scale

Recipient of the 2009 Joe Martin Foundation Lifetime Achievement Award

Recipient of the 2011 Joe Martin Foundation Craftsman of the Decade Award

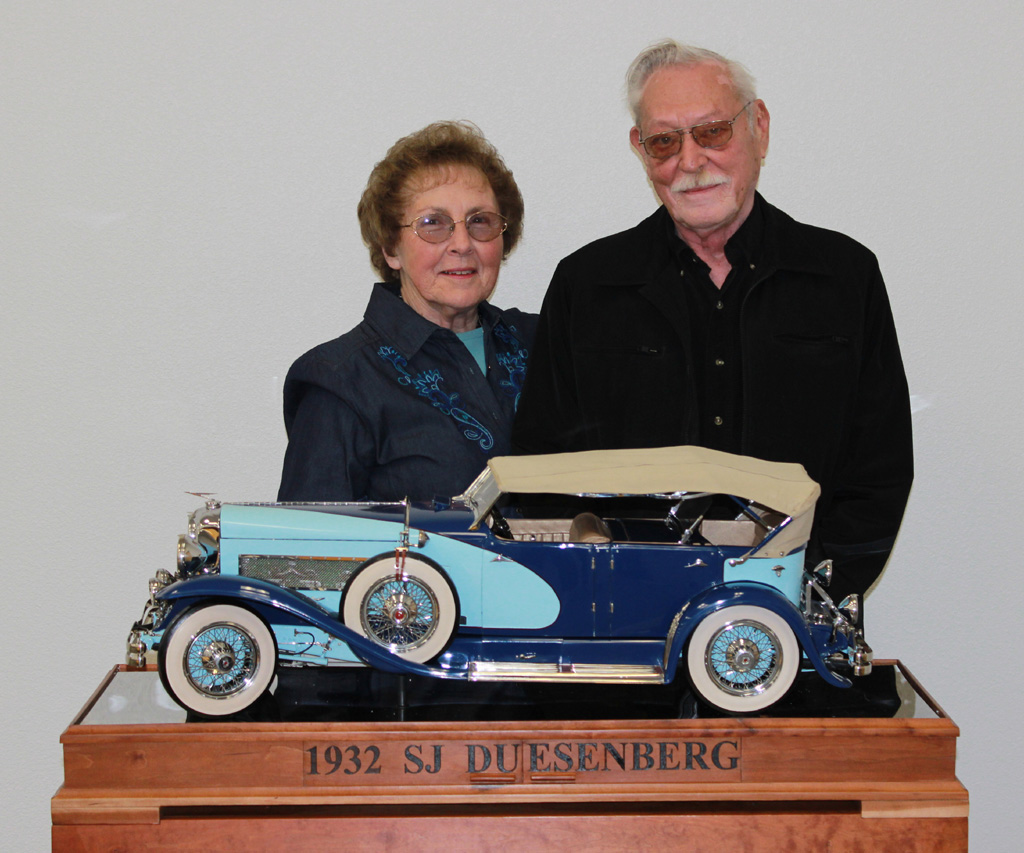

The Joe Martin Foundation selected Louis Chenot for the Craftsman of the Decade Award in 2011. His award was presented on April 30th at the NAMES Expo in Southgate, MI. Lou is seen here with his wife, June, as he was presented with the award by Craig Libuse, Director of the Joe Martin Foundation.

A Multi-Year Project to Build a Complete 1932 Duesenberg in 1/6 Scale

For many years running, one of the first things that attendees of the North American Model Engineering Society (NAMES) Expo would want to see upon arrival was the progress that Lou Chenot was making on his marvelous Duesenberg project. As a result, most of those attendees (including members of the Joe Martin Foundation) were able to see the project develop in one-year bursts, with new major components being added each time. It was a reminder that each new stage of the Duesenberg represented a full year of work on Lou’s part. As the project continued to take shape, with the engine near completion and the bodywork beginning to form, everyone was amazed at the masterpiece being created. A project like this requires the mastery of so many skills that it stands head and shoulders above the rest.

