Below you can view more photos of Damien Connolly’s impressive work. Click on images to enlarge.

Knife Making and Engraving

Connolly Knife

Crafted in the late 80’s, these 24k. gold inlaid and relief carved eagles were directly inspired by U.S. wildlife artist Guy Coheleach.

Connolly Knife

A Connolly designed and made knife, engraved with a large foliate motif. Take note of the carefully filed and polished edges and planes.

Connolly Knife

This knife has 24k. gold inlaid and relief carved bighorn rams. It was designed with the input of the client, and features bighorn rams horn as the handle, or scale, material.

Premium Gun Engraving, Embellishment, and Display

Colt Revolver Handgrip Carving

These next seven photos illustrate steps in the process of carving a deep relief handgrip for Damien’s special Colt Revolver display case project. The design concept was drafted on paper before being developed on the white painted walnut grips.

Colt Revolver Handgrip Carving

The design is scribed over the inked lines. This prevents any loss during the 80 odd hours of handling before background removal is complete.

Colt Revolver Handgrip Carving

The design outline is plunge cut, with chisels as fine as 0.2mm (0.8mm in use in picture). Then the background is chipped and flicked out before being scraped smooth.

Colt Revolver Handgrip Carving

The design is chiseled, scraped and burnished to completion one small section at a time.

Colt Revolver Handgrip Carving

The progression of checkering at 50 lines-per-inch through the design.

Finished Colt Revolver Handgrip

In this shot the grip panels are still separate, and not tightened to the frame of the pistol.

Winchester Rifle

A .375 Holland and Holland Model 70 Winchester rifle, built and engraved for US firearms author and historian R.L. Wilson. Pictured in three of Wilson’s books, it features a quick detachable scope mount with slip-on caps to conceal the tapered dovetails when the scope is removed.

Winchester Rifle

The caps are stowed in a recess in the pistol grip, under the engraved oval cap that swings out on an articulated hinge.

Winchester Floorplate Carving

An African Cape Buffalo carved from steel in relief adorns the magazine floorplate of a .458 Winchester rifle. The background scene is executed in Bulino—tiny dots cut into the polished steel background with the graver.

Gazelle Engraving

Perhaps the most demanding of engraving disciplines, this is a frieze-like motif of a cheetah running down a group of Thomson’s gazelles. It has been cut from the steel in high relief to leave a polished background, devoid of tool marks or ripples. Many hours of great care with scrapers, stones and laps are required to achieve this effect.

Colt Army Percussion Revolver

Though functionally excellent, and with a good bore, this Colt 1860 Army percussion revolver was in badly rusted condition. Damien restored the flat planes, and trued the surfaces to the highest standard. Then he engraved it with a rich motif of Victorian scroll.

Colt Army Percussion Revolver

New screws were made throughout, along with several other parts, and a new set of select walnut grips.

Gold and Walnut Makeup Jar

This 18k. gold and walnut makeup jar has fine gold lines inlaid to the lid. They measure just .005” across. The gold was rolled to .002” thick before being inlaid to a depth of .020”-.025”. The process of polishing the gold flush results in a microscopic burring of the edge, which increases the width of the line. The rings were also made by Damien.

Colt Revolver Case Lid Inlay Series

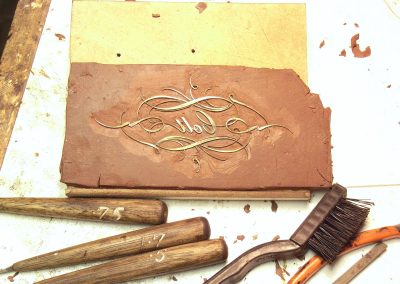

Grinding Strips

Guillotined strips are ground and filed to a predetermined series of waists and humps, before being curled by hand to match the drawn design. All design elements have a small amount of draught (a vertical taper) to the edges to facilitate a neat inletting job.

Peeling the Paper Layer

With the superglue softened by acetone, the paper is peeled away from the embedded design.

Pouring the Plaster

Dental plaster is poured over the design. When fully set up, the clay is removed, and all joints are excavated of plaster. Then they’re cleaned thoroughly before being silver soldered. The soldered junctions are then filed clean and true.

