The Howell V-4 Engine Project—Full Build

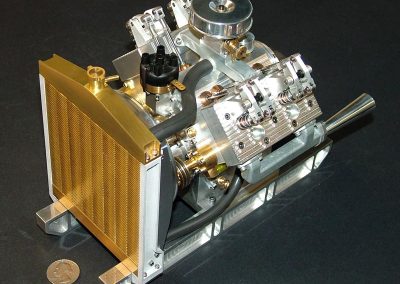

Below we have documented the Joe Martin Foundation Howell V-4 engine build from start to finish. Photos and descriptions of the components illustrate the unique collective craftsmanship—with a beautiful final result.

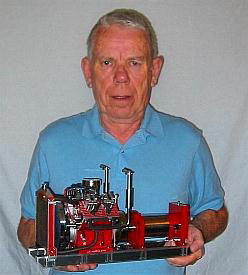

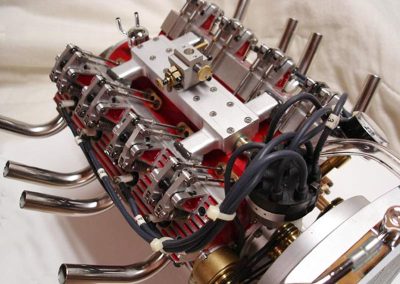

Jerry Howell’s Prototype V-4 Engine

Jerry Howell’s V-4 Engine

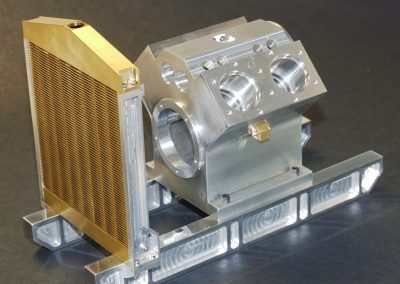

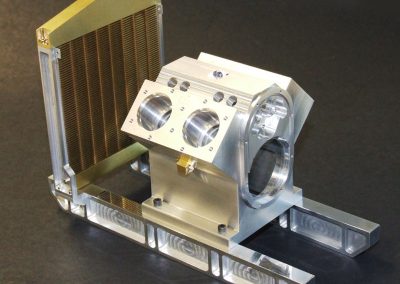

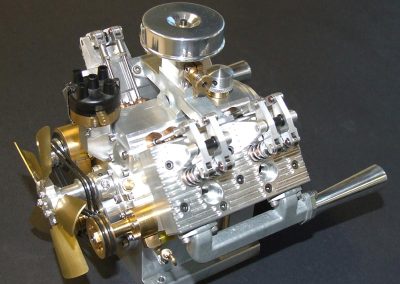

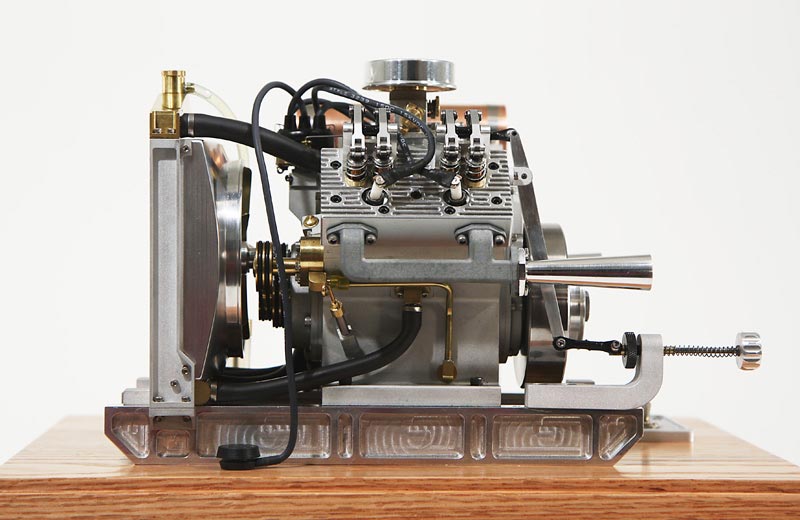

This is what our build team was shooting for. Jerry’s finished V-4 is a thing of beauty, and we were eager to try to replicate it. Compared to the previous photos of Jerry’s V-4, these show the longer rails (cut on a Sherline CNC mill) and generator at the end of the engine.

Jerry Howell’s V-4 Engine

Mounted on the end of the generator is a small LED engine hour meter. Jerry also made some tilting covers to keep rain out of the vertical exhaust pipes.