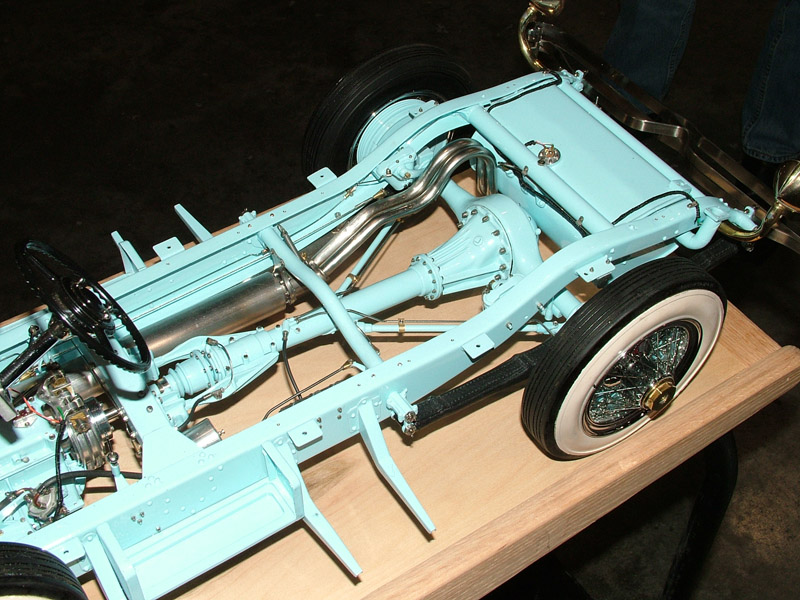

The Duesenberg is not just a model—it is a complete car in miniature. In March of 2010, the engine was successfully run for the first time, and just about every feature that worked on the real car also works on Lou’s miniature version.

The finished Duesenberg was shown for a year and a half with the engine out, so that Lou could run it on a test stand for show visitors. In 2012, the engine was reinstalled in the body and shown a few times as a complete car. However, for practical reasons the engine cannot be run when mounted inside the car. Lou began working full-time on his 1/6 scale Gar Wood speedboat, with Liberty V-12 power, and no longer wished to travel the country showing the Duesenberg. The heavy model was difficult to transport and set up, and it often required repairs after the stress of travel and display. In December of 2013, the Joe Martin Foundation had the singular good fortune of acquiring this world-class model for permanent display in the Miniature Engineering Craftsmanship Museum in Carlsbad, CA. The public is invited and encouraged to come view this masterpiece in person.

My Duesenberg

By Louis Chenot (Updated 6/07)

(The following is from an article that appeared in the Auburn Cord Duesenberg Club Newsletter, Vol. LIV, No. 10, 2006. It was written while the model was still under construction.)

When about five years old, I began building models and continued off and on all my life—cars, airplanes, boats, trains, finally learning about 25 years ago that people were building models that actually ran under their own power! Some simple models followed, with steam power leading to an 1895 American-LaFrance fire engine, a 9-cylinder Bentley rotary aircraft engine, and finally the Duesenberg—beginning about six years or 15,000 hours ago.

It was necessary to earn a living until retirement. The above early interests had led to several years in the Air Force as a jet engine mechanic, and then a 40-year career in mechanical engineering—the last ten as Director of Engineering of the Leggett & Platt Corporation Automotive Group. After that, it was on to becoming a full-time model engineer.

J.L. Elbert’s “Duesenberg” book was purchased in 1955, followed by acquiring anything I could about the car. I was around them in the early 60’s when we had a 1930 Cadillac convertible used in Grand Classic contesting (a seven-year restoration).

When the decision was reached to model the Duesenberg, June and I made a trip to the Auburn-Cord-Duesenberg Museum in Auburn, Indiana. Jon Bill helped me through the drawers of drawings, pulling about 60, which he had reproduced. They were the basis, although about half weren’t applicable. When traveling to Auburn, stops at the restoration shop of Charles Glick in Paris, IL also proved very informative.

June and Louis Chenot stand behind the new exhibit for the 1/6 scale Duesenberg at the Miniature Engineering Craftsmanship Museum in December, 2013.

