Harley-Davidson Knucklehead Motorcycles in Perfect Scale

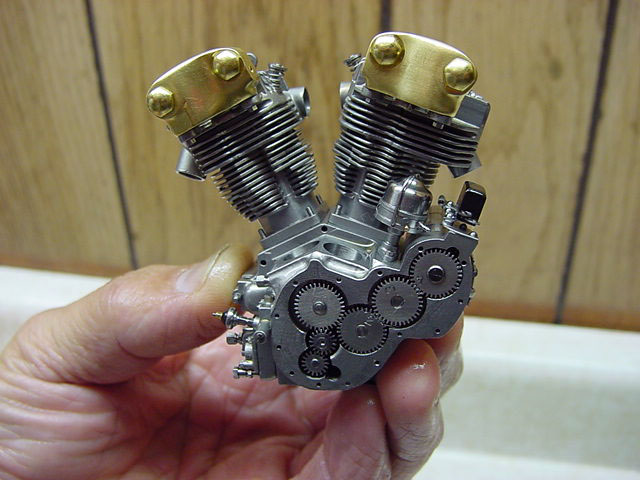

With the cam cover removed from Jerry’s 1/8 scale version of a Harley-Davidson knucklehead engine, all four cam gears can be seen.

Jerry Kieffer prefers to work from the real thing when building his scale models. In this case, he actually owns a 1947 Harley-Davidson “Knucklehead” motorcycle, which he completely restored. As such, Jerry can measure each and every part of the real bike to make scaled down parts for his models. His goal was to model the entire motorcycle, get the motor to run, and have all other systems working. Jerry started with a 1/6 scale model, and built the entire engine. The miniature motorcycle engine is completed and runs fine. However, after thinking about the project, Jerry realized that modeling at 1/6 scale would produce a finished model too large for his liking.

Rather than continuing on, he left the first engine as a running display model, and started over from scratch in 1/8 scale. The second motorcycle is virtually finished after years of work, and stands as yet another example of Jerry Kieffer’s master craftsmanship. Below, photos of the scale motorcycle projects illustrate the lengthy and complex construction process over the years.

Jerry’s first knucklehead engine is a 1/6 scale version of the original, and actually runs and sounds like a Harley. It was machined from bar stock, and no castings were used. The oil pump, sending unit, distributor, generator, and regulator are also functional. The cylinders would eventually be painted, and the brass areas were nickel-plated like the original.

Now, one of the ways that Jerry challenges himself is to announce beforehand what he intends to accomplish. However, those proclamations can be regrettable at times when he runs into seemingly insurmountable problems with a build. Even so, the pressure of following through on his promise motivates him to work at a problem until he finds a solution, rather than simply giving up.

In the case of the scale motorcycle, Jerry stated that he wants to be able to start the tiny engine with a kick starter—just like the real thing. He also wants the gearbox to function, and to have a working speedometer. These are some incredible goals when considering the small scale of the bike. Duplicating all the parts for a transmission, or a speedometer and drive in 1/8 scale is quite a challenge.

Many of the parts are hard enough to make at full-size, let alone 8 times smaller. Keep in mind that when reducing in scale, the part size gets smaller as a function of the cube root of the volume. It is not a simple linear reduction. For example, the volume of a part at 1/2 scale is actually 1/2 length X 1/2 width X 1/2 height. That means that the 1/2 scale version of a 1” cube would be .125 cubic inches—or 1/8 of a cubic inch. A 1/8 scale model of a 1” cube is .125 X .125 X .125, which equals .00195—less than 2 thousandths of a cubic inch!

1/6 Scale Harley-Davidson Knucklehead Engine Model

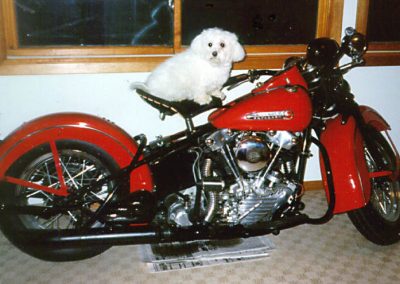

Jerry’s Original Knucklehead

This is the full-size 1947 Harley-Davidson Knucklehead motorcycle that Jerry restored. Jerry’s dog poses in the sprung seat. The bike is show quality, and is not ridden because there are zero miles on the NOS speedometer. Jerry has been using this bike as the prototype for his models. Each original part is measured and duplicated in miniature.

