Complex 3D Puzzle Sculptures Machined From Metal

A Lifelong Passion Turns Into a Second Career

GarE (pronounced Gary) Maxton was born in 1954. During high school in Ann Arbor, Michigan, he took a few summer school art courses where he learned welding. Subsequently, GarE purchased his first welding setup and built a shop in his parent’s garage. He sold his first large art piece, Automation I in 1974. At the time, GarE was displaying some work simultaneously at the Ann Arbor Street Art Fair and the University of Michigan Artists and Artisans Guild Fair.

GarE graduated from Western Michigan University Summa Cum Laude with a Bachelor of Science degree in 1977. GarE’s real estate business, Maxton Ltd. was incorporated in January, 1981. Business was good, and he was able to retire in 2000 at the age of 46. GarE purchased a micro-mill that same year, and started learning how to machine.

He started his own website in 2002 to display and sell his unique puzzle sculptures. Since then, GarE’s second career has been making and selling his machined metal puzzles.

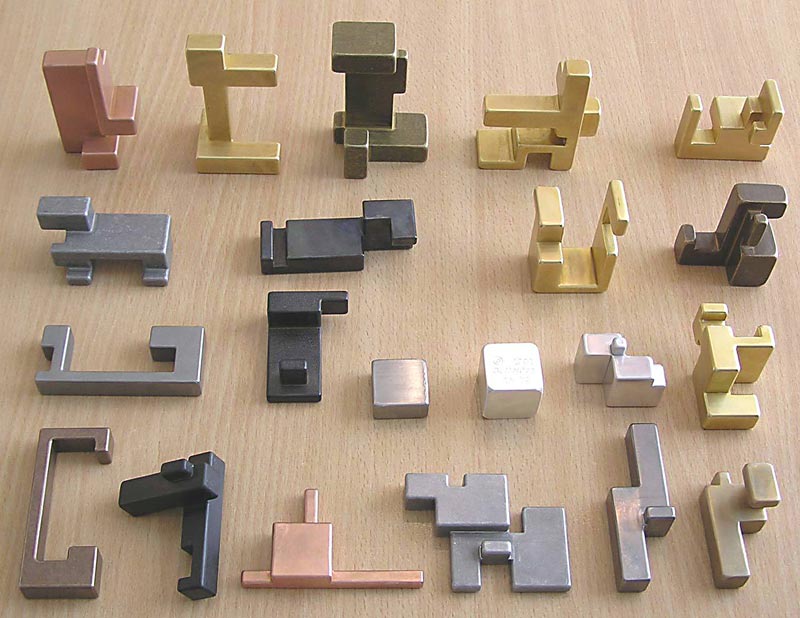

Conundrum II is a challenging 21-piece puzzle sculpture. It is composed of pieces made from aluminum bronze, cast iron, copper, aluminum, titanium, bearing bronze, stainless steel, steel, tungsten, silver or gold, magnesium, and brass.

Now, these are no ordinary puzzles. GarE’s creations are very complicated 3-dimensional metal works of art. Each piece must fit with precision and also look attractive when assembled. It takes an unusual set of talents to be able to conceive, design, produce, finish, and assemble the many precision pieces that make up these puzzles.