Upon learning about Brian Joseph’s Classic and Exotic Car Service in Troy, MI, I telephoned and asked if I could visit. This was the first of twelve or so trips there, with Brian allowing me to remove parts from inventory, photographing and measuring them, and, of course, answering questions and later telling me the model was out of scale here or there. He was very much a mentor on this project, and it is difficult to thank him sufficiently for his time and consideration.

Visits were also made to Randy Ema’s shop in Orange, California where he verified from record the last “J” number and frame number—hence my use of J-589 that is now the last operating Duesy built. He has an eight-branch exhaust manifold that I scaled, and I was able to note detail from a supercharged engine belonging to Jay Leno in Randy’s shop. Jay allowed photographing and detailing from his roadable chassis, an appreciated courtesy. Skip Marketti, with the Nethercutt Museum, helped on supercharged engines and answered questions during two visits there. He offered the compliment of exhibiting the model in the museum at some point.

Bill Miller has graciously permitted the measuring of body contour from his LaGrande Dual Cowl Phaeton. A unique project does require research and help from many, doesn’t it?

Data from the research trips needed to be reduced to scale, sketched, and dimensioned. I don’t formally draft any more than necessary and use CAD minimally. The sketches are scribbled all over during part production, and finally corrected to what I actually did!

Following the research stage, much time was spent building tooling: jigs, fixtures, cutters, ad nauseam, to where typically more time is invested in preparation than in making parts. I often wondered if the engine really needed 32 valves, couldn’t 16 do? At some time in the future I wish to have a meeting with Fred and his designers, and ask why it had to have all those parts.