1/6 Scale Knucklehead Cylinder Barrels

Cylinder barrels for Jerry’s 1/6 scale Knucklehead engine. These miniature parts illustrate some of Jerry’s talent with metalworking. The full engine is complete and running. This pair of cylinders came from an early version that Jerry later decided needed some modifications, so he made them over. The pair can be seen on display at the Miniature Engineering Craftsmanship Museum in Carlsbad, CA.

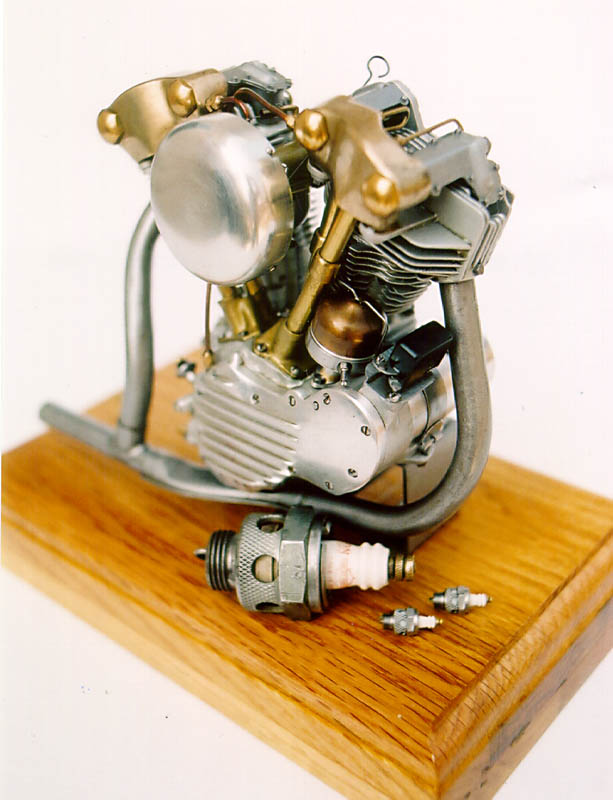

1/6 Scale Knucklehead Engine

Placed beside the engine is a full-size, air-cooled spark plug, compared to two 1/6 scale spark plugs used in the model. Jerry decided to make a model of the complete motorcycle, but felt that this engine was too large. So he started from scratch on a 1/8 scale version, which is detailed below.

1/8 Scale Harley-Davidson Knucklehead Motorcycle

The following photos show Jerry’s progression on the 1/8 scale Knucklehead.

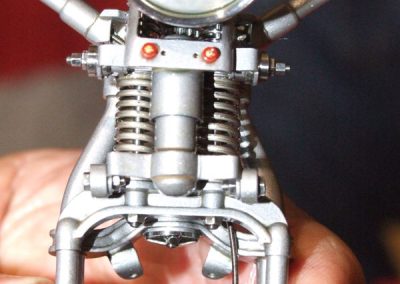

1/8 Scale Knucklehead Engine

The 1/8 scale Knucklehead engine is coming along. At this stage, the pushrod tubes and cam cover are in place. The intake manifold and carburetor are also installed.

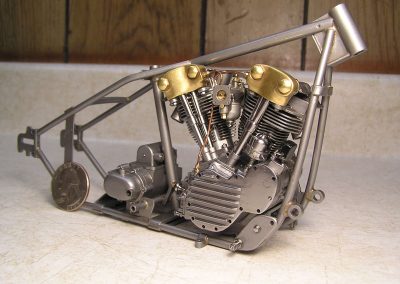

1/8 Scale Knucklehead Engine and Frame

Jerry’s small Knucklehead engine and some other components sit next to the frame, which has the transmission installed.

1/8 Scale Knucklehead Frame

The engine and transmission are installed in the frame. The Harley frame, which is made completely from metal, is so perfect that show goers occasionally ask Jerry, “Is it made out of plastic?” He simply smiles and replies, “No,” Understanding that it was not meant as an insult, but in fact a complement to the quality.

1/8 Scale Knucklehead Components

A closer look at the kick starter, internal gears, and other transmission parts. A quarter in the foreground provides scale reference.

1/8 Scale Knucklehead Engine

One problem with building a running engine this small is that not everything can be scaled down. Engine compression is one of those things. If you scale down all the parts of the original kick starter system, but keep the compression near that of the original, the tiny parts can’t handle the load. The primary cover is in place on the engine here.

1/8 Scale Knucklehead Engine

With the primary cover removed, the gear set is exposed. This photo gives a glimpse of Jerry’s solution for beefing up the kick starter mechanism to handle the compression. Behind the gears is a ratchet setup, which turns the engine over when the kick starter is pushed. With the cover back in place, nobody can see how it’s done.

