The Seal Engine Project

Building a Seal 15cc Internal Combustion Engine

A Group Project With Parts Made by Model Engineers Around the World

The project featured on this page was built over the course of a year in the Craftsmanship Museum machine shop. Many of the parts for this engine were built by different craftsmen from around the world, and then assembled in the Craftsmanship Museum. We have documented the build on this page, and recognized the craftsmen who contributed. Many photos and descriptions of the process have been provided as a teaching experience.

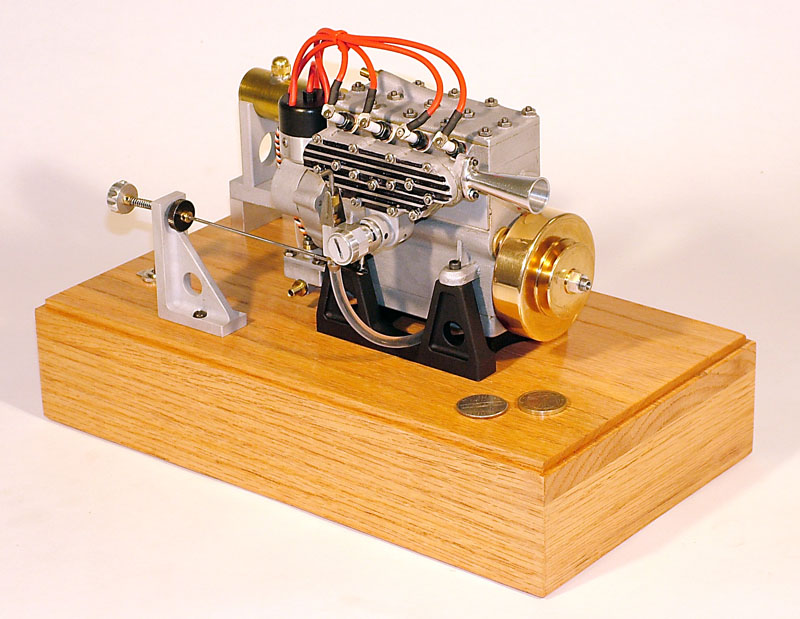

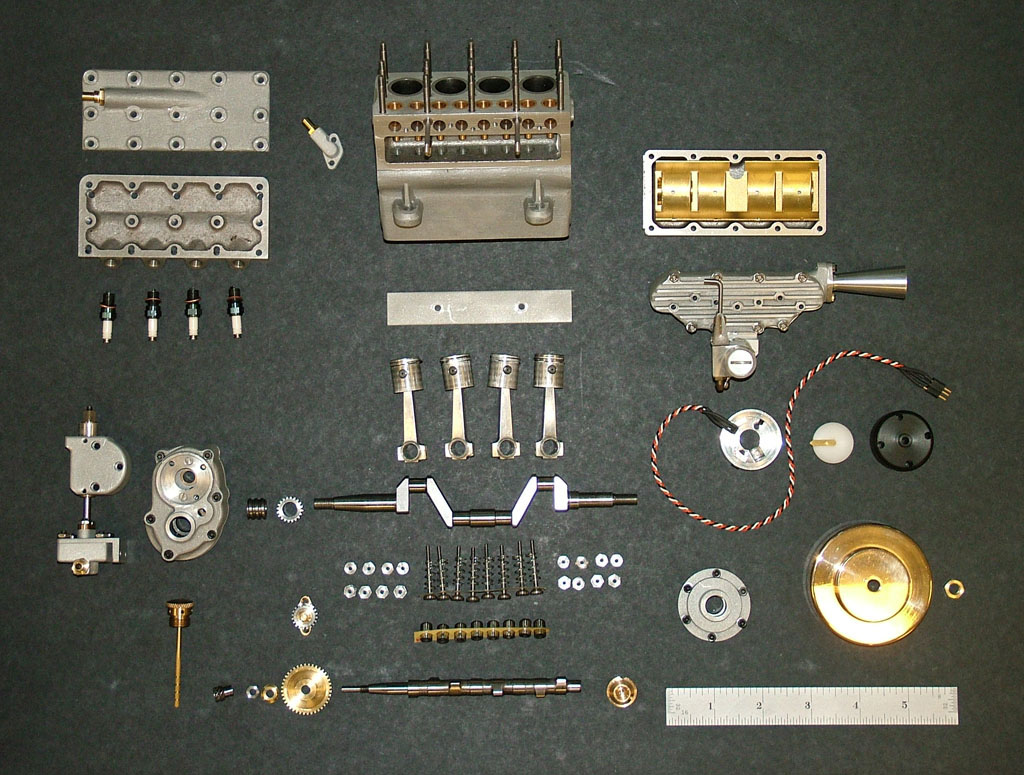

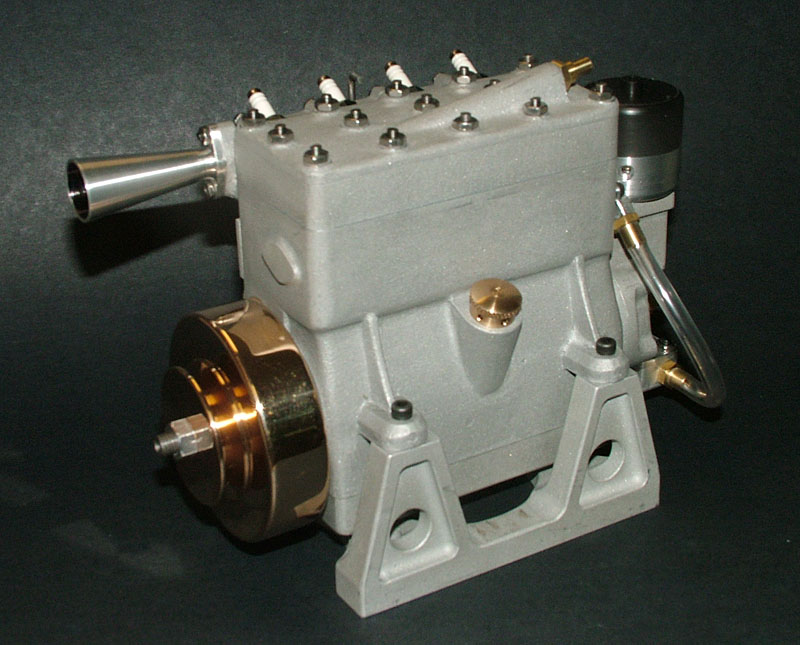

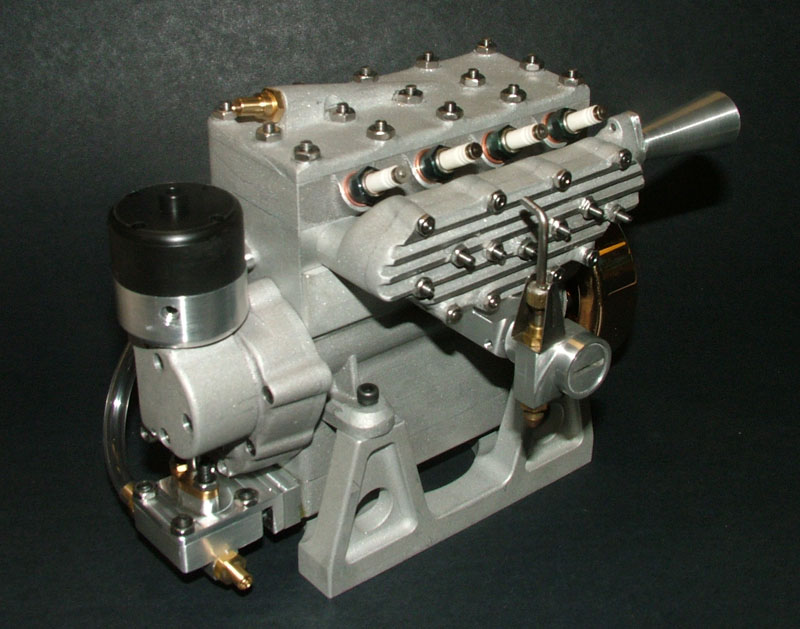

Shown here is the unmachined casting set for a Seal 15cc IC engine. The photo shows a finished Seal engine on the cover of the September, 1954 issue of The Model Engineer magazine. Initially, Joe Martin had started the project years before, having made the crankshaft and connecting rods. The Craftsmanship Museum enlisted the help of many other model engineers to finish this engine, which is now proudly on display.

Starting the Seal Engine Project

The Joe Martin Foundation began the construction of a 15 cc, 4-cylinder internal combustion engine in July, 2006. The goal was to make this running Seal engine for eventual display as part of the Craftsmanship Museum’s collection in Carlsbad, CA. We started out with a casting kit and a set of plans, and began to enlist the help of others.

Tom Boyer ran the museum shop, and acted as both machinist and job coordinator for the project. We invited model engineers from around the world to participate in the museum shop project. A list of those craftsmen, along with their contributions can be found below (*check).

Engine Specifications

- Designer: Edgar T. Westbury (designed in 1947)

-

Type: 4-cycle, water cooled, inline 4-cylinder

-

Size: 6.75″ L x 4.75″ W x 5.25″ H

-

Displacement: .84 cu. in. (13.8 cc)

-

Bore: 5/8″

-

Stroke: 11/16″

- Carburetor: M&H Variable Venturi (modified)

-

Ignition: ProSpark electronic with Hall sensors and rare earth magnets, Rimfire long reach spark plugs

-

Fuel: white gas

-

Started: July 25, 2006

-

First Run: July 21, 2007

Additionally, view a copy of the specifications with a photo of our finished Seal engine.