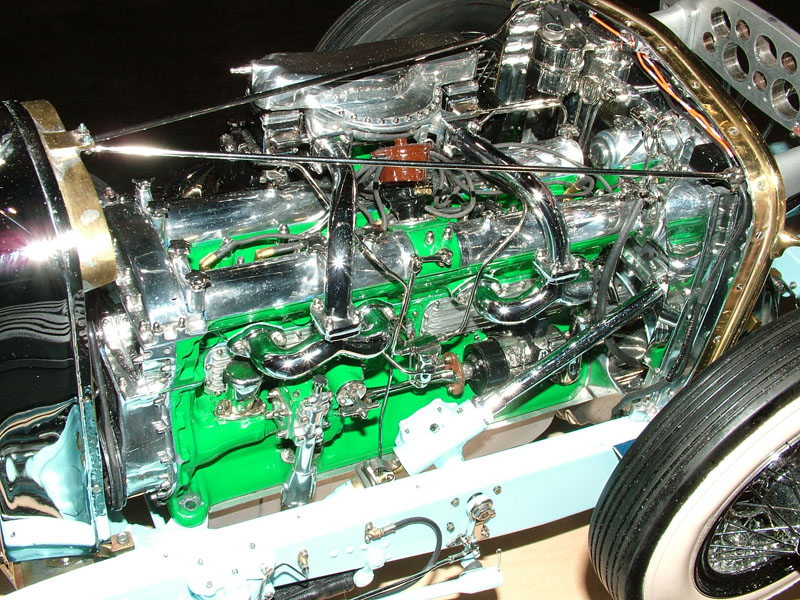

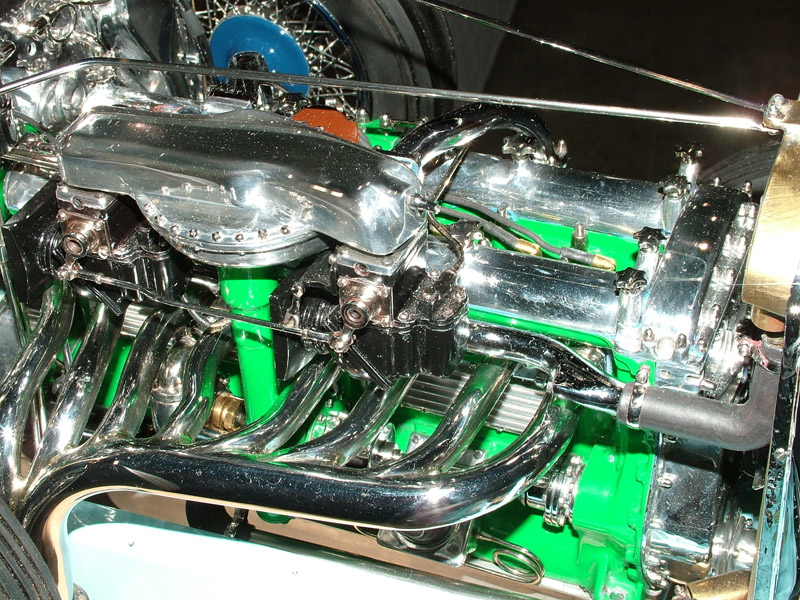

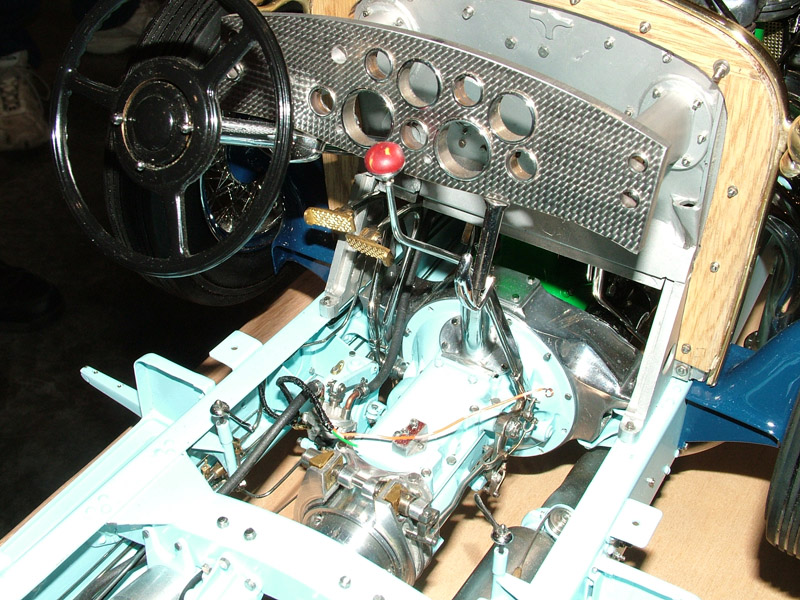

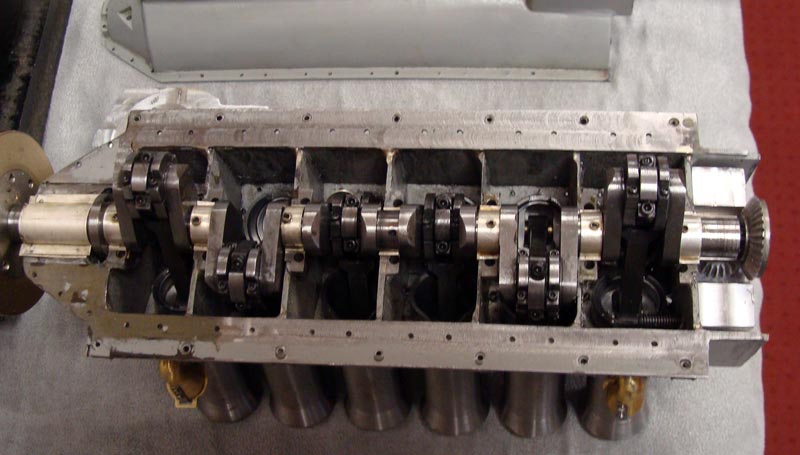

These images show the 1/6 scale Duesenberg engine after installation.

With a 5-year history, and perhaps 2 years to go, it should be running by year’s end. That will be exciting or truly frightening. It has over 6000 parts (966 in the wheels and over 300 in the head, for example.) Most fasteners had to be made, and all are stainless steel. It is very much built from raw materials. Unfortunately, there is no 1/6 scale Duesenberg store to go to for shopping.

My basic drive seems to be learning how to make something where skills must be developed. This also indicates how large my development bin is. (Some use the vulgar word scrap, but even unusable Duesenberg parts are to be revered.) It doesn’t bother me a great deal to start again on something if it isn’t suitable—nine starts were made on the radiator shell!

