Below you can view more photos of Rudy’s various projects. Click on images to enlarge. All of these projects were donated to the Craftsmanship Museum for display. Where possible, a front and rear view of each engine is shown.

Model Steam Engines, Tractors, and Other Miniatures.

Prairie Type 2-6-2 Steam Locomotive

This locomotive was scratch-built without castings at a scale of 3/8”:1’. It has two double-acting cylinders that have a 7/16” bore, and a piston stroke of 3/4”.

Prairie Type 2-6-2 Steam Locomotive

The locomotive runs on G-scale, or Gauge 1 track (45 mm track gauge), and is alcohol fired.

Prairie Type 2-6-2 Steam Locomotive

The boiler has a working pressure of 75 psi. This model pulls seven nearly identical gondolas, plus a caboose.

2-8-0 Steam Locomotive

He also built five railway express cars, mail cars, and passenger cars to go with this model.

2-6-0 Camelback Steam Locomotive

Another locomotive built at 3/8”:1’ scale. This model has a tender with a fuel bin, which can be configured to look like it runs on either oil or coal. (The boiler is actually fired by alcohol.)

2-6-0 Camelback Steam Locomotive

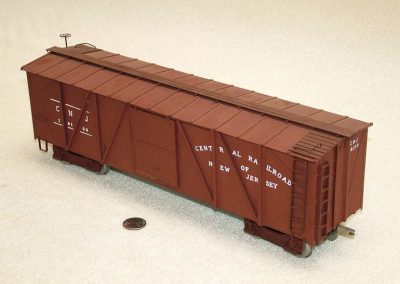

The Camelback locomotive pulls a train of nine scratch-built freight and work cars, plus a “Bobber” caboose.

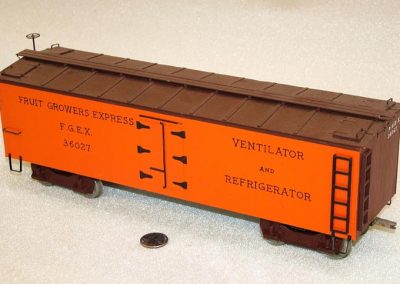

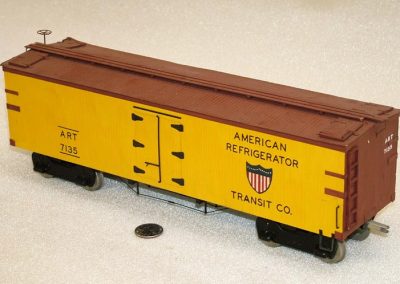

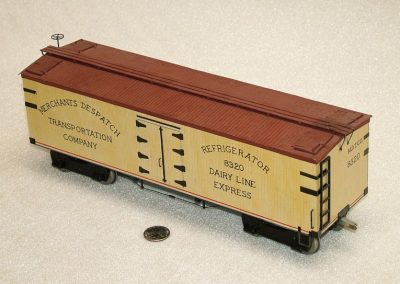

Scratch-Built Refrigerator Car

This scratch-built wooden refrigerator car was made to accompany Rudy’s scale model locomotives.

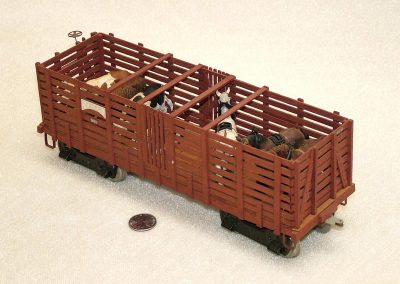

Scratch-Built Cattle Car

Rudy Kouhoupt’s scratch-built cattle car features some happy miniature cows and horses.

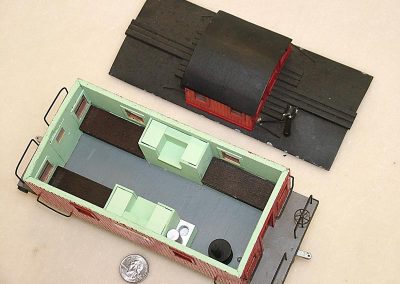

Scratch-Built Caboose

This scratch-built caboose trails at the back end of one of Rudy Kouhoupt’s scale model steam locomotives.

