World Famous Structures Built Entirely From Matchsticks

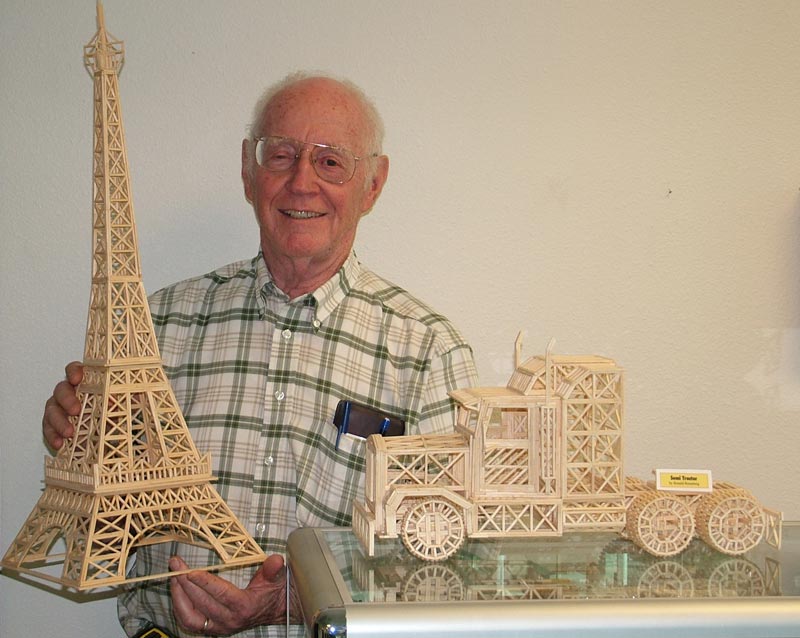

Ronald Remsberg displays two of his matchstick models—the Eiffel Tower and a semi truck. We thank Ron for donating nine of his matchstick models to the Miniature Engineering Craftsmanship Museum for display.

From Aerospace Engineering to Matchstick Modeling

Ronald Remsberg was trained as an aerospace engineer, and worked in the industry for 10 years before eventually switching careers. He started out with Convair in San Diego in 1960. Then, Ron moved over to the General Dynamics division of the company, where he worked until 1970. Initially, Ron worked on the F-102 Fighter with Convair. Later, he worked as a research engineer on various projects, including one called “BAMBI,” which stood for Balistic Anti-Missile Boost Intercept. BAMBI was a program to shoot down Russian ballistic missiles by means of defensive missiles stationed on orbiting satellites.

Unfortunately, most of Ron’s involvement was conceptual work, and he rarely, if ever, saw any concrete results from his daily labor. Many projects never made it off the drawing board—or even to the drawing board for that matter. For that reason, Ron liked to build things in his spare time. It was satisfying to watch a project go all the way from start to completion.

By 1970, the boredom finally got to Ron, so he decided to quit his job as an engineer and strike out on his own. From 1970—1978, he worked in the insurance industry, and then later sold products for Pitney-Bowers and a business forms company. Eventually, Ron found that sales, like engineering, was not what he wanted to do. Ron wanted to get into a business that actually made a product.

Around 1980, he got into the printing business, and founded Royal Instant Printing in San Marcos, CA. Within a few years, Ron realized that the wholesale business card market was a lucrative one. His company soon went from 2-3 employees to over 40. In 2006, Ron finally retired, and turned the business over to his children.

Big Ben is actually the name of a single bell in the clock tower at the Palace of Westminster in London, England; although, the entire tower is commonly referred to as such. Ron’s matchstick model is 23-1/2” tall, and has a 5-3/4 square inch base. Set in motion on May 31, 1859, the original clock tower celebrated its 150th anniversary in 2009.

Perhaps the most recognizable landmark in Paris, France, the Eiffel Tower was built as an entrance to the Paris World’s Fair. It is 1,063’ (324 m) tall, and the tallest structure in Paris. In fact, it was the tallest structure in the world until 1930, when the Chrysler Building was completed in New York. Ron’s matchstick model is 28” tall, and has a 10-3/4 square inch base.

Early Model Airplanes Provide a Foundation for Woodworking

Early in his youth, Ron became fascinated with flying models. Over the years, he built many free-flight, gas powered model airplanes. Ron liked working with balsa wood, tissue, model airplane cement, and the “dope” used to stiffen the paper and silk wing coverings. However, the glue companies soon changed their formula to offer a less toxic product, which also reduced the effectiveness for model making. Ron just never liked how the new glues or paints worked, and his interest in the hobby eventually faded.

A Challenging Start With Matchsticks—Building the Taj Mahal

At some point, which Ron can’t quite recall, he became interested in making models from matchsticks. It gave him the same satisfaction as building model airplanes, took up less working space, and used only simple materials and Elmer’s glue. Ron found a company in Canada that supplied matchsticks wholesale, and was able to purchase raw sticks (no match heads) in quantities of 2000 per bag.

Ron was also able to find plans for matchstick models, and his first project was an ambitious one—the Taj Mahal. Since then, Ron has built over a dozen such structures. Unlike his engineering and sales jobs, building wooden models gave Ron the satisfaction of seeing each session through to its ultimate end—a finished model.