After restoring our 1930 Cadillac (sold long ago), and supporting friends owning Packards and other large cars of that era, I am still amazed at how advanced Duesenberg’s engineering was for 1928.

Our experience with the Auburn Cord Duesenberg Club at the ACD Festival in Auburn, Indiana over Labor Day weekend was a trip June and I will remember. We weren’t certain how to exhibit the model, or even if it would be welcome, but the members settled those issues quite quickly. I hope the model is a credit to their cars.

—Lou Chenot

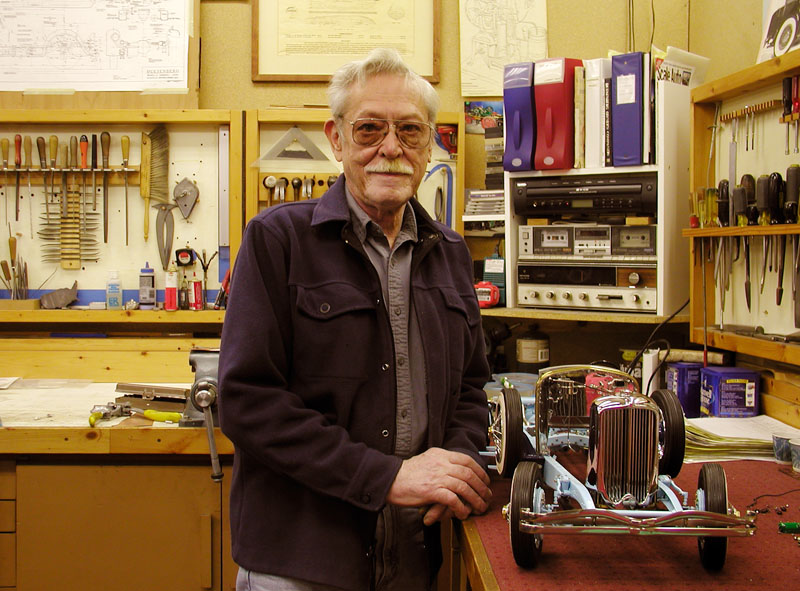

Lou Chenot’s Shop

Lou Chenot’s shop is well equipped for model work, including a 12-inch lathe that is 24 years old, modified in many ways, and very accurate. A Bridgeport-type mill was installed, which some of Lou’s friends think is silly because it runs 1/16″ cutters very often.

Many auxiliaries were built, including: a horizontal and vertical index table (4″), tube benders from 1/16” to 1/4” x 1/32″, a Quorn tool and cutter grinder, and a 1” x 42″ belt sander that is used daily—if not hourly.

The shop also has some other machines which are rarely used, such as a 7″ South Bend shaper, and a 7” Atlas horizontal mill—but they were restored and look great! Lou’s shop area occupies about 800 square feet and is carpeted. It’s nice to have additional custodial help from his wife, June, who is also the chief cook, gardener/landscaper, and secretary/typist.

June also finds time to enjoy her garden railroad, and the little white American Eskimo dog they adopted from their son. The back shop (dirty area) was designed for woodworking equipment, welding, investment casting, blasting, garden railroad work, and storing the lawn tractor. This equipment is stored in heated/air-conditioned comfort, along with a full-size Continental aircraft engine. It is about 1,500 square feet.

When the Duesenberg was being built, you could find Lou in his shop seven days a week, 8-10 hours per day, and looking forward to each and every one of them. Now, while working on the Gar Wood project, Lou is relaxing his schedule a little bit—but he still works in the shop every day, starting first thing in the morning.

Lou’s well-organized shop, featuring a lifetime collection of fine tools, a carpeted floor, heating, air conditioning, and plenty of light.

Lou Chenot accepting his Lifetime Achievement award from The Joe Martin Foundation’s Craig Libuse at the 2009 NAMES Expo in Toledo, Ohio, on April 18th. The award included a check for $500.00. Lou’s Duesenberg was also the featured project at the 2009 NAMES Expo. In this photo, the body had yet to be painted, and the engine was not yet running. It has since been completed!