Howell V-4 Project Starts (9/19/07)

Aluminum Block

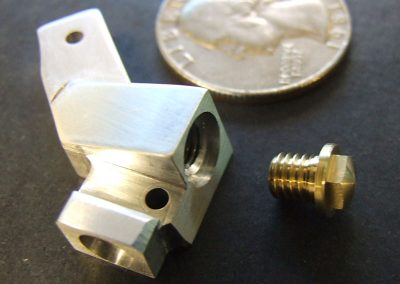

You have to start somewhere. This is the block of 7075 aluminum that Pam Weiss cut on Sherline’s Flow waterjet. A US quarter provides scale reference. This would eventually become the engine block for the V-4.

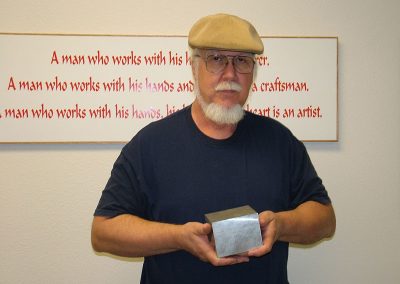

Tom With the V-4 Billet

Tom holding up the blank aluminum block. With time, this plain block would begin to transform into a full-blown internal combustion engine.

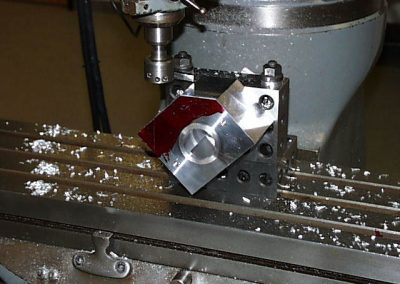

Boring the Crankshaft Hole

The aluminum billet has been squared up to size. The block was bolted to a fixture on a faceplate while the crankshaft hole was bored. (9/25/07)

Howell V-4 Engine Progress—October/November, 2007

Howell V-4 Engine Block

One of the surfaces for the head was cut smooth with an end mill, and then finished with a fly cutter. (10/4/07)

Howell V-4 Engine Block

The cylinder holes on the first side are drilled to make a clearance hole for the boring tool.

Howell V-4 Engine Block

Both cylinder holes on the first bank are completed. The scribed line in red Dychem shows where the second face will be machined for cylinders 3 and 4.

Howell V-4 Engine Block

Tom machined the second cylinder head flat. The block is beginning to take on the V shape. A drill was set to make clearance holes before boring the second bank of cylinder holes. (10/9/07)

Howell V-4 Engine Block

The block was mounted to a large faceplate on the lathe, and a dial indicator was used to find the center of the cylinder holes. (10/19/07)

Howell V-4 Engine Block

The block was removed from the faceplate after each cylinder hole was counterbored.

Howell V-4 Engine Block

The bottom of the block as of late November shows access to the crankcase. At this point, about half of the original material had been removed.

Howell V-4 Engine Progress—December, 2007

Howell V-4 Progress

Machining the spark plug hole and counterbore at a compound angle. The silver vise was held at a 12° while the head on the mill was tilted to 8°. (12/26/07)

Howell V-4 Engine Progress—January, 2008

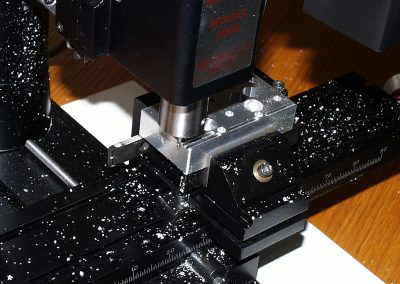

Machining Cooling Slots

A small end mill was used on the Sherline mill to cut cooling slots in the top of the head. (1/3/08)

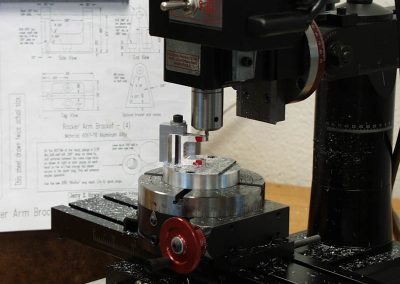

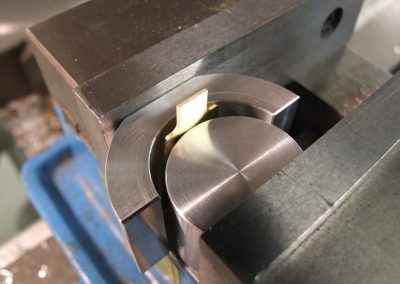

Machining Rocker Arm Brackets

The mill was set up to cut the radius on the end of the rocker arm brackets using a rotary table. (1/10/07)

Machining Rocker Arm Brackets

Note the special clamp that Tom made to hold the brackets during machining.