Scratch-Built Caboose

This scratch-built caboose trails at the back end of one of Rudy Kouhoupt’s scale model steam locomotives.

Scratch-Built Bobber Caboose

This scratch-built “Bobber” caboose trails at the back end of one of Rudy Kouhoupt’s scale model steam locomotives.

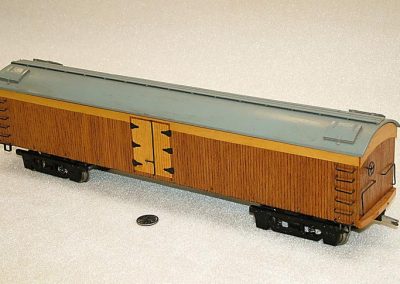

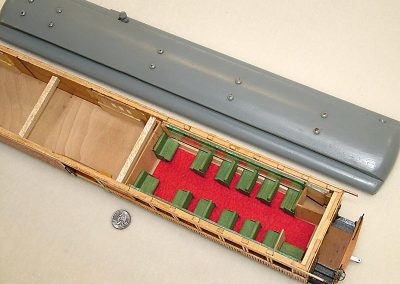

Scratch-Built Passenger Car

This scratch-built passenger car goes along with one of Rudy’s scale model locomotives.

Scratch-Built Crane Car

This scratch-built crane car goes along with one of Rudy’s scale model locomotives.

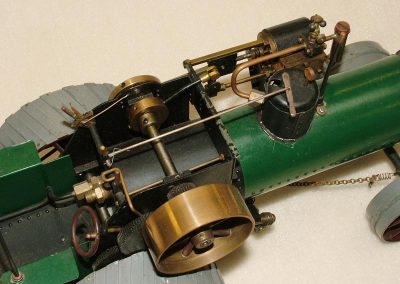

Peerless Model Steam Traction Engine

This miniature steam traction engine was built at a scale of 1-1/4”:1’. Like the Prairie locomotive, this model is alcohol fired, and its safety valve is set at 75 psi.

Peerless Model Steam Traction Engine

Rudy worked from photos he took of the full-size traction engine to design and build the model.

Peerless Model Steam Traction Engine

It has a double-acting engine with a cylinder bore of 5/8”, and a piston stroke of 1”. The gear reduction to drive the rear wheels is 22 to 1.

Peerless Model Steam Traction Engine

Rudy made a three-note chime steam whistle for this model, which makes a pleasant and realistic sound.

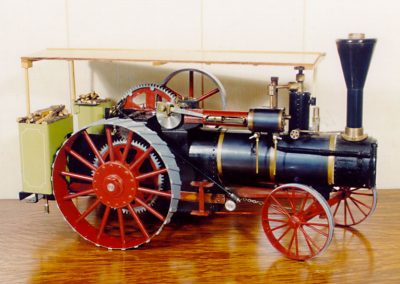

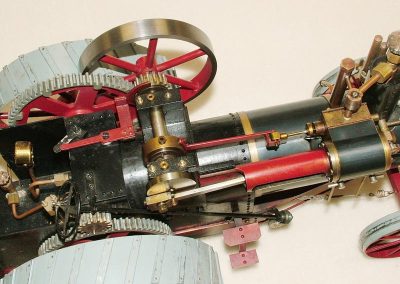

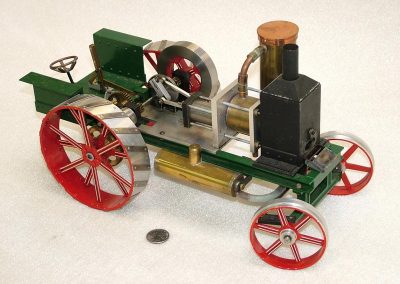

J.I. Case & Co. Steam Traction Engine

This model traction engine, based on a full-size engine from J.I. Case & Co., was built at a scale of 3/4”:1’. Plans for this working model steam tractor were re-released by Village Press in the form of a spiral bound book.

J.I. Case & Co. Steam Traction Engine

Though this model actually burns alcohol to make steam, it looks like a wood burner due to the large boxes on the rear corners filled with firewood.