Duesenberg Model Completed!

By Lou Chenot (10/14/10)

The Duesenberg is hereby declared finished! It started for the first time at 3:05 PM on March 15th, 2010.

The engine has turned out not to be a docile, friendly mechanism. It requires a drill motor at 2,500 rpm to start it, which in turn needs a power cord. I’ve started it many times, and it must consistently be rotated 30 sec or so until it is warm enough to self sustain, where it will re-start easily. Its rpm range isn’t very great, top end at 4,100 down to maybe 2,000.

Propane is the fuel. It has scale carburation now, and more of its shiny bits. I’ve decided to keep the engine on its stand and run it at the Cabin Fever Show in York, PA (January, 2011), and then NAMES (April, 2011)—after which I’ll install it in the car and not run it again. We will take another video of the engine and the car, body off, then add back pieces so they can be described.

—Lou Chenot

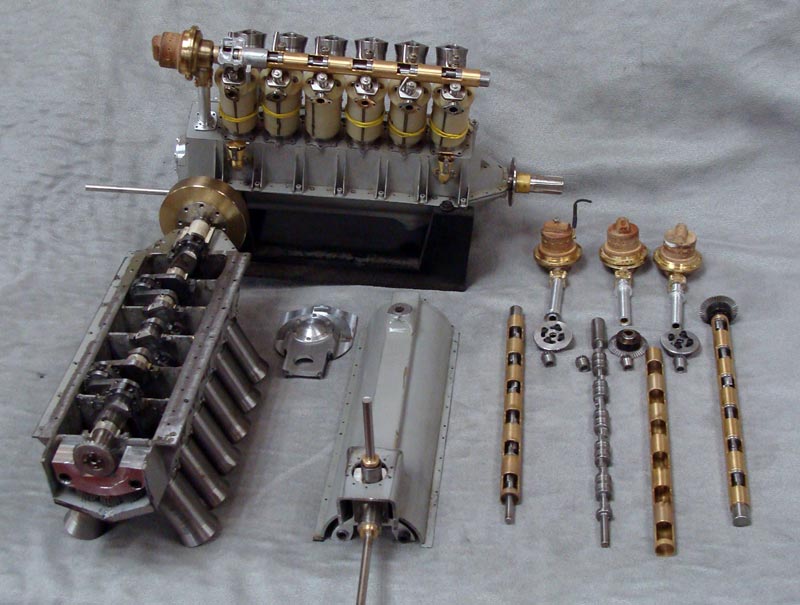

The model Duesenberg’s 1/6 scale Liberty V-12 engine sits outside of the car. The straight-eight engine has four valves per cylinder, just like the full-size version.

Video of Lou’s Duesenberg

Watch the “first pop” of the Duesenberg engine below.

Watch the last running of the Duesenberg before the engine was installed in the car for permanent display. (9/2/11)

Watch a video of the Duesenberg chassis and engine running at the Cabin Fever show.

This photo shows how passengers could enter the rear seat area by swinging up the cover that goes over their legs when down. Lou’s beautiful miniature spares no detail.

Lou’s Next Project—a V-12 Powered Wooden Speedboat

By Lou Chenot

That said, and while a bit disappointing, my energy is now directed towards Liberty V-12 aircraft engines marinized to power lovely triple cockpit mahogany-hulled speed boats from 1920–1940. They were an inexpensive 500-HP engine. I’ve been corresponding with people around the country trying to find lofting data for a Model 50 Gar Wood hull, and because information on the Liberty is on hand, I’ve started on the crankcase. (That is, Crankcases—I’m building 2, don’t ask why.) This is going a bit slowly because of having to recover from back surgery (spinal fusion). The boat itself will be built in 1/6 scale, the same as the Duesenberg. Even so, the 33′ Gar Wood will be 5′-4″ long in that scale!

Early progress on Lou’s 1/6 scale Liberty V-12 engines, shown here on display at the NAMES Expo in Southgate, MI.