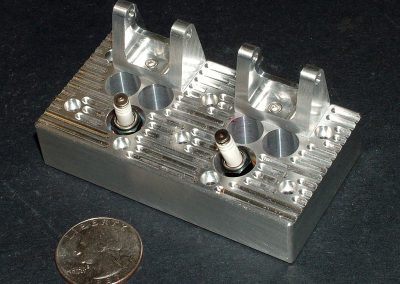

Rocker Arm Brackets

The finished rocker arm brackets. The machining marks were removed with a couple of passes over a stone, or piece of fine sandpaper. Doing so on a flat surface allows the part to transition smoothly from flat sides into the radius.

Howell V-4 Head Progress

One of the heads is shown here with rocker arm brackets and spark plugs installed. (1/24/08)

Howell V-4 Pistons

Bob Seigelkoff made these five aluminum pistons. As we found out in our Seal engine build, it’s always good to have a spare.

Machining the Distributor Drive Housing

Tom Boyer machines a round boss on the distributor drive housing/camshaft end cover. He used a rotary table on the Sherline mill.

Distributor Drive Housing

The finished distributor drive housing and camshaft end cover before the parts were split. (1/30/08)

Howell V-4 Engine Progress—February, 2008

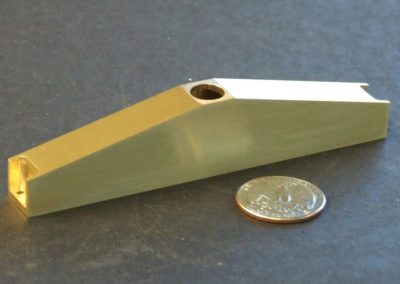

Distributor Spark Advance Arm

The distributor spark advance arm was milled from a solid piece of brass. The curve in the upright portion was made using the rotary table. (2/7/08)

Brass Distributor Housing

Here the finished housing is shown with the spark advance arm attached with two small screws.

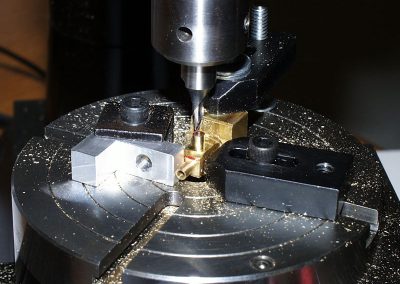

Oil Pump Progress

The body of the brass oil pump inlet elbow was milled to 1/8” OD using the rotary table. (2/21/08)

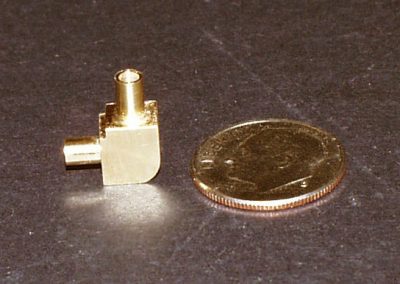

Oil Pump Inlet Elbow

The completed oil pump inlet elbow. Though small, this part required a number of different machining operations.

Howell V-4 Engine Progress—March/April, 2008

Timing Gears

The timing gears were completed by March 10, thanks to some help from Fred Smittle. The gears were made using a Sherline mill and CNC rotary indexer.

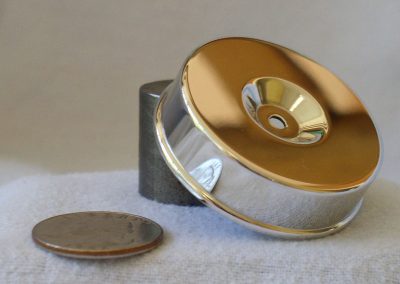

Air Cleaner Cover

The air cleaner cover was completed by Dave Eggert of Mission Viejo, CA. He sent us these photos of the finished part.

Air Cleaner Cover

Dave was still working on some of the brass fittings for the cover at this point, but the photos make clear that he did a really nice job on the part.

Howell V-4 Engine Block

The front face of the engine block was relieved, leaving an oval boss. The front cover exactly matches this shape. The cover also has a raised circular area that fits into a matching countersunk area of the block, in front of the main bearing. (3/20/08)

Howell V-4 Engine Block

This photo shows the cover in place but not bolted on. The machining operations required several different setups on the rotary table to cut the oval shapes.