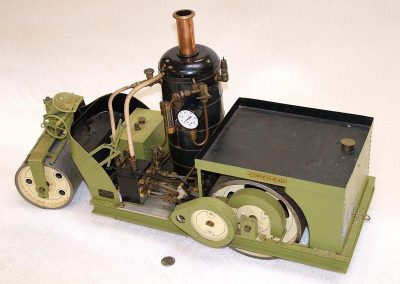

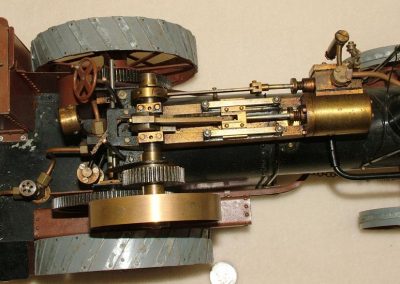

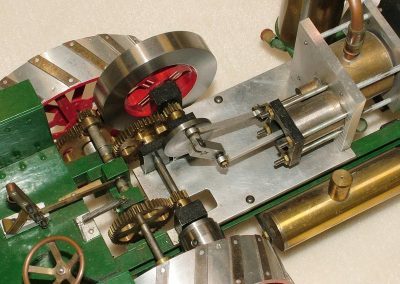

Stirling Engine-Powered Tractor

This tractor resembles a full-size Rumely Oil Pull. It’s driven by a Stirling cycle engine which is water-cooled.

Stirling Engine-Powered Tractor

The tractor has a power take-off pulley for belt operation of other models, such as a wood splitter or cement mixer.

Stirling Engine-Powered Tractor

Many other modelers have built replicas of this tractor from Rudy’s construction series which ran in The Home Shop Machinist magazine. The articles ran in the issues from Nov/Dec 1996 through Nov/Dec 1997.

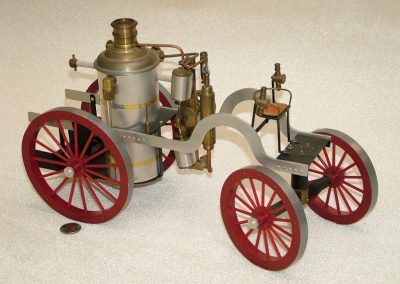

Steam-Powered, Horse-Drawn Fire Pump

This unique model is a steam-powered, horse-drawn fire engine pumper.

Scale Model Water Tank Wagon

This miniature water tank wagon is pulled behind one of Rudy Kouhoupt’s scale model steam traction engines.

Scale Model Engines

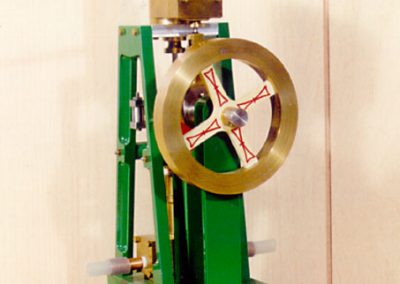

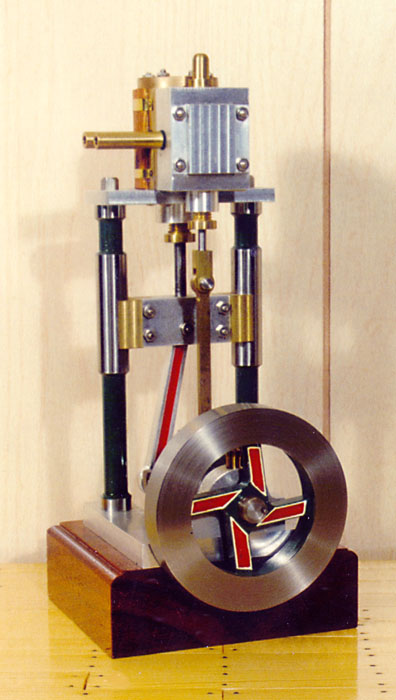

Vertical Steam Engine With Hypocycloidal Planetary Drive

The hypocycloidal planetary drive provides a system for guiding the piston rod in a straight line, as the double-acting piston travels through it’s cylinder. The piston has a 1-1/2” stroke, while the cylinder has a 3/4” bore.

Vertical Steam Engine With Hypocycloidal Planetary Drive

Rudy fabricated all the parts of the engine from stock materials, including both the internal tooth and external tooth gears—which he cut on his shaper.