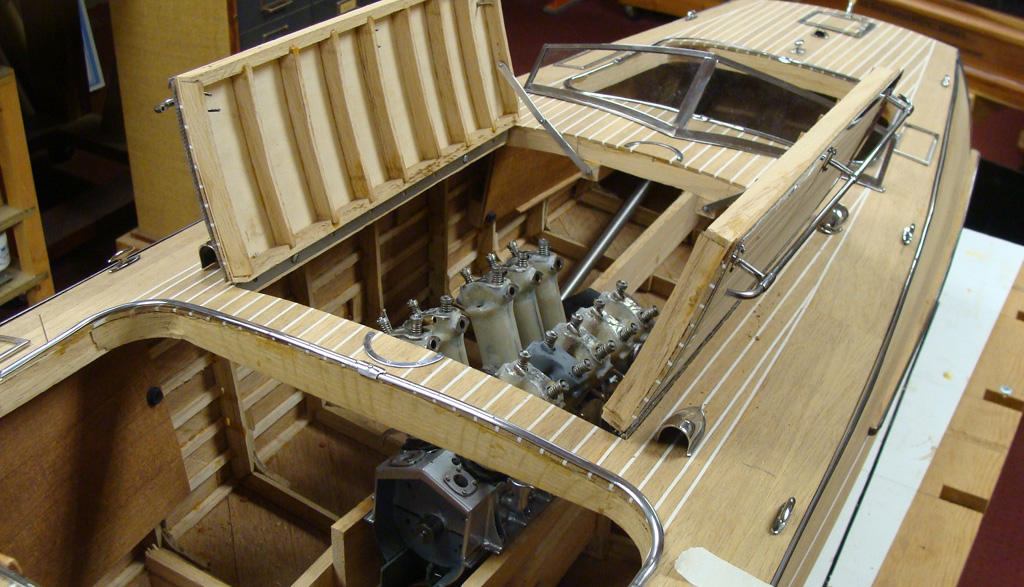

Building a Gar Wood 33-Foot Runabout in Miniature

Shown in the photographs below is a Gar Wood model 33-50. According to Tony Mollica’s charts in his book, Gar Wood Boats, only 2 were built. It was the smooth deck replacement for the Baby Gars built in the 1920’s.

The truth, however, is that this is a model built in 1/6 scale. The Gar Wood was chosen because Garfield Wood favored the use of marinized Liberty aircraft engines, for which detailed information was available—especially with the publication of Robert Neil’s wonderful book on these engines. Research is time consuming for such a project, help is necessary. Don Dannenberg, Tony Mollica, Gary Worthington, Hal Orchard (who has a replica of the boat), and the publisher of this magazine all provided support.

To build a high scale functional miniature requires much detailed knowledge, and then design changes—mostly internal—to comply with the statement that nature doesn’t scale very well. Spark plugs will be 6-40 threaded, .138 diameter, and about 1/2” high. They need to be about 10,000 volts to fire, just as full-size does, so spacing of electrodes must be managed. The engine will operate only one set of plugs, which helps that problem, although twin plugs per cylinder will be installed. Water jackets that were cast to shape should be metal, but spark plug proximity caused the choice of high-temp epoxy to avoid spark jumping.

The engine has 12 gears at the back end—all bevels. Of those, 9 drive the cams and distributors, then 3 go downward to the oil and water pumps. It is intended to build an intercooler so that the engine will have a closed coolant system with pond water only used to transfer heat.

The photographs may cause the appearance of the engine being assembled, but it is only temporary. Much fitting will be required, and I will need to run in the bearings that are .013″ in silver sheet stock. The crankcases are steel fabrications because of the section thinness, silver-brazed, and TIG welded. Oh yes, there are two engines! The boat needs only one, but because of so many tool setups (jigs and fixtures) on machine tools, the second probably required half the time of the first. Either that is the justification, or it is simply a lack of common sense.

The mahogany boat hull was sawn from one plank, as were the white oak framing pieces. The bow and stern deck sections are removable because the intent is to radio control this miniature. There isn’t a straight piece of wood in the hull, with much fitting being required. It is 5-1/2 feet long.