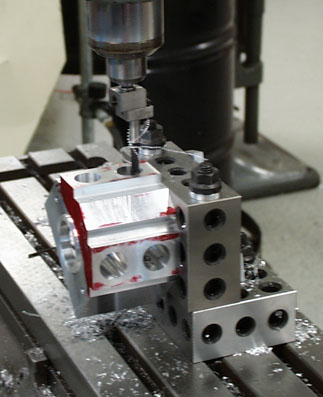

Machining the Engine Block

Tom took this photo while the block was still mounted to the Bridgeport mill table. The sides of the block were being milled away, removing the hold-down fixture holes used earlier. The result was a classic V shape profile. (4/10/08)

Howell V-4 Engine Block

The block was removed from the mill, and the sharp corners were broken slightly with a file. The raw block of 7075 aluminum started out at a weight of 6.32 pounds. At this point, it weighed just 1.42 pounds. Almost 5 pounds of metal had been removed by many machining processes over the course of seven months. With that many hours of work invested in one part, each operation was approached with great care. Tom definitely didn’t want to have to start over now. Consider the photo taken at the beginning of this project of Tom holding the raw aluminum billet—the V-4 engine has come a long way!

Howell V-4 Engine Progress—May/June, 2008

Air Cleaner Cover

Dave Eggert sent in the completed air cleaner cover and mounting components. Although we still had a ways to go before being ready to mount them, it was nice to add these parts to the collection. The finishes are really beautiful, thanks to a great job from Dave. (5/12/08)

Aluminum Rocker Arms

Meanwhile, Tom had been working on the eight aluminum rocker arms, and completed those, too.

Machining Rocker Arms

Tom used this fixture in the rotary table to machine the outer shape of the rocker arms.

Various Fixtures

Shown here are some of the many fixtures that Tom had to make to complete several parts and operations.

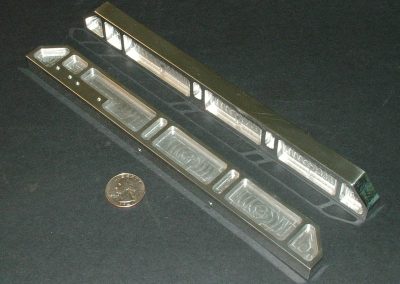

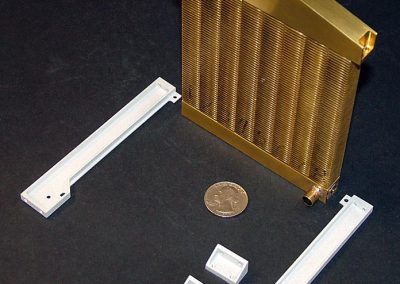

Engine Rails

Adam Krichbaum sent in his CNC machined and polished mounting rails, which the engine and radiator would eventually rest on. (5/16/08)

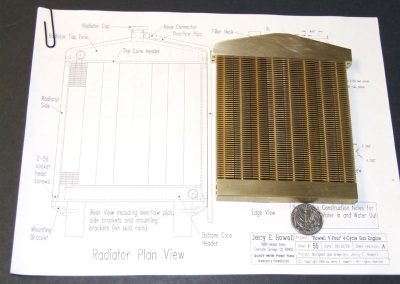

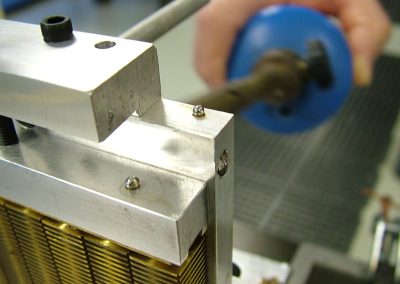

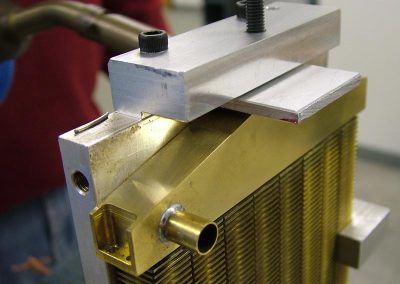

Radiator Progress

By June 6, 2008, Tom had been working on the radiator for a couple of weeks. The tedious part was making the eight brass, finned rods out of square bar stock. Many grooves were cut using the parting tool, and then a hole was drilled down the middle from each end.

Radiator Progress

A top and bottom tank were then made to connect all eight finned rods. This photo shows the eight finned rods assembled with the bottom tank. Aluminum side pieces were also bolted to the top and bottom tanks to act as a support.

Howell V-4 Radiator

The final radiator assembly includes the aluminum side supports bolted into place. At this point, it was almost ready for soldering to seal it up.