Applying the Lacquer

Inlay area is given a light coat of flat black lacquer. The design is pre-formed to match the dome of the lid. Then it’s super glued in place to allow the scribing of outlines that will show clearly on the blackened surface.

Plunge Cutting

Excess wood is plunge cut to the scribe lines, and flicked out with chisels sharpened to a stronger angle.

Testing the Cuts

The design is carefully tried in the cuts. Its fragility mandates first cut accuracy, as a tight fit will cause damage on removal of design.

Setting the Inlay

When all is right, the design is tapped into place with glue to about .060”. Then the process of filing down to wood level begins. The inlay is filed flush, and the feather edges left by the file are trimmed using a specially shaped graver.

Polishing the Case

Polishing is followed by shading the intersections of lines with the graver. After the grain of the wood is raised, and the pores completely filled, the whole case is given a dozen coats of acrylic lacquer. Then it’s cut back with 1200 grit paper, before finally being polished with rottenstone and oil.

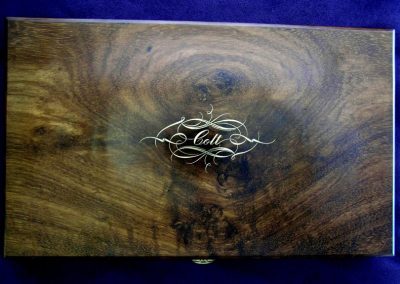

Colt Case Lid

The Colt case lid “push to open” catch. The mechanism is attached to the central ribbon motif, and is installed from the front. The surrounding tendrils are inlaid in the same way as the Colt motif.

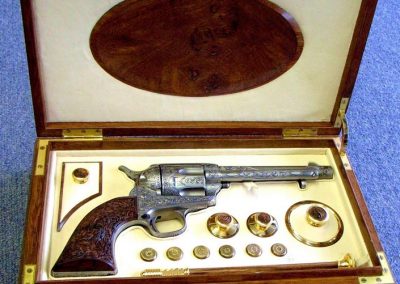

The Completed Ensemble

Manufactured in 1878 in New Haven, CT, Damien restored and engraved this model 1873 Colt single action Army pistol. It features carved walnut grips and a bespoke case. All hinges, screws, accessories and other hardware are custom made by Damien Connolly. This is the result of over 1100 hours of labor.

Project Planning—A Painting in Gouache, Pastel, and Pencil for a Unique Rifle

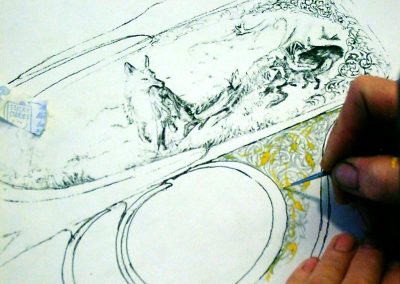

Breakfast Scene in Pencil and Gouache

The foxes will be in gold relief, with the rest of the scene varying from relief to Bulino. Bulino is a technique where the images are composed of thousands of tiny dots pricked into the polished surface with the point of a graver.

Woodwork Details

The woodwork is depicted in many layers of pastel over a foundation of gouache. Each layer is fixed with a matte artists fixative. Each checkering diamond has all four facets individually painted to represent the wood’s color at that facet’s angle to the light.

Inlay Details

This is one complex inlay/carving design, but has proven to be eminently achievable with the right approach.

Completed Rifle

Designed for cartridges with a head size of .222 Remington or smaller, this is one petite rifle. The overall style and proportion give it the feel of a scaled down express rifle. A great deal of care has been taken to achieve a balance between the visual weight of the metal components, and the woodwork. The receiver is just over 2/3 the height of the popular Ruger No. 1.

Damien at Work

Damien working to blend function and aesthetic on the wood and polyester filler mockup. The mockup enables accurate planning for the way metal meets wood—and hence the engraving design.