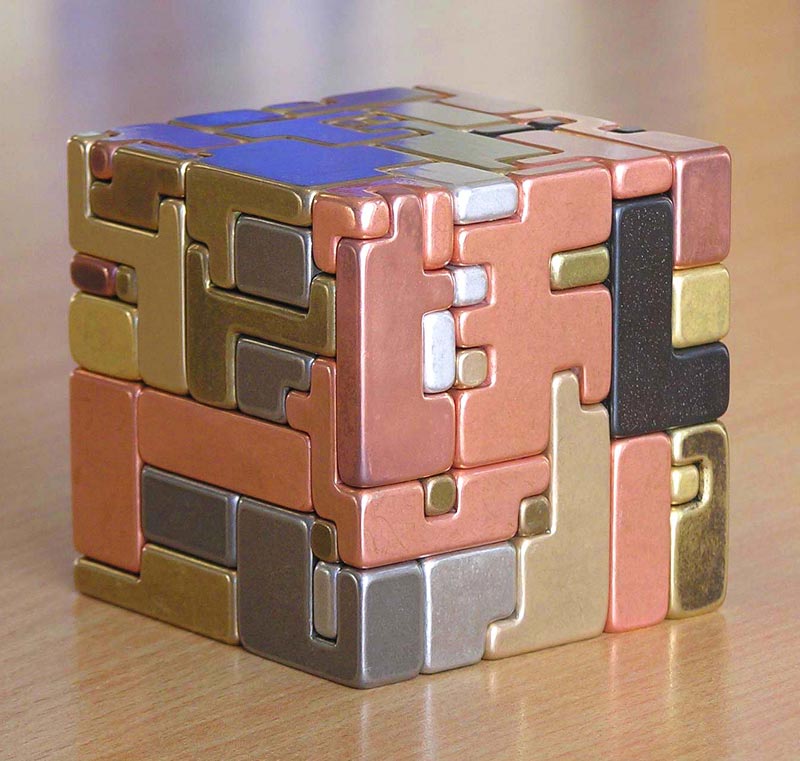

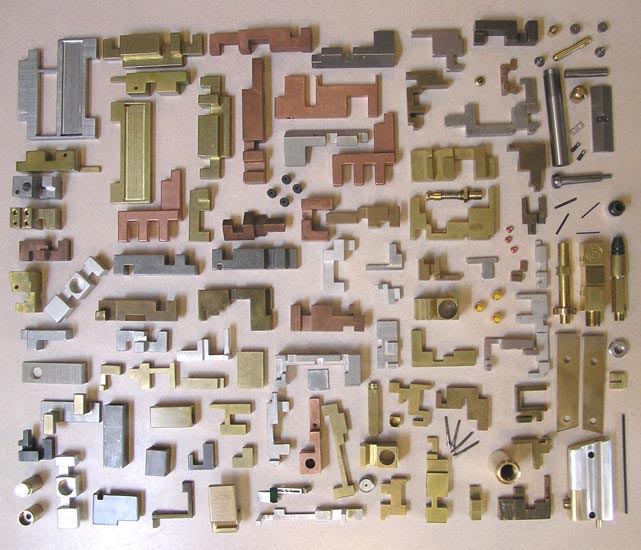

GarE’s puzzle called Conundrum III, for example, is a 3-inch cube when assembled, and consists of 54 individual pieces made from 20 different metals! Since the setup for machining each piece is intensive (in other words, expensive), it is not practical to make just one. So, GarE typically does a limited production run of ten or more sculptures, which are then offered for sale to art and puzzle aficionados around the world.

The metals used in Mr. Maxton’s sculptures range from common to exotic to precious. They include: brass, aluminum, cast iron, neodymium iron, stainless steel, steel, magnesium, titanium, copper, pewter, tin, zinc, aluminum bronze, white brass (Babbitt metal), bearing bronze, silicon bronze, Monel, tungsten, Inconel (a very difficult to machine space-age metal used in jet engines), silver bullion, 24K gold, various forms of Mokume Gane, and on one occasion even Damascus steel. The following is Mr. Maxton’s description of the process he uses to make his limited edition puzzles.