Vertical Steam Engine With Hypocycloidal Planetary Drive

You can see a video of this engine in action at the bottom of Rudy’s craftsman page.

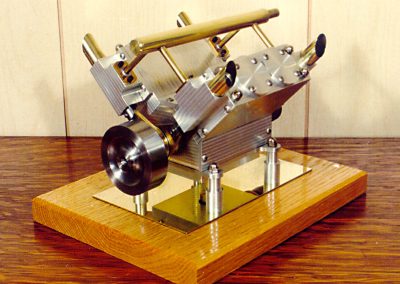

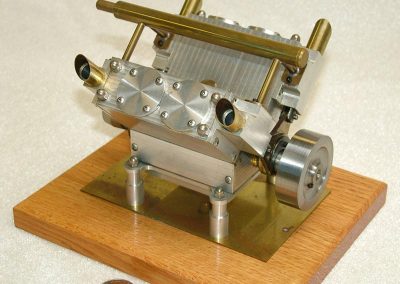

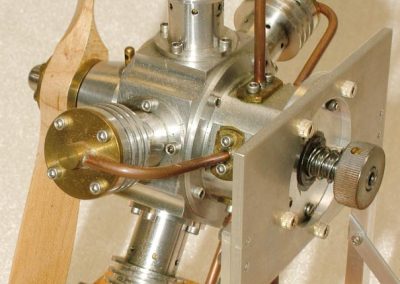

V-4 Steam Engine

The four single-acting cylinders on this unusual steam engine have a bore of 7/8”, and accommodate pistons with a stroke of 7/8”.

V-4 Steam Engine

The admission and exhaust events are regulated by pressure-balanced inside admission piston valves, which operate with very low friction.

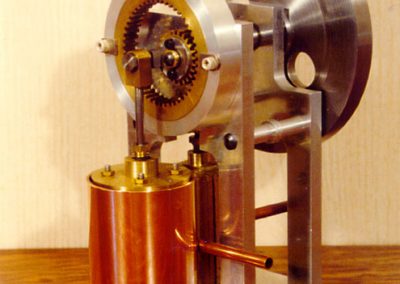

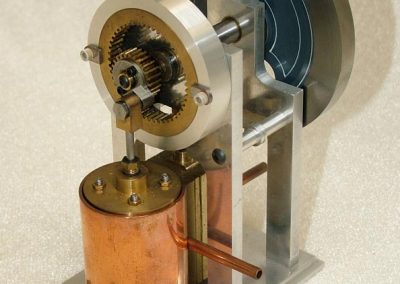

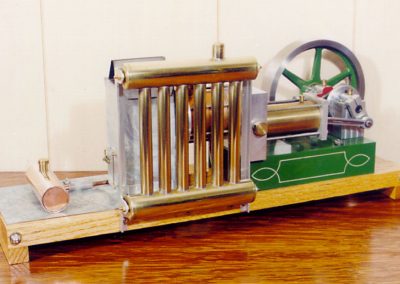

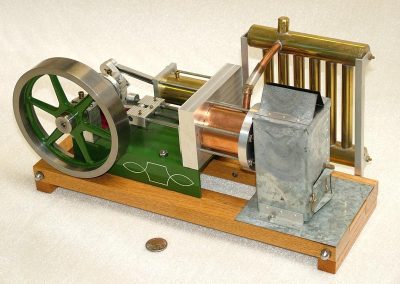

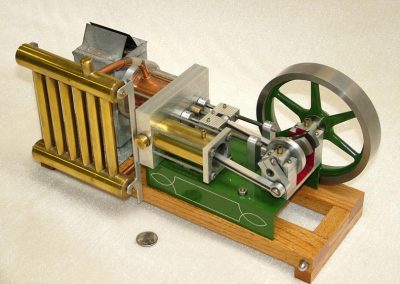

Water-Cooled, Hot-Air Stirling Engine

The brass radiator provides efficient convection cooling for this hot-air engine, which runs on the Stirling cycle.

Water-Cooled, Hot-Air Stirling Engine

The engine has two cylinders. The displacer cylinder heats and cools the air, while the internally connected power cylinder generates the force to run the engine.

Water-Cooled, Hot-Air Stirling Engine

The heat to run the engine is supplied by a small alcohol burner.

