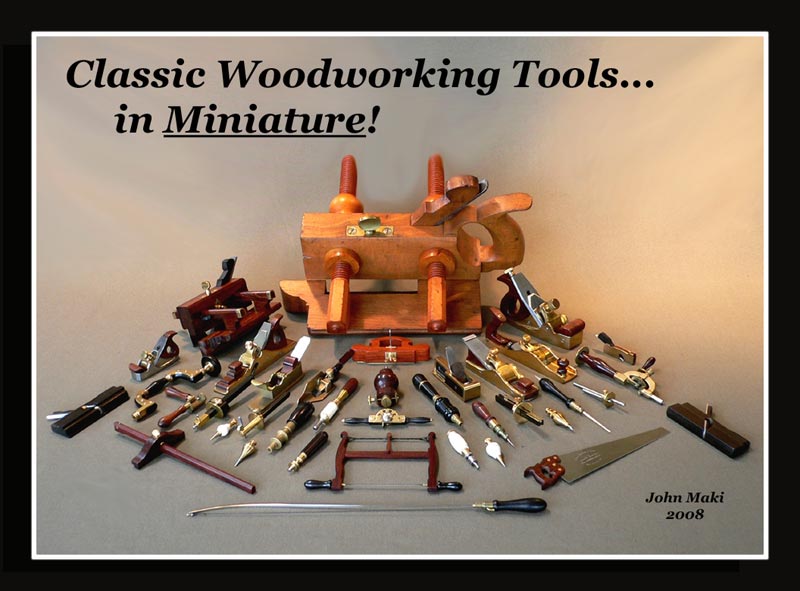

Classic Woodworking Tools Built in Miniature

John Maki displays some of his miniature woodworking tools, along with the full-size vintage tools that he modeled them after.

Introduction

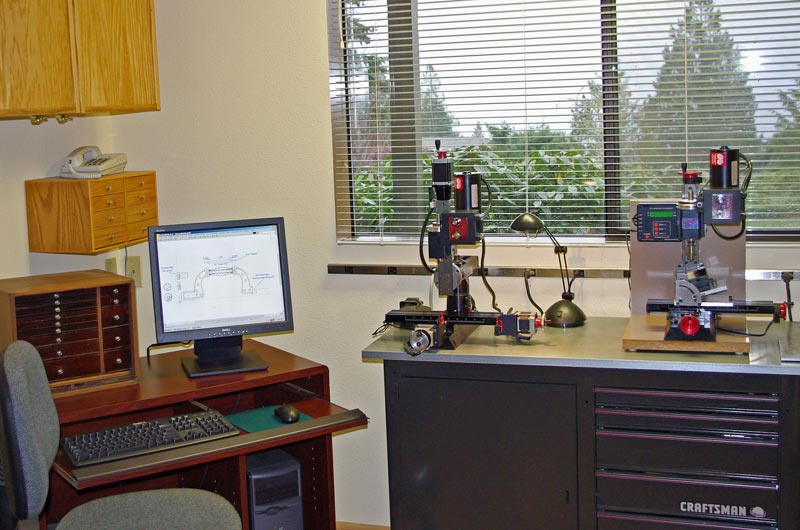

John Maki provides the perfect example of how a small shop, outfitted with relatively inexpensive precision miniature machine tools, can turn out a collection of excellent work. John is also a member of the newer generation of craftsmen who are not afraid to integrate CNC into their tool kit. Although, he typically only uses computer aid for some of the more complicated parts.

In 2010, John visited the Miniature Engineering Craftsmanship Museum in Carlsbad, CA and brought some photos of his work. We were quite impressed with both the quality and quantity of his creations. John uses an assortment of fine hardwoods, ivory, steel, and brass for his miniature creations. They are complete down to the miniature engraved numbers, maker’s marks, and logos.

John has duplicated all sorts of tools in miniature, including planes, saws, measuring tools, and engraving tools. While many collectors spend their time searching for pieces that others have made, John prefers to make his own historical tools. Each piece in his collection is a product of his own craftsmanship. Below, John tells his own story about the origin of his miniature woodworking tool collection, and how he went about creating it.

Taking a Hands-On Approach to Tool Collecting

By John Maki

I have always been a “hands-on” person, with two afflictions. First, I am an admitted tool-a-holic! If it has a sharp edge or a motor, I have to have one! Second, I love detailed miniature things. Beginning as a youngster with scale-model airplanes, then later the collection of miniature cameras, a short stop at miniature steam engines, and then on to scale-model woodworking tools.

I have also enjoyed a technical curiosity, which led me to electrical engineering and a career with 3M Company. Their diverse product lines, and the exposure to multidisciplinary technical teams, provided constant learning opportunities. This eventually led to various management assignments in product and process development laboratories.

Through exposure to mechanical, chemical, electrical, and software engineers—and associations with tool and die makers and manufacturing engineers—I developed an appreciation for the need to continually develop my own understanding of broadening technology.