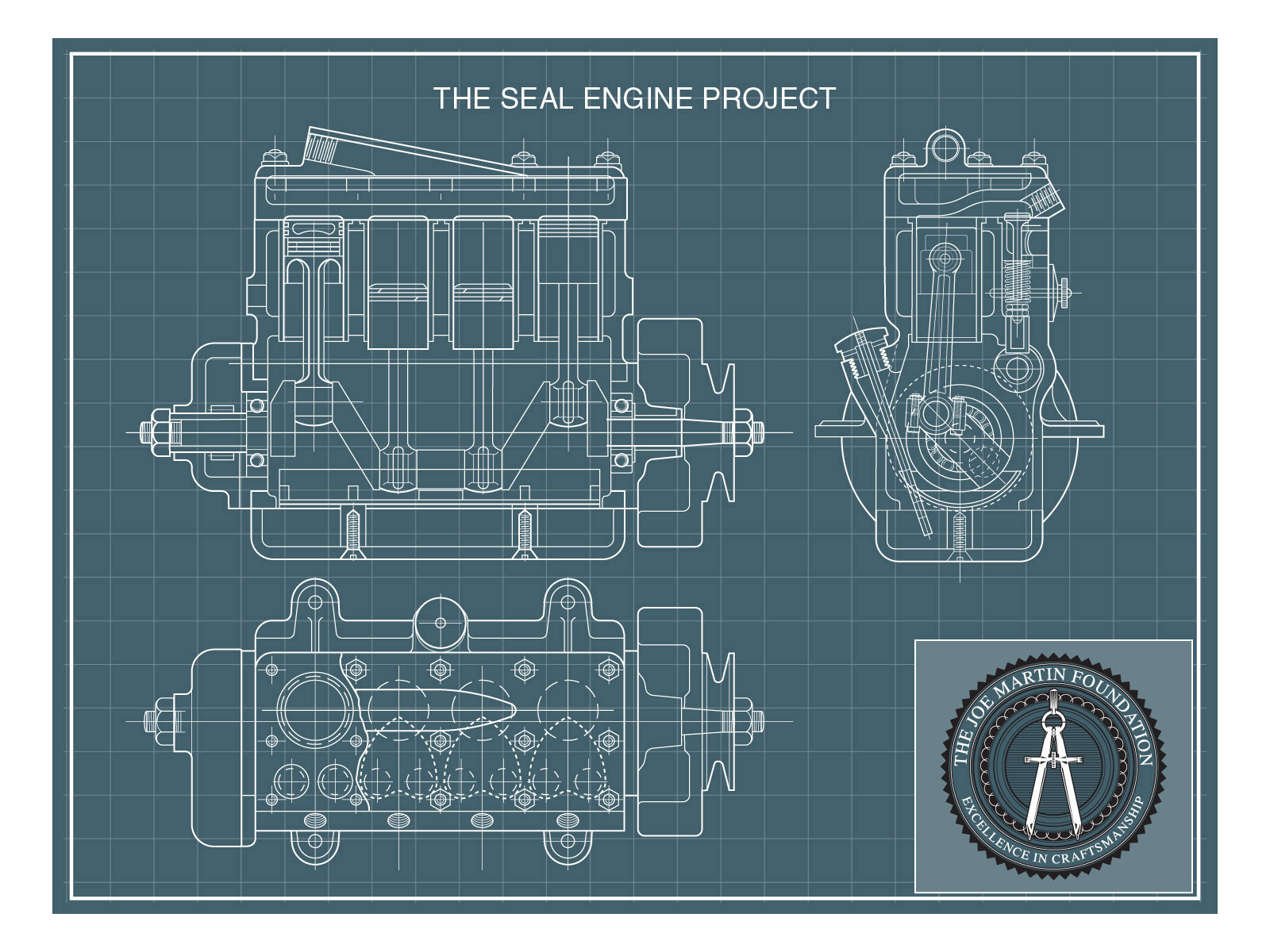

Charlie Tomalesky, a talented industrial designer, volunteered his skills to convert the hand drawn 1940’s Seal plans into electronic form. He was able to make 3D CAD drawings of all the parts and assemblies. This photo shows the 3-view drawing, and a logo medallion that Charlie came up with for the foundation. Charlie is obviously highly skilled, and more of his CAD drawings can be found below.

The Build Team

View a list of the build team members for the Seal engine project, along with some of the components built by each craftsman.

Additionally, view a copy of our build team plaque, produced by Craig Libuse.

Model Engineer Articles on the Seal Engine

Model Engineer magazine in England published a 13-part article by Edgar T. Westbury (the engine designer) on the Seal engine—starting with the February 9, 1947 issue. Because of copyright issues, we cannot republish those articles here. However, the Craftsmanship Museum now owns a complete collection of Model Engineer magazine issues going back to the first publication in 1898. In our library, visitors have access to these issues, and are allowed to copy a portion of any issue for their own personal use.

We do not have a complete article index, but visitors are free to browse through our extensive collection. It’s often the case that the plans published in Model Engineer are actually more complete than the original plans. Additionally, the comments from the builder can very helpful in finding and fixing problem areas before you get to them. For example, we learned from the Westbury article that the firing order for the Seal as published in the plans was actually incorrect.

By May 10, 2007, the engine was nearly completed. It just needed the working parts of the distributor and spark plug leads. Joe Martin was also considering whether to replace the water pump with an oil pump.

Full Seal Engine Build

View our chronological documentation of the full Seal engine build, including many more photos and video of the running Seal engine.