The project has been going on for 2 years now, and no doubt has that much time remaining. Prior to this, 10 years were spent building an operating 1/6 scale 1932 Duesenberg! Why do this? Miniatures are fascinating in their own right, and apparently the everyday effort keeps me alive and well, sort of.

—Lou Chenot

1/6 Scale Gar Wood Now on Display

After six years of labor, Louis Chenot has completed his scratch-built 1/6 scale Gar Wood 33-50 Runabout. Along with the boat itself, Mr. Chenot also finished and installed the 1/6 scale V-12 Liberty marinized aircraft engine. All told, the project took 12,000 hours to build, and the hull alone took five months to complete.

Over the course of its construction, Lou gathered enough research materials and photos to fill two large binders. This included original drawings, patents, plans, and sketches among other material. Mr. Chenot was gracious enough to donate this first-rate scale model to the Miniature Engineering Craftsmanship for permanent display. Come by and see the remarkable miniature boat and V-12 for yourself.

The impressive wooden runabout was built from a single plank of mahogany and a plank of white oak. Lou went to great lengths to ensure that his model was planked and built just like an original Gar Wood.

Along with finding as much documentation as he could, Lou also consulted at least one person who restored full-size boats to be certain that his work was accurate. Not only did Lou build the V-12 Liberty engine inside the model runabout, but he also built a second V-12 engine which was donated along with the model (although unassembled).

The Gar Wood model features a polished wooden finish, fully upholstered seating, windshields, working latches, and most other features found on the original runabout. Demonstrating some ingenuity of his own, Lou decided to set up the battery so that the switch would be initiated by pushing in a flagpole on the deck to turn it on.

The full-size Gar Wood runabout that Mr. Chenot based his model on was 33’-long and built in 1930. The original boat is in good condition (formerly known as “Wampum,” now called “Heather”). A photo of the full-size Gar Wood is shown below.

The model Gar Wood was planked in the same manner as the original and has all of the bells and whistles. Interestingly, Lou set up his model so that the battery could be initiated by pushing in one of the flagpoles on the deck.

The Gar Wood brand was founded by Garfield Arthur “Gar” Wood (December 4, 1880–June 19, 1971), who was an American inventor, entrepreneur, and championship motorboat builder and racer. In fact, Mr. Wood was the first person to ever travel over 100 mph on water, and he held the world water speed record several times. Following his early successes in racing, paired with several profitable inventions, Mr. Wood founded Garwood Industries, which built racing and pleasure boats.

Perhaps the most famous of these boats were the Liberty V-12-powered 33-foot “Baby Gar,” built in the 1920s and early 1930s. During WWII, Garwood Industries also built target craft and tugboats for the US Navy. Despite advances in boat building technology after the war, the company continued making its traditional all-wood boats until 1947, when it halted production. Today, Gar Wood boats remain among the most sought after classic boats in the world. It’s estimated that over 10,000 Gar Wood boats were built.

The Liberty engine was originally designed by Jesse Vincent and Elbert Hall for the US Army in 1917. After the war, these lightweight, powerful engines were plentiful and inexpensive. Gar Wood purchased 4,500 of these engines and launched the Detroit Marine-Aero Engine Company, converting aircraft engines for marine use. They became the first choice to power high speed boats in the 1920s.

The miniature Liberty engine is about 8-5/8”-long, 6”-high, and weighs approximately 16 lbs. The engine sits in a frame that was modified to fit in the boat hull.

Mr. Chenot also submitted some information on the original full-size Liberty engine specifications:

- 450 hp at 1,950 rpm

- 12-cylinder, V-type 5”-bore, 7”-stroke

- 1,650 cubic inches; 1,350 lbs.

- 1.25 to 1 Overdrive

More photos of Lou’s construction of the runabout can be found at the link at the bottom of this page.

Lou Chenot has produced a large volume of extraordinarily high quality work. We have provided more photos than normal as a teaching experience. Certain craftsmen set the standards in their area of expertise. Studying the details of their work can be helpful for anyone wishing to follow in their footsteps, or to take their own work to the next level. We hope that those interested in achieving this level of craftsmanship will find Lou’s extensive photo page both instructive and, hopefully, inspiring.