Knucklehead Clutch Cable

The clutch cable was made using a special fixture, which was designed and turned on a Sherline lathe. The lathe was also used to wrap the wire for the outer cable using the same fixture. The inner wire that actuates the clutch is .010” in diameter, and slides freely within the outer cable housing. The housing was wrapped using .007” wire, and has an outer cable diameter of .032”. It took several attempts, and weeks of work, for Jerry to design a wrapping fixture that worked—but his final fixture works very smoothly.

1/8 Scale Knucklehead Kick Starter

One key goal that Jerry has for this project is to be able to kick start the bike just like the original. However, this requires overcoming several engineering challenges because of the small size.

1/8 Scale Knucklehead Kick Starter

This is the kind of hidden engineering that separates real engine modelers from the “instruction followers.” Here is how Jerry’s kick starter mechanism works: In this first photo, the rack gear is not yet engaged with the driving gear. (Photo courtesy of Forrest Atkinson.)

1/8 Scale Knucklehead Kick Starter

When the kick starter lever is engaged, a spring pulls the rack gear down so it engages the driving ratchet gear (shown here) that is connected to the primary gear train. (Photo courtesy of Forrest Atkinson.)

1/8 Scale Knucklehead Kick Starter

As the kick starter moves through its travel to the end (shown here) it turns the motor over the same number of degrees as the original kick starter did. If the engine fires mid-stroke, the shape of the gears kicks the rack gear out of the way, avoiding an old Harley injury commonly know as “Sportster Knee.” That’s when the engine would kick back unexpectedly on the starting lever, and either toss the rider over the handlebars or injure their knee. In Jerry’s case, “Sportster Finger” will be avoided by Jerry’s design. He noted that the sound of the rack feeding back over the ratchet gear even mimics the actual sound of the real kick starter. Several weeks of work were needed just to get the shape of the teeth right between the rack and ratchet gears. That way it can engage firmly, but also kick out like it should.

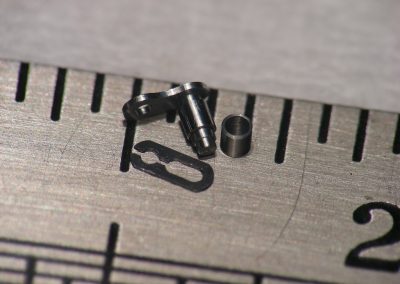

1/8 Scale Knucklehead Spoke

The tiny wheel spokes are perfect 1/8 scale replicas. They include a swedged end, and a threaded end. The spokes are .020” in diameter, and the thread is 190 tpi. The nipple threads onto the spoke for tightening and adjustment, as is practice on full-size wire wheels. They are not simply laced with wire, as is done on most model wire wheels. This image shows the nipple threaded onto the spoke.

1/8 Scale Knucklehead Spoke

Over 100 of these spokes must be produced, and then individually installed and tightened. In this photo, the nipple was removed to reveal the tiny threads. These photos were taken in February of 2009, and Jerry expected the wheels—including spokes, rims, valve stems, brakes, and bearings—to take about a year to complete.

1/8 Scale Knucklehead Wheel

In April, 2009 Jerry brought his nearly finished front wheel to display at the NAMES Expo. Notice the tiny valve stem.

1/8 Scale Knucklehead Wheel

The miniature wheel actually contains a working Schrader valve, and the brass valve cap has the correct number of knurls.

1/8 Scale Knucklehead Progress

The motorcycle’s front forks, handlebars, suspension, and headlight were also coming along at this point (April, 2009). The throttle cable was installed, and it really works when the throttle is twisted on the handlebars.

1/8 Scale Knucklehead Progress

A year later, Jerry completed the wheels (4/28/2010). This task included making over 100 miniature threaded spokes, and two working 3-piece Schrader valves for airing up the tiny rubber tires.

1/8 Scale Knucklehead Wheel

A close-up of the front wheel shows the drum brake, with brake cable affixed. The threaded nipples on each wheel spoke can also be seen, along with the bottom end of the “springer” front suspension.

1/8 Scale Knucklehead Spark Plug

More photos of Jerry’s progress on the scale motorcycle were taken at the NAMES Expo in April, 2011. Here, Jerry holds one of the tiny scale spark plugs. It’s made in two pieces, just like the original.

1/8 Scale Knucklehead Motorcycle

The following photos show more details of Jerry’s progress on the scale Knucklehead.

Miniature Gear Cutting

This photo shows a setup that Jerry demonstrated at the NAMES Expo. Spectators could look through a microscope that Jerry attached to his Sherline mill, and see the tiny gear being pointed to in total detail. A tiny gear tooth cutter is behind Jerry’s finger, which cut the teeth for this mini distributor gear.