Howell V-4 Progress

The radiator lower mounting brackets were fabricated. With that, the radiator could now be bolted onto the frame rails. (6/13/08)

Howell V-4 Engine Progress—July-September, 2008

Machining the Connecting Rods

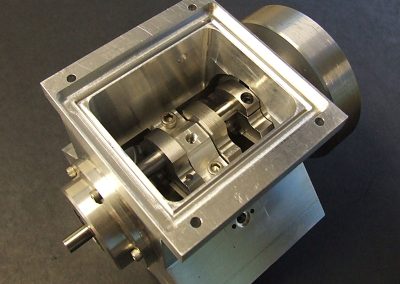

By July 30, 2008, Tom had completed the connecting rods. They are a split base type rod, because the V-4 arrangement of this engine has the two banks of pistons directly opposite each other—as on a double V-twin motorcycle arrangement.

Howell V-4 Connecting Rods

Because the crankshaft is built up inside the case, the bases of the rods do not need to be split and bolted back together. Bronze bushings would be pressed in to provide a wear surface.

Howell V-4 Connecting Rods

The bronze bushings were turned and pressed into the aluminum connecting rods. (8/28/08)

Howell V-4 Engine Block

Also in August, Tom was in the process of turning the four steel piston sleeves, which would be secured in the block using O-rings. The closest cylinder hole has a sleeve in place, while the other sleeve is displayed outside the block. A US quarter provides scale reference.

Howell V-4 Progress

Bronze valve guides were machined for the block and head—eight each, plus a spare. (9/9/08)

Howell V-4 Engine Progress—October/November, 2008

Howell V-4 Crankshaft

The crankshaft parts are disassembled here. The crank elements still needed to be machined to shape and drilled. Then the pins that connect them would be turned to complete the crank.

Howell V-4 Crankshaft

The built-up crankshaft is in progress. The flywheel, collet, pulley, and nut are assembled here, with the other three pieces of the crank laid out behind. (10/10/08)

Crankshaft Counterweights

The crankshaft counterweights were fully machined, ready for installation in the engine block. (11/19/08)

Howell V-4 Crankshaft

Finally, the crank was installed in the block for testing, and it spun as smooth as butter!

Howell V-4 Engine Progress—January-March, 2009

Howell V-4 Camshafts

Tom and Joe decided to grind the camshafts in a conventional manner, rather than using individually machined, glued on lobes—as the plans called for. This gave Joe another chance to try out the Sherline CNC cam grinder that he developed and used for the Seal engine camshaft. Tom turned an extra set of cam blanks just in case. (3/5/09)

Howell V-4 Pushrod Ends

Eight stainless steel clevises and nuts for the pushrod ends surround a quarter for scale.

Howell V-4 Engine Progress—April, 2009

Howell V-4 Oil Pump

Tom finished the components of the oil pump. The gear teeth were cut from cold-rolled gear stock. (4/8/09)

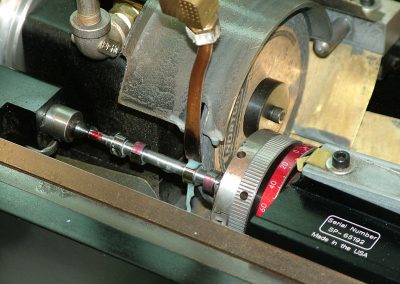

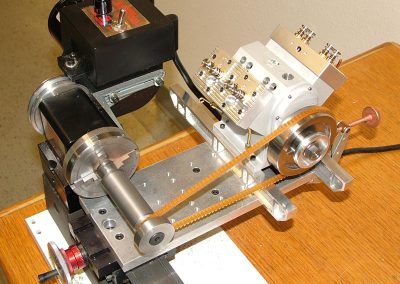

Howell V-4 Oil Pump Test

The oil pump was tested and run-in by powering it with the Sherline lathe for a few hours. The intake hose is in the foreground. Coming from the left side of the pump itself is a stream of oil created by the interlocking pump gears.

Joe Grinding the Cam

Joe Martin is shown setting up and using the Sherline cam grinder to finish the two overhead camshafts for the Howell V-4.

Sherline Cam Grinder

Computer controlled axes move the camshaft back and forth and rotate it while the spinning grinding wheel takes them down to size and shape, one pass at a time.

Sherline Cam Grinder

Jerry’s plans call for individual cam lobes to be pinned and glued onto the camshaft blank, but we decided to grind them in one piece.

Sherline Cam Grinder

The next step was to case harden the camshafts, which Tom would do in the museum shop.

Howell V-4 Camshafts

The first time around, a mistake was made in the orientation of the cams on the shaft. When redoing them, we decided to Harden the blanks first, and then grind the cam lobes after hardening. This provided a better finish on the cams. The second set of camshafts were turned from A2 tool steel, and hardened to 60 Rockwell. The hardening process for the first set is detailed further down this page.

Joe Martin’s cam grinder worked so well that they decided to add the machine to the Sherline catalog. Below you can watch two videos of the cam being ground for this project.