When I retired, I wanted to further challenge myself, and set about to learn the fundamentals of a metal lathe and a mill. I eventually bought a set of tabletop-sized machine tools from Sherline and began looking for opportunities to put the tools to work. I planned to build steam engines; however, I soon found that they required lots of time to complete.

Steam engines also need a boiler, and eventually require some kind of a machine that could be powered by the combination. The effort became way too complicated, and seriously stretched my attention span.

Fortunately, I ran across an article on Paul Hamler and his miniature tools. The light came on! Although I didn’t have space (or available cash) to acquire a collection of desirable classic tools, I could build a reasonable facsimile in a small and manageable scale. I therefore set my target at 1/3 scale copies of classic European woodworking tools of the Victorian period. The materials of choice would be ebony, Cocobolo, brass, ivory and steel.

It was a perfect solution! I could have my own collection of classic tools, in miniature scale, made using a small lathe and mill. Further, the material cost was almost nothing! Also, I was able to produce a finished tool in 20 to 100 hours, which fell within my personal concentration span.

During the past six years, I have created about 50 different tools, all for my own enjoyment. In the process I have met some great people, including an opportunity to spend personal time with Paul Hamler and Al Osterman. Both of these individuals generously shared their time and expertise, and keep me inspired.

More of John’s miniature woodworking tools with a fountain pen at center for comparison. This is a Victorian Era collection.

Although I am not now, and will never be a fine machinist, learning to use a mill and a metal lathe has forced me to develop a whole new thought process. I have learned how important it is to carefully study and record the design of the target tool, and then plan the entire machining operation before making the first cut!

As I developed a more sophisticated understanding of scale modeling, I added a CAD system, and linked it to a new CNC-controlled Sherline mill. Using this CAD-CAM system, I am now able to design a tool on the computer and send the information to the mill, which precisely cuts the complex curves associated with many of the Victorian designs.

Shop Layout and Tools

My shop is in a single 12 x 16 foot room, with a great view of Puget Sound. Nearly all my work is done using the Sherline tools. They are complemented with a small precision Byrnes table saw, and a 12” Craftsman bandsaw used for rough cuts in wood and brass.

On the right side of John’s shop is a craftsman bandsaw, plus a Byrnes “Model Machines” table saw, and thickness sander. When working on miniatures, it doesn’t take a big shop to house all the necessary tools.

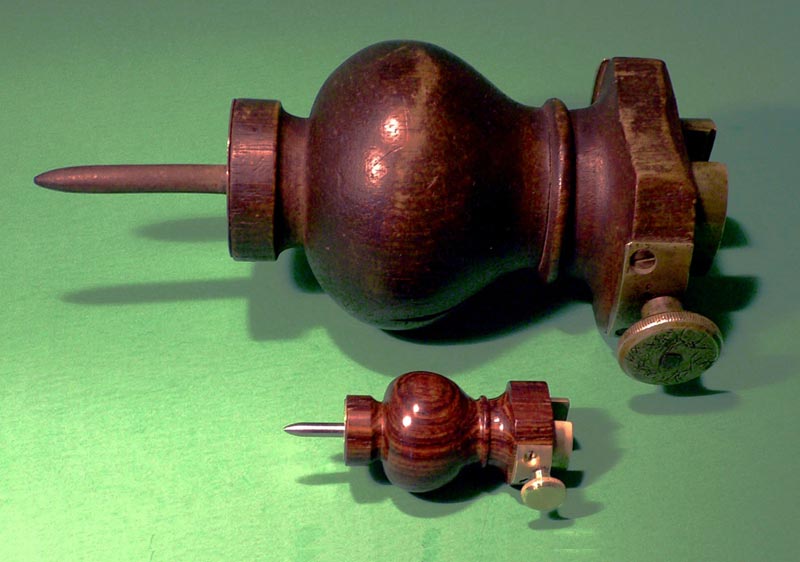

Full-Size Tools Provide the Blueprint

About 1/3 of my miniatures were copied exactly from original examples. I have found I can justify buying an original example of a unique, complex tool which provides accurate dimension and construction details. When I’ve finished the miniature copy, I have been able to resell the originals with little or no financial loss—although I do keep some of the nicer ones for size comparison.

The rest of my tools are based upon photographs from books, auctions, or museums. This approach is much more difficult, since the photos are often taken at some odd angle which defies accurate scaling. Further, I have not yet found a way to get inside a photo to see exactly how the tool went together. However, photos are often the only option when the original tools can only be found in museums.

Another tool in John’s collection is this Norris style smoother. It’s hard to tell from the photo, but this is the 1/3 scale model—not the original.

To learn more about John Maki’s miniature tools, visit his website.

Additionally, view more photos of John’s miniature woodworking tools.

This section is sponsored by:

Makers of precision miniature machine tools and accessories. Sherline tools are made in the USA.

Sherline is proud to confirm that John Maki uses Sherline tools in the production of his small projects.