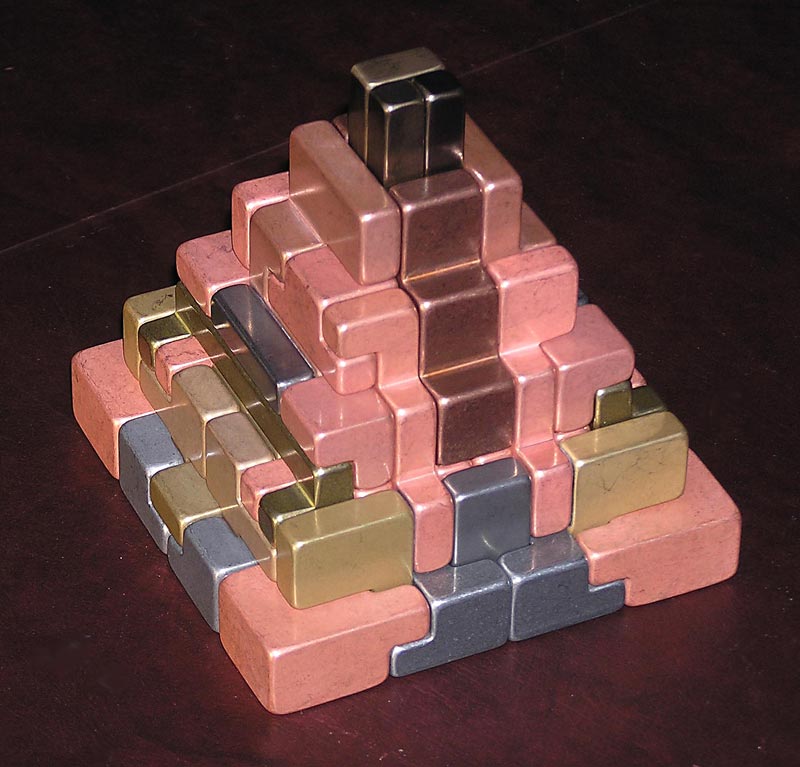

This 54-piece puzzle called Conundrum III is about 3” on each side, and was made for the serious puzzle solver. How would you even begin to take it apart, let alone putting it back together? The individual pieces, made of various types of metal, were not painted—although some can have a patina applied.

The Making of Conundrum III

By GarE Maxton

Creating metal sculptures with interlocking pieces involves a multi-step process. Although this precision work is very time consuming, it would be astronomically priced without current CNC milling technology.

The first step is to create a rough model. Creating one out of metal on a prototyping mill can take me up to a year per sculpture, so other materials are often substituted to expedite the task. I generally work hands-on until I create something that pleases me. I don’t derive any satisfaction from designing sculptures on a computer, so I rarely use them for this purpose.

I make a fully functional, finished puzzle sculpture in my prototype shop. This can take several months. It involves taking each piece of the rough model and writing a CNC program to cut that part from one of numerous metals. All the parts closely match the rough model I have already created; any mistakes that may have been overlooked in the design of the model are fixed at this point.

The next step is to draw each piece of the sculpture in .STL file format. (An .STL file is a stereo lithography format used for doing 3D drawings in a 3D CAD program.)

The purpose of this step is to create working drawings so I can have the rough pieces quoted, and subsequently made by a third party in some volume. If I didn’t outsource this step, I could produce about 20 finished sculptures a year. Although outsourcing uses large, efficient equipment, the process is very expensive and generally accounts for an outlay of up to 50% of the retail price of any one of my sculptures. Outsourced CNC costs are too high for just one part at a time, so at a minimum I must run 10-20 of each part in any production run.

When the rough pieces come to me from outside sources they need to be finished. Any final cuts must be made on my CNC equipment. Then, all flat exterior surfaces must be carefully sanded to remove the extensive minor scratches from milling without altering the piece dimensions significantly.

The edges may be rounded or beveled to give the pieces a nice feel, and then the parts are fit together and further sanded where necessary until the fit is just right. For fully rounded sculptures, I use tumblers to aid the finishing process—especially if the pieces are severely scratched.

My final surface finishes are brushed, patina’d and occasionally polished. The patina’d surface by far offers a more stable finish, as it is less likely to tarnish or show scratches after handling. The mirror polished sculptures offer the most stunning color display. As a final step, the finished parts of each puzzle sculpture are waxed for protection, and then reassembled to confirm an excellent fit and appearance.