Howell V-4 Engine Progress—May, 2009

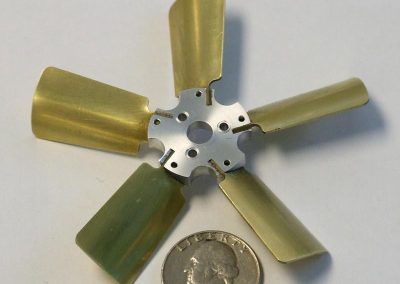

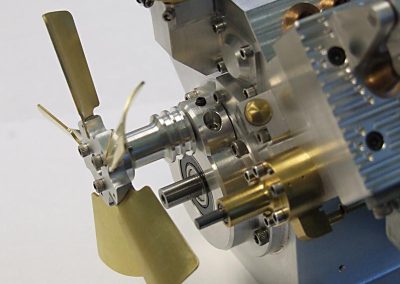

Howell V-4 Fan Blades

Pam Weiss programmed the fan blade profile into Sherline’s Flow waterjet cutter. She then cut five blades from a sheet of brass, leaving only a few small tabs to retain the fans in the sheet. (5/22/09)

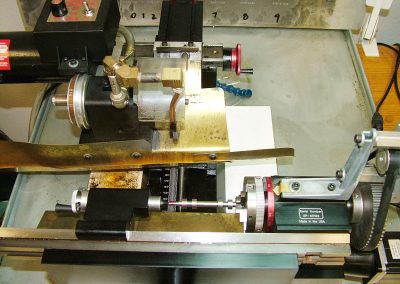

Curving the Fan Blades

Tom then cut the tabs and filed the blades to shape. After which, he used the fixture in this photo to put the required foil curve into each blade. Here, the vise has not yet closed on a straight blade.

Howell V-4 Engine Progress—June/July, 2009

Howell V-4 Progress

The cylinder liners were installed. Then the connecting rods were installed on the crankshaft, and connected to the pistons to make sure everything was in alignment.

Howell V-4 Progress

There were no rings on the pistons yet, so it turned over easily. Either way, it gave Tom some relief knowing that everything lined up and worked smoothly when the crankshaft rotated.

Water Pump Components

The water pump components are laid out. From top center moving clockwise, the parts include: main housing; water outlet; cover and pulley assembly (consisting of pulley, five rare earth magnets, two ball bearings, and black plastic cover); mounting bracket (bottom); impeller assembly (consisting of impeller, shaft, and five rare earth magnets); water inlet; and in the center above the dime is the cutwater. (7/2/09)

Water Pump Drawing

Jerry Howell’s water pump drawing. The magnets in the pulley drive the impeller by magnetic attraction, thereby eliminating the need for a shaft seal.

Howell V-4 PCV Valve

The individual parts making up the PCV valve. From left to right are: the check valve disk; the breather top with brass valve and disk travel limiter installed; and the breather bottom and check valve body assembly.

Howell V-4 Exhaust Tips

Tom’s highly polished, tapered megaphone exhaust tips depart from Jerry’s prototype. These give a racier character to the somewhat industrial looking engine.

Howell V-4 Progress

Tom had also installed a similar exhaust tip on the Seal engine, and we liked the way it sounded.

Howell V-4 Engine Progress—August/September, 2009

Howell V-4 Piston Rings

The original plan was to buy finished piston rings, and grind them to proper thickness. It was eventually decided that they should actually be made in-house. Tom turned these piston rings from cast iron, and heat treated then using Sherline’s heat treating oven. The usual practice is to make about twice as many as needed, as they can break. These 15 rings would need to be enough once final assembly began. The rings are .875” in diameter, and .040” thick. (8/20/09)

Heat Treating the Camshafts

The following photos were taken when we heat treated the first pair of camshafts. (A subsequent pair was heat treated prior to grinding the lobes.) Here the cams are clamped in their holding fixture, ready for heating. (9/4/09)

Heat Treating the Camshafts

The heated fixture, with the cams glowing bright red, is brought out of the oven. Notice this time that Tom is wearing welding gloves. It is incredibly hot next to the open oven door.

Heat Treating the Camshafts

The cams are plunged directly into the Kasenit heat treating powder, and allowed to sit until a coating melts to the surface.

Heat Treating the Camshafts

After scraping off most of the clumped powder clinging to the cams, the fixture is returned to the oven once again. The excess powder is burned off.

Heat Treating the Camshafts

Tom removed the red hot fixture from the oven for a final time, and plunged it into the water tank to cool. The cams must be lowered in straight, so that one side doesn’t cool faster than the other. This keeps the cams from warping. Surprisingly little steam was created in the process.