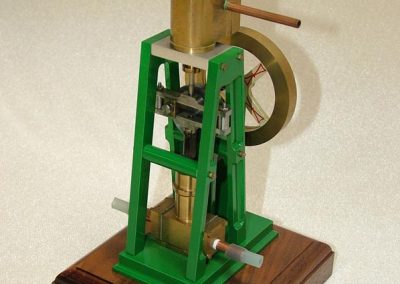

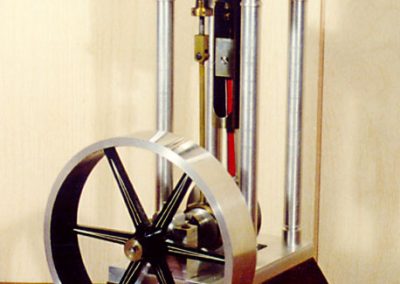

Steam-Powered Water Pump

This is a flywheel type steam pump in which the steam cylinder at the top and the water pump cylinder at the bottom are connected by a Scotch yoke mechanism.

Steam-Powered Water Pump

Rudy designed unusual flap valves for the water pump to give it high efficiency.

Steam-Powered Water Pump

Rudy also wrote a construction series on the flywheel pump that ran in Live Steam magazine. These articles ran in the issues from Nov/Dec 1997 through Sept/Oct 1998.

“Well Pump” Steam Engine

This unique steam engine was built using an old well pump from Rudy Kouhoupt’s family property.

“Well Pump” Steam Engine

The cast iron body pumped water for many years, and now it lives on in another useful form.

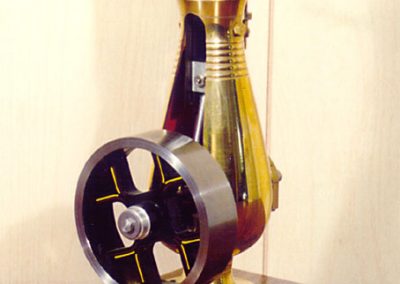

Coke Bottle Frame Steam Engine

Having a cylinder bore of 7/8”, and a piston stroke of 1-1/4”, this ornate double-acting steam engine is both attractive and powerful.

Coke Bottle Frame Steam Engine

All parts were fabricated, except the frame of the engine, which Rudy machined from a cast brass bud vase.

Coke Bottle Frame Steam Engine

It took some interesting milling machine work to make the engine from a vase!

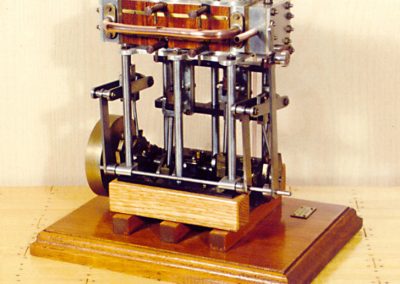

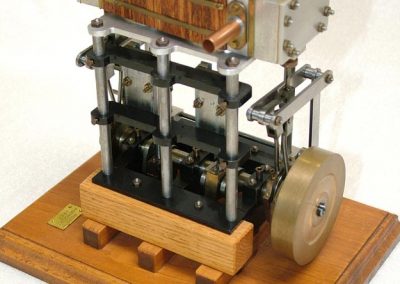

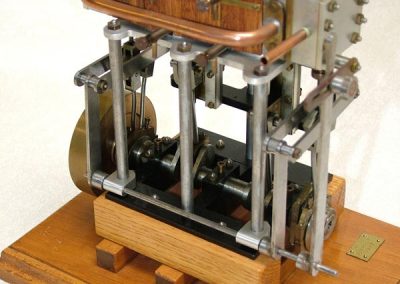

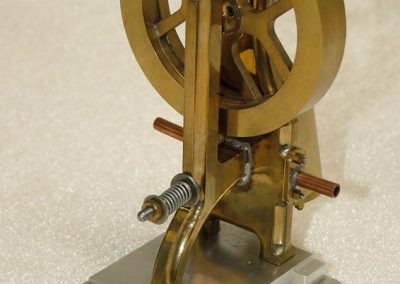

Two-Cylinder Compound Expansion Marine Engine

This is a model of a “fore and aft” type compound steam engine. This kind of engine had marine applications in powering tug boats, trawlers, and similar craft.