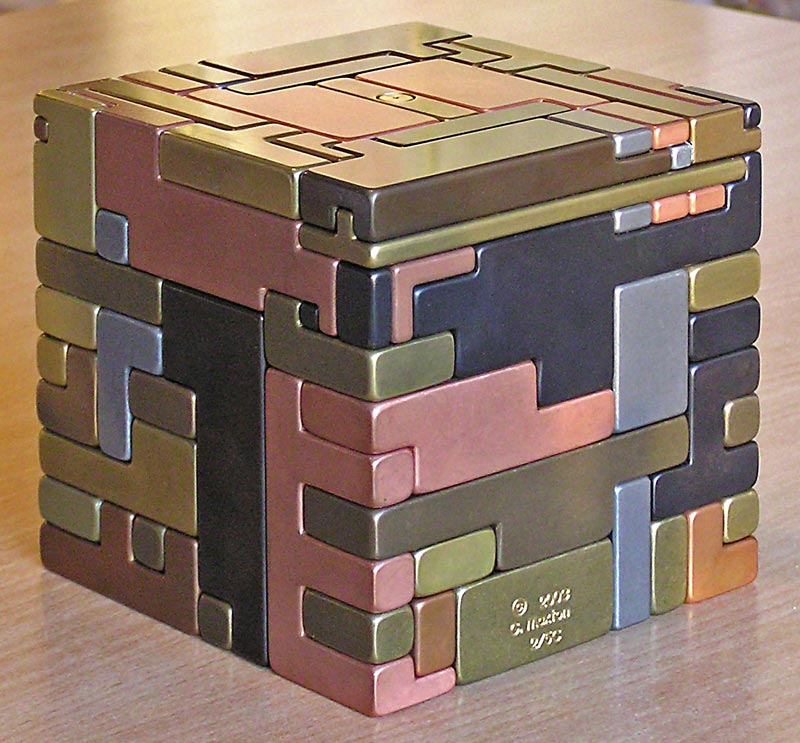

The Labyrinth puzzle is a provocative contemporary desktop sculpture designed after Mr. Maxton was introduced to the concept of a Japanese puzzle box. To open this colorful vault you must discover the special sequence of sliding metal panels at the top. Once the top is opened, the puzzle can be broken down into 42 separate metal pieces. This particular Labyrinth puzzle was built with a hidden pop-up handle.

I’m having a lot of fun making these geometric puzzles, so much so, in fact, that I’m reluctant to spend a lot of time away from my shop. You may have noticed I don’t set up exhibits in art fairs. Long ago, I remember sitting at the Ann Arbor Art Fair for a couple of 10-hour days… that was enough for me. This time around I only want to do the FUN part; that is, designing and producing the artwork. If you want to see more, you’ll have to peruse my detailed website or come and visit my shop. I enjoy direct marketing my work over the internet.

I get interesting emails from people all over the world, and have shipped sculptures as far as Europe, Asia and Australia. Before the internet age, I would never in a lifetime have been able to represent my work in such a wide marketplace. As the clarity of color monitors improves, these types of transactions will only get easier. By the time I retire for the second time, I expect to have contacts all over the world!

