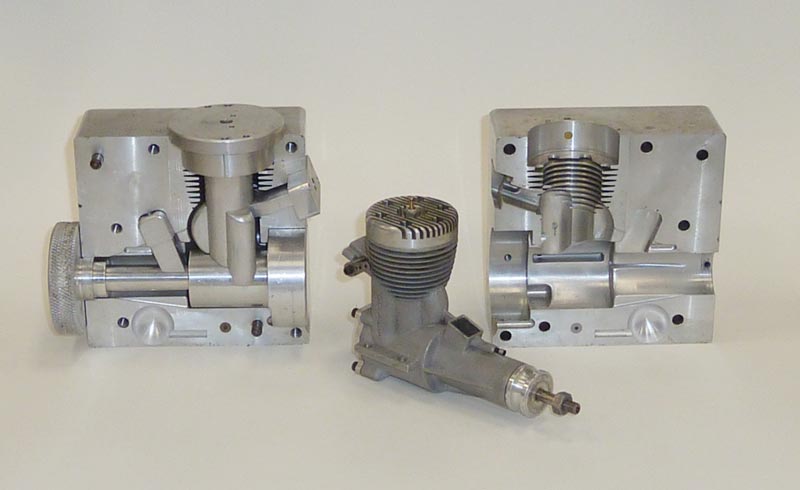

Another rear exhaust port design, this one did not include a cast-in carburetor body. The rear exhaust port was angled upward and had a rotary restrictor plate.

Shown also is a set of molds produced to make a wax copy of the engine crankcase from which a ceramic mold would be made. When the molten metal is poured into the ceramic mold surrounding the wax, it melts and flows out and is replaced by the metal. The mold is then broken open to remove the metal part. This is called the “lost wax” process of molding. For each metal piece, a wax piece is made from the aluminum mold and that wax is then consumed in the final metal casting process. It is slow but yields high quality results for testing a design. It is not intended to make production quantities of parts, and this is the only existing version of this particular engine.