Two-Cylinder Compound Expansion Marine Engine

It has a fully working Stephenson link motion for reversing and controlling the point of cutoff for both cylinders.

Two-Cylinder Compound Expansion Marine Engine

Rudy’s construction series on building this fore and aft compound ran in Live Steam magazine, in the issues from March through November 1988.

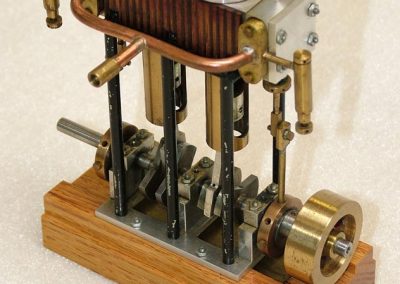

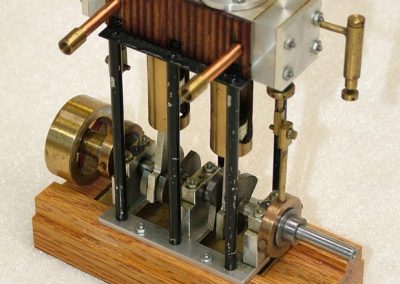

Two-Cylinder Marine Steam Engine

This two-cylinder marine steam engine would have been used to power a small boat or launch.

Two-Cylinder Marine Steam Engine

This engine can also be seen in the steam engine video link on Rudy’s craftsman page.

Stationary Steam Engine

This workhorse steam engine has combined guide and column supports. The rugged design of this steam engine is unusual, as it combines the functions of crosshead guide and cylinder support in a single set of columns.

Stationary Steam Engine

It’s a robust engine which was, according to Rudy, “a little workhorse.” The double-acting cylinder has a bore of 3/4” and a piston stroke of 1”.

Stationary Steam Engine

Rudy also wrote a construction series on building this engine, which was published in Live Steam magazine, in the issues from May/Jun 2000 through Nov/Dec 2000.

Open Column Stationary Steam Engine

This open column stationary steam engine features a trunk type crosshead guide.

Open Column Stationary Steam Engine

The double-acting cylinder has a bore of 1”, and a piston stroke of 1-1/4”.

Open Column Stationary Steam Engine

All of the parts for this engine were fabricated, with no castings used.

Vertical Steam Engine

This small open column vertical steam engine further illustrates the range of different projects that Rudy Kouhoupt tackled.

Vertical Steam Engine

This Overcrank vertical steam engine features a unique system of links and levers to guide the piston rod.

Vertical Steam Engine

This unique miniature vertical steam engine features a tiny wooden barrel up top.

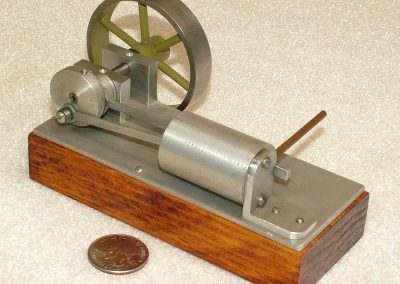

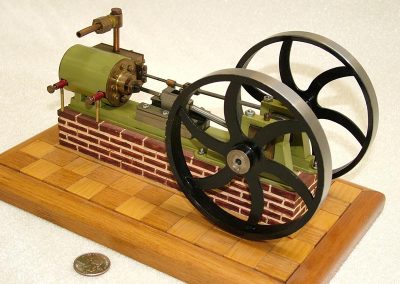

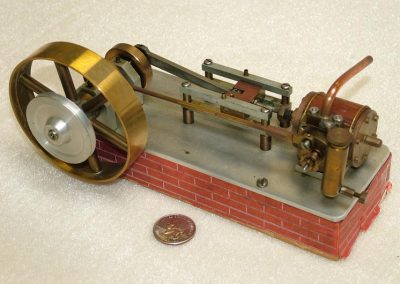

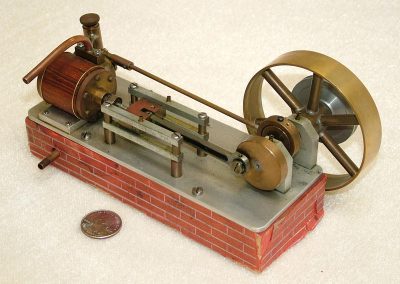