Ron’s first matchstick project wasn’t a simple one. His miniature Taj Mahal measures about 16″ tall, and 24 square inches around the base. In his research, Ron had seen some very large structures built from matchsticks. He decided that if others could build those, he could build this much smaller model.

Now, most of Ron’s matchstick projects took about 3 months to complete. He worked for a few hours every night, and since Ron didn’t care much for television, this was a perfect arrangement. He noted that any time he worked more than about 2 hours at a time, he would start making mistakes. So, Ron never got carried away putting in long hours during any single session.

Even after sustaining an injury that caused him to lose sight in his right eye, Ron is still able to cut and glue thousands of pieces to build these complicated structures. Because he builds solely for his own enjoyment, time is no factor, and any given project takes, “as long as it takes.”

This 102-story landmark sits at the corner of 5th Avenue and West 34th Street in New York City. The Empire State Building stands at 1,250′ (381 m) tall, and was the tallest building in the world from 1931-1972. Ron’s model is 17” tall, and has a 3” x 5” base.

Working With Matchsticks

When Ron receives his bags of matchsticks, many are not very straight. Like a clarinet or sax player culling through reeds to find the good ones, Ron will go through thousands of sticks to remove the curved ones. (As the sticks have not yet been made into matches, he doesn’t need to spend time cutting off heads.)

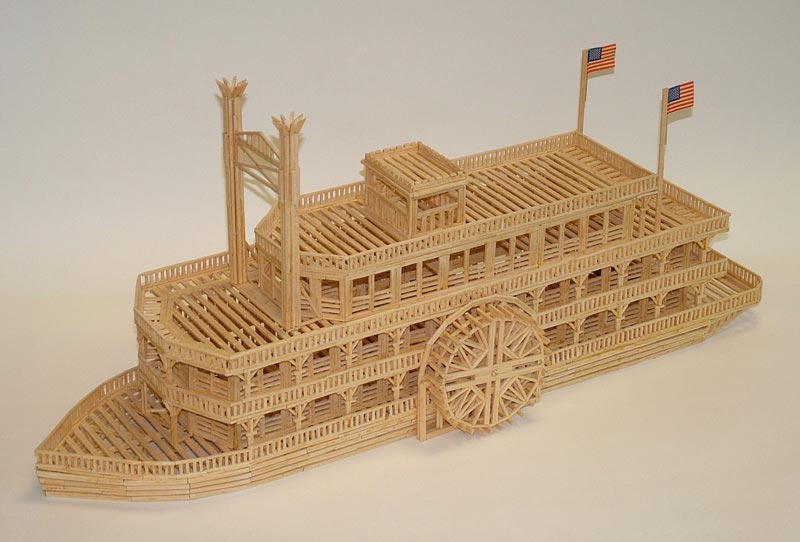

On his models, long structural portions are all made of shorter matchsticks glued end-to-end, so they must be straight. For strength, several lengths of sticks are glued side-by-side with overlapping joints. Despite what it may look like, no long individual pieces of wood are used. Everything was built up from these standard, short matchsticks.

Many of the parts that Ron built have a large number of identically sized cross-pieces. He actually designed and built his own cutoff tool for the work. That tool, with the help of an adjustable fixture designed by Ron’s friend, Paul Elsmore, allows him to quickly cut pieces at identical length using a razor blade.

Additionally, the Joe Martin Foundation was able to provide Ron with a compact adjustable cutter designed by Ralph Cooney of Fourmost Products.

Like the original, this matchstick model of the Notre Dame Cathedral was quite an ambitious project. Construction of the actual Gothic cathedral in Paris, France was begun in 1163, and completed in 1345. It took 182 years to complete under the guidance of numerous architects. It was the first Gothic structure to use flying buttresses to support the tall, thin walls. Needless to say, Ron’s model took far less time to complete, at 33-1/2” long, 13-3/8” wide, and 24” tall. It’s impressive nonetheless.

Making Time for His Hobby

In addition to the projects he donated to the Craftsmanship Museum, Ron has built several other models. These include, among others, a 3’-long train, and a large hook and ladder fire engine. At the time of this writing, Ron was in the process of moving homes, so his tools and materials were all boxed up. However, Ron was eager to get settled in, and to continue working on his matchstick models. With less display space available, Ron was kind enough to give several models to his children, and donated nine to the Craftsmanship Museum.

For those who look at Ron’s sculptures and say, “You have too much time on your hands,” he often replies, “I don’t watch TV.” Ron’s creations serve as a lesson for those of us who never seem to have enough time, yet regularly indulge in distractions like television. Ron’s collection shows what can be done when that time is put into more productive activity. Additionally, unlike his days as an aerospace engineer, Ron now has something impressive to show for his labor

Ron’s matchstick London Tower Bridge is 71” long. He noted that after starting around Christmas, 2011, the model was completed at 10:07 a.m., April 9, 2012—with the placement of the 5,836th and final piece. Given it’s large size, Ron was very satisfied to see his completed bridge at the end. The two segments of the drawbridge can be raised or lowered as moveable parts for this particular sculpture.

View more photos of Ronald Remsberg’s marvelous matchstick models.