—GarE Maxton

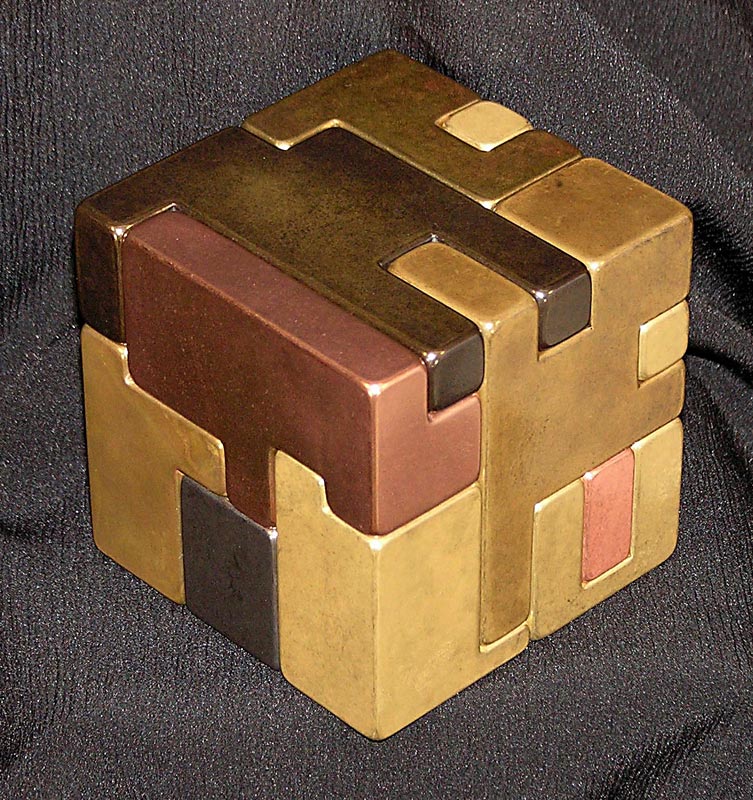

Symmetry I is a sleek, elegant coffee table sculpture. It’s composed of 20 aluminum and brass pieces, forming a contemporary 4” cube.

Mr. Maxton doesn’t just make cube puzzles. In Pyramid I, one of the puzzle pieces is also a secret key for the optional 1.5” miniature central vault. The sculpture is composed of six different metals in 17 different shapes. For added coloration and complexity, some of the pieces are composed of two different metals, which are dowel-pinned permanently together.

An Update From GarE—Making The Intimidator

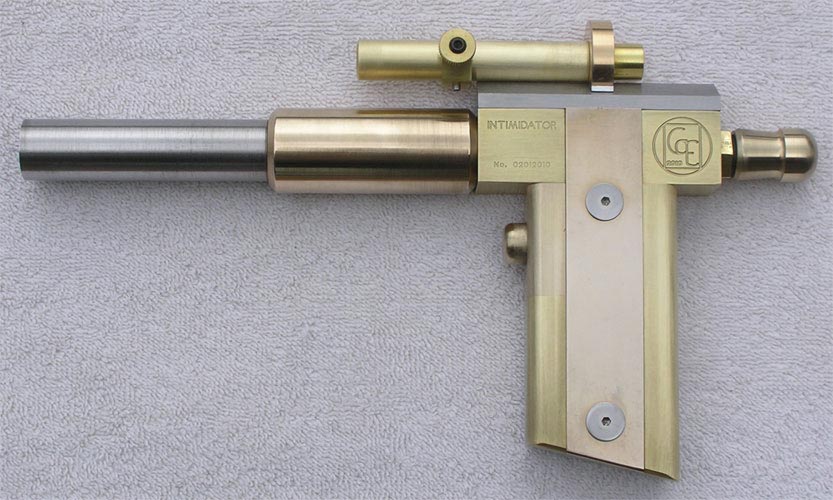

GarE has done complex work (Conundrum III), religious puzzles (Cross), work with precious metals (gold and silver), and now “intimidating” puzzles with his most recent work—The Intimidator. GarE noted, “This design is by far my most complex metal sculpture, and it’s both mentally and physically intimidating—thus the name. For those challenged by Micro-Conundrum, I suggest giving this sculpture a wide berth. This design expands the limits of what is considered possible for a puzzle; it’s a puzzle with an intimidating function.”

Mr. Maxton added, “In June 2009, starting with a few extra parts from my Labyrinth sculpture, I began working night and day creating this sculpture. It grew to eight inches tall, four inches deep, and five inches wide. There’s a lot of volume to fill with interlocking parts, and assembly of this puzzle is extremely difficult—you’ll need a lot of time on your hands. Physically, it tips the scale at over 40 pounds.”

GarE added an incredible twist to this 125-piece puzzle. Hidden inside are all the parts needed to assemble a firing .45 caliber muzzle loading pistol! (A Federal firearms stamp was obtained for the prototype, and will be supplied with each puzzle purchased.) If the puzzle itself wasn’t intimidating enough, the pistol and ammunition hidden within certainly give further credence to the name.

The pistol with laser sight was inspired by the James Bond movie, The Man With the Golden Gun. Watch GarE’s video of the disassembly of this massive puzzle, plus a firing of the hidden pistol. More details and video are available on GarE Maxton’s website. Like many of his other models, The Intimidator was made as a very limited edition offering.

View more photos of Mr. Maxton’s intricate metal puzzles.