Modeling in Clay

The rifle that Damien did this work for has the following specs: Single shot falling block action, a unique and elegantly simple design engineered by Damien. Barrel length as depicted is 24-1/2”. Length of pull is 14-1/4”. Projected weight was 6.2 pounds—plus scope and custom detachable mounts. There are no visible screws. All barrel furniture (sights, rib, swivel bases) were machined integral from blank.

1/5 Scale Miniature Kentucky Long Rifle

This tiny project involved approximately 2000 hours of work, and it was not done on commission. Damien simply wanted the challenge of working this small, and it serves as a fine showcase for his skills as a gunsmith and engraver. The following photos and captions briefly explain its construction. Additionally, Damien has provided a more detailed article on the subject. Many of the photos from the article are reproduced here.

Rough Finished Set Trigger Group

The rough finished set trigger group and main spring securing screw, which is only 0.8 mm. The trigger adjusting screw is 0.4 mm. Damien produced his own dies to make all the tiny screws on the rifle.

Various Components

The roughed out barrel tenon blanks, and star shaped escutcheons, with the rifle assembled to dummy “mule” stock. Adding or removing the thickness of a couple of pieces of paper to a dimension can change the whole look of parts at this scale. The trial stock was begun merely to ensure the fit, curvature, and relative scale of the various parts. But it rapidly evolved into a valuable test bed for achieving the look of a classic Lancaster School long rifle. Note the parts merely embedded in filler, the saw cuts, and the pieces added to allow reshaping. Damien said that he worships at the altar of epoxy filler and superglue!

The Lock Internals

Overall length is 23 mm. The flint is sculpted and heat blued stainless steel, held in thinned pigskin lining material from case. Just visible through the lower aperture in the bridle is the fly—or detent. This ensures the sear nose does not catch in the half cock notch when the set trigger is used.

The Sideplate

The sideplate is pierced and carved from a .032″ piece of 316 stainless steel, using traditional engraver hand tools only. The final finish is achieved using a variety of ebony, cast iron, and steel laps charged with abrasive paste. This piece is under an inch long, and is inlaid into the wood about .020”. The fit is all wood to metal—no filler.

Stock Details

Of note in this picture is the extremely fine natural striping, or fiddleback, in the curly maple stock. Also, the delicately filed fences where the tang transitions onto the barrel, and the .012″ diameter pins through the stock that retain the trigger guard in the traditional manner.

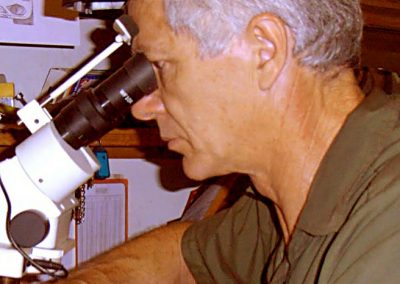

Damien Using the Microscope

Aside from the important part it plays in reducing eyestrain, only through the use of a microscope can the fit and finish of parts, and the precision of engraving at such a small scale be maintained.

Barrel Details

The barrel is just over 9″ long, has a bore of .098”, and is rifled with 7 individually broached grooves.

Kentucky Long Rifle

These next pictures give an idea of the diminutive size of this tiny masterpiece.

Kentucky Long Rifle

Excluding only the length of the rifle and the width of the butt, no dimension comes close to the width of one of Damien’s fingers.

Miniature Kentucky Rifle Case

In addition to the many uncounted hours of planning and drawing, Damien spent 396 hours constructing this display case for the miniature Kentucky rifle. Using the same timber as was used for the stock, the case consists of a mitered frame. It has a top panel carved and scraped into its violin back shape at a thickness of .080″. The pigskin suede lining material was ground to .020″ thickness, before being stretched and glued over the precisely carved block that forms the case interior.

Rifle in Custom Case

As with the rifle, Damien made all the wood screws used in the case. He also made the hinges, which feature an opening and closing detent to add to the effect of premium quality work. The cleaning rod rotates in bushes in its handle. It also features a removable jag that can be replaced with a wool mop stored in the top left compartment.

Rifle in Custom Case

The Connolly name is attached to the lining of the lid, in 24k. gold lettering. Each one of these letters was formed, or coined, in an individual die cut.