Heat Treating the Camshafts

The finished heat treated cams ready to be removed from the fixture. They needed quite a bit of cleanup. Unfortunately, after all that work had been done, it was determined that a G-code error in the cam program caused the lobes to be positioned incorrectly. Because of this, a second pair had to be made.

Howell V-4 Engine Progress—November/December, 2009

The second time around, we tried a different approach with the cams. Instead of case hardening the surface, blanks were turned from A2 air-hardening steel, and wrapped in stainless steel foil. They were then brought to 1745° in the heat treating oven. A small piece of paper was placed inside the foil with each blank. The paper would burn up and remove any oxygen trapped inside the foil.

Howell V-4 Cam Blanks

The second set of cams is shown here, hardened and ready for grinding. The ends have already been centerless ground to size in Sherline’s grind shop. A wooden blank was turned from a dowel, and was used with a 4″ saw blade instead of the grinding wheel to test the cam program. We wanted to make sure it was correct this time before grinding the steel blanks. (11/6/09)

Howell V-4 Camshafts

The finished camshaft pair. After finding the simple G-code error, Joe made some changes, and ground the first blank on the Sherline CNC cam grinder. It came out perfectly this time. Tom finished up the second cam, which was a relatively quick process now that the code was dialed in. The cam gears were pressed the next day. (11/11/09)

Howell V-4 Camshaft

Getting the cams ground was the last big hurdle before final assembly. We were getting very close at this point.

Howell V-4 Progress

On December 16, 2009, preliminary assembly of the whole engine was done to test-fit all the parts. The piston rings and cams were installed, and everything turned smoothly. The next project was to solder the radiator parts together. It took over two years to get to this point, but the “first pop” was in sight now!

Tom Soldering the Radiator

The eight brass bars making up the radiator are mounted to an aluminum plate, and paste solder is applied to the joints on the top plate and bottom tank. Heat is applied to back of the aluminum plate with a propane torch. (12/30/09)

Soldering the Radiator

Tom placed small strips of solder on top of the fixture at two points on each side.

Soldering the Radiator

Per Jerry’s suggestion, when the solder melts into a ball (shown here), the solder on the joints of the radiator is also melted. At that time the heat can be removed. Once again, Jerry’s suggestion worked great!

Soldering the Radiator

The top tank is placed in the fixture, and paste solder is applied to the joint. The fixture is again heated with a propane torch. (12/31/09)

Howell V-4 Engine Progress—January-March, 2010

Howell V-4 Radiator

The completed radiator was tested with air pressure while submerged underwater. A small initial leak around the bottom hose fitting was found, and that joint was re-soldered. The radiator now held pressure, and the side plates were ready to be attached. (1/5/10)

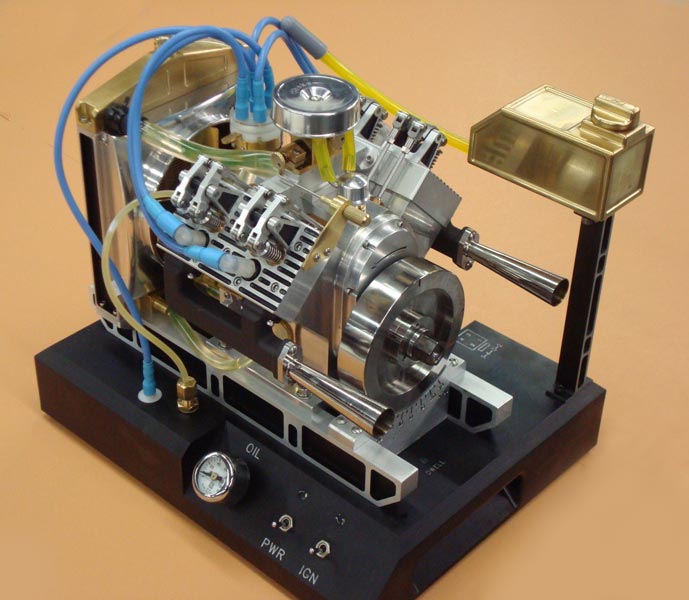

Howell V-4 Engine

An overall shot of the engine and radiator in the preliminary assembly stage. Once all fits were checked, the engine would be disassembled again. Some parts were bead blasted, and others painted, so that the engine could be reassembled for the final time.

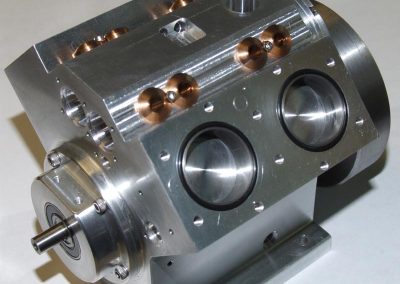

Disassembled Howell V-4 Engine

All of the parts for the Howell V-4 are laid out here prior to final assembly. There are actually more individual parts than can be seen here, because the carburetor, distributor, radiator, oil and water pumps, and other assemblies were not fully taken apart. The block and some of the other parts were bead blasted to give a cast appearance. The rest were left with a natural or polished finish. The final step was to turn this array of parts into a completed engine at last. (1/21/10)

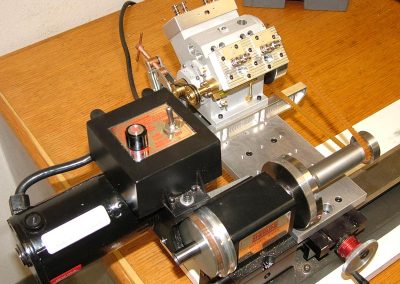

V4runin1

Tom installed the heads, crank, pistons, and rods. Then he hooked the flywheel up to a pulley on the Sherline lathe, and let the engine run for a few hours to seat the piston rings. (2/3/10)

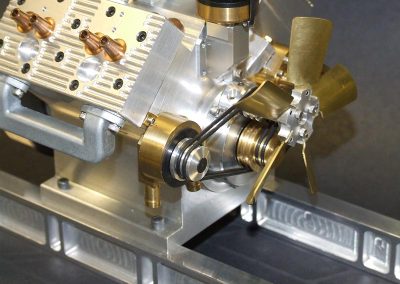

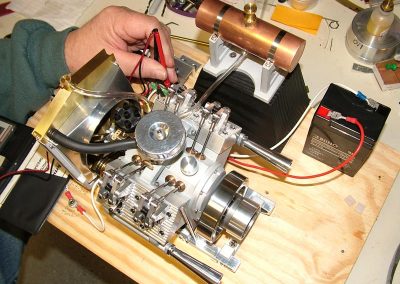

Howell V-4 First Firing

The engine and radiator were reassembled, and then mounted on a temporary “breadboard” to connect the electrical components for a first firing. Tom was checking all the electrical connections to see why the timing light wasn’t turning on. He wondered if it could be a bad Hall sensor. (3/11/10)

Success! Howell V-4 First Pop—March 16, 2010

On March 16, 2010, we successfully completed our second Joe Martin Foundation shop project—the Howell V-4 IC engine. Watch a video below documenting the first pop of the engine, along with the first extended run on March 17.

Congratulations to Tom Boyer and all those who helped for a fine job! The engine was put on display in the Craftsmanship Museum for some time following completion. Tom was happy to start it up for any visitor who wanted to see and hear the V-4 in action. The only remaining tasks were to make a throttle and advance linkage, and to build an attractive display base.

A Note From Jerry Howell’s Family

On behalf of me and my family, we would like to congratulate you and your team on the successful build and run of the Howell V-4. I know Dad was honored to be inducted into your list of craftsmen, and again when you chose to build his V-4.

Dad cannot express his gratitude personally, but again on behalf of my mother Edith, sister Sherry, brother Roger, and myself, we would like to say a big “Thank You” to the Craftsmanship Museum for all you have done to share and promote his work and his legacy.

Sincerely,

Allen Howell & Family

Howell Engines Made by Other Model Engineers

Dave Sage’s Howell V-8 Project

Jerry Howell’s original design began as a kind of double V-twin to make a V-4. Dave Sage took it to a new level by doubling up on Jerry’s design to make the engine into a V-8. Naturally, he had to make his own modifications in order to support the longer built-up crankshaft. He also modified the camshafts to change the timing and firing order, making it more like a Chevy small-block V-8. When asked why, Dave responded, “just for the heck of it.” In these early photos taken soon after the first run, Dave’s V-8 is running a single carburetor.

Dave said that engine speed was limited at this point, and to get more rpm out of it he would probably have to add more carbs. Our only regret is that while Jerry Howell saw the start of this project, he didn’t get to see the ambitious extension of his original design finished and running. It looks like Dave did a first class job that Jerry would have approved of.

Terry Mayhugh’s Howell V-4 Project

Terry Mayhugh started this project—only his second IC engine—shortly after the Craftsmanship Museum started our version. Terry’s first IC engine build was a Howell V-twin. It took Terry about 3,000 hours over the course of two years to complete this engine, but he did a fantastic job. Not only does it look good, but the V-4 runs great, too. Castings for the manifolds were unavailable, so Terry machined his from the plans. Notice also the effective base and innovative gas tank.

Watch a video of Terry’s early run of his Howell V-4 engine.