1/8 Scale Knucklehead Oil Bag

The miniature oil bag (tank) will go under the seat. Notice the tiny wing nuts.

1/8 Scale Knucklehead Motorcycle

In March, 2012 Jerry sent this and the following photo showing the Harley in an updated state of completion. The Schrader valves in the wheels were completed, and the tires were inflated to 4 psi. That is 1/8 of the inflation of the full-size bike. It yields just the right amount of flat spot on the tires when the tiny bike is resting on them.

1/8 Scale Knucklehead Motorcycle

The cables are in place, but some have not yet been connected. The seat pan was made, but had not yet been installed on the bike.

1/8 Scale Knucklehead Motorcycle

In April, 2012 Jerry brought the model motorcycle with him to the NAMES Expo in Wyandotte, MI. By this time, Jerry had added the seat, a working speedometer, and Schrader valves in the wheels. (Photo courtesy of Ken Foran.)

1/8 Scale Knucklehead Motorcycle

The copper seat pan was formed, and is now ready for a leather cover.

1/8 Scale Knucklehead Motorcycle

The topside of the miniature Knucklehead engine with an open spark plug hole.

1/8 Scale Knucklehead Motorcycle

The right side of the engine has the characteristic knuckle-shaped rocker box covers, and the brass oil tank. This side also shows the kick starter pedal, carburetor, and brake lever

1/8 Scale Knucklehead Motorcycle

A close-up of the tire, wheel, brake, and fender. The gray metal is bead blasted steel.

1/8 Scale Knucklehead Motorcycle

Jerry was covering the steel with a coat of oil to keep rust from forming until final painting.

1/8 Scale Knucklehead Drive Chain

Jerry’s original intention was to stamp the sides of each drive chain line. However, the quality of the stampings wasn’t up to his standard, so he ended up machining each one.

1/8 Scale Knucklehead Drive Chain

For size reference of one linkage, the lines on the scale are .011” wide.

1/8 Scale Knucklehead Drive Chain

The chain is installed on the bike with the primary cover removed. Jerry noted, “The chain itself has 440 separate parts that needed to be machined, including the master link. I made dies for stamping the side plates or links, but the quality of the stamping and the amount of finish work required for the quality desired was prohibitive when considering the final result. In addition, another 220 separate bearing pin rivets were required for assembly of the chain.” (12/3/2013).

1/8 Scale Knucklehead Motorcycle

A close-up shows the brake lever, gas cap, and gated shift lever on the left side of the tank. The working speedometer will go in the hole on top of the tank.

1/8 Scale Knucklehead Key and Cylinder Lock

The tiny scale model ignition lock cylinder and keys. Inside the cylinder, tiny coils of .001” diameter wire push on the pin tumblers. (3/2/2016).

1/8 Scale Knucklehead Motorcycle

The remarkable scale model motorcycle is nearly complete. The decision now is to paint it, or leave it in raw metal. (3/2/2016)

Knucklehead Speedometer and Air Cleaner

Jerry’s scale Knucklehead has a working speedometer that’s about 1/2” in diameter. Jerry submitted a video of the speedometer in action. The short video shows Jerry spinning the speedometer shaft to get the needle to move. He noted that, like the full-size speedo, the needle bounces around a bit in the lower speed ranges. However, it smooths out as the speed tops out at about 40-50 mph. Just getting the tiny magnets properly placed in this little gem took several months of adjustment. The work was worth it though, because one of Jerry’s main goals for this project was to have a functioning speedometer—along with a kick starter, working brakes, transmission, and pressurized tires.

The functional 1/8 scale Speedometer for the Knucklehead. This tiny working mechanism is smaller than Jerry’s thumb.

The photo below shows two scale air cleaners for Jerry’s Knucklehead motorcycle. The 1/8 scale Harley-Davidson air cleaner on the right was made by Jerry. He sent it to master engraver Roger Ronnie to have him engrave the logo at 1/8 scale. As a practical joke, Roger made a replica air cleaner of his own (on the left), and gave it to Jerry. Upon closer inspection, Jerry could see that the tiny letters under the logo read, “Made in China.” After Jerry recovered from the surprise, Roger presented him with his actual air cleaner with the original engraving: “Made in the USA.” Roger’s version of the tiny air cleaner is on display in the Craftsmanship Museum, while the correct one has been fitted to the engine.

Return to Jerry Kieffer’s main page.

This section is sponsored by:

Makers of precision miniature machine tools and accessories. Sherline tools are made in the USA.

Sherline is proud to confirm that Jerry Kieffer uses Sherline tools in the production of his small projects.