This 1/4 scale model Wright Brothers Flyer has a nearly 12′ wingspan and is historically correct in every detail. The model was made for the 100th anniversary of first powered flight, and was displayed at Kitty Hawk, NC in 2003. The engine is nonfunctional, but materials and techniques used in construction follow as closely as possible to the original specifications. This airplane is one of two identical models built by Robert Cooper. The other was built for a restaurant in an upscale North Carolina community where homeowners could land in their own private planes. The models took two years to build. Details in the models include representations of some of the repairs made by the Wright brothers. The wing spars were signed by personnel at the 100th Anniversary celebration at Kitty Hawk.

Details on the airplane include a model of Orville Wight at the controls. In the photo below, note the sliding platform under his hips. By sliding his hips from side to side, a linkage warped the wings to allow the plane to bank. (This was before the invention of ailerons.) The head and hands were specially made for Robert by George Marsden. The Wright Flyer also includes a 1/4 scale model of the original engine developed by Wright employee Charlie Taylor.

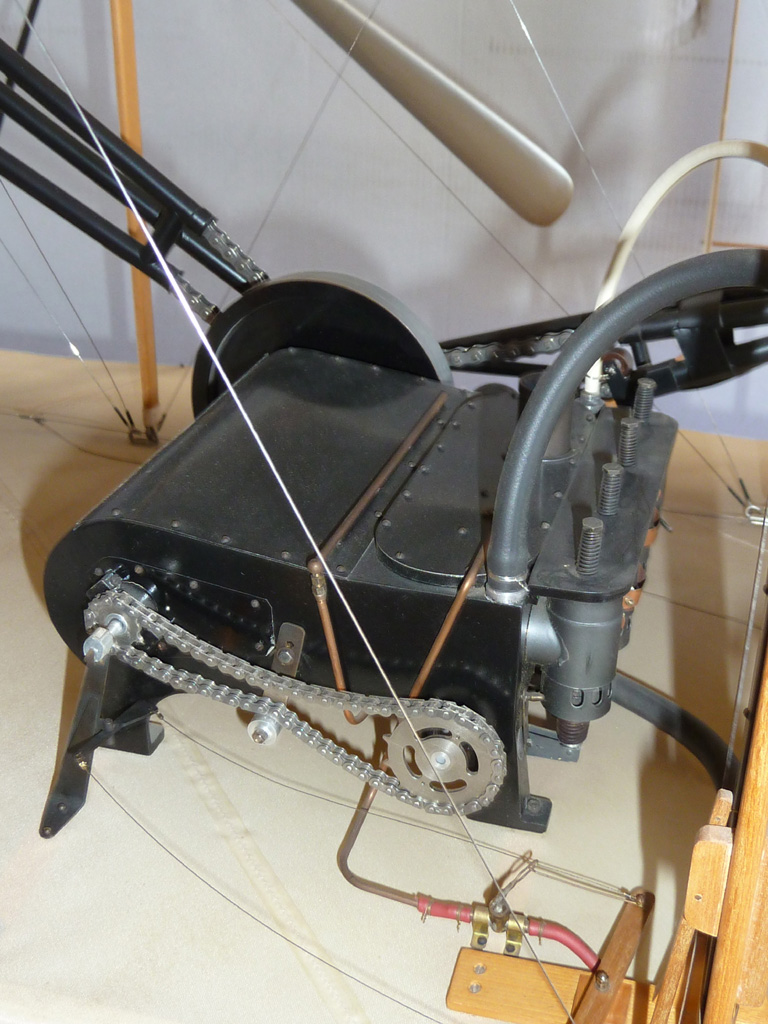

The engine had no carburetor and used a chamber to vaporize the gas/air mixture as the gas dripped slowly in. The mixture was then sucked directly into the combustion chamber when the piston went down. The model plane has an anemometer (air speed indicator), a stopwatch and a distance gauge hooked to measure propeller revolutions were activated at the start of the flight. This left a record of speed, time of flight and distance.

Wires to warp the wing run through a linkage that is accurately duplicated. Note also the correct bias ply cutting of the wing fabric. You can also see how the outer and inner wing panels were connected with stitching. Spars were made from young, fine-grained Spruce out of Seattle. The smallest screws used on the model are 000-90. Others are 0 and 00 size. Many of the materials and techniques of building were related to sailboat construction including the knotting of the waxed cord to hold structures together.