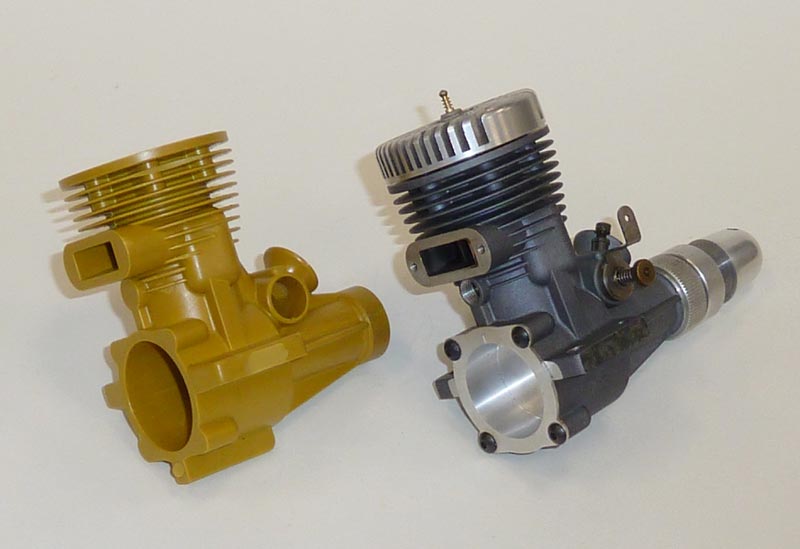

Ralph Cooney designed a number of experimental engines using the investment casting method. Being able to make molds using EDM, he cast the components using the lost wax method. This particular design was cast in aluminum and featured a rear exhaust port and a built-in carburetor. His intention was to make a production cast aluminum engine that needed no steel cylinder sleeve by using what was a relatively new process in the 1980’s to chrome plate aluminum. If the cylinder bore were chromed after boring to size a steel sleeve wouldn’t be needed. Unfortunately, the only companies at the time successfully able to chrome plate aluminum were the large aerospace companies, so Ralph tried a Teflon coating to protect the aluminum. The dark grey engine on the left is Teflon coated, which resulted in the darker color. He ended up having to include a sleeve in the case anyway, and only 5 or 6 of these were ever produced. It was powerful and competitive with other engines at the time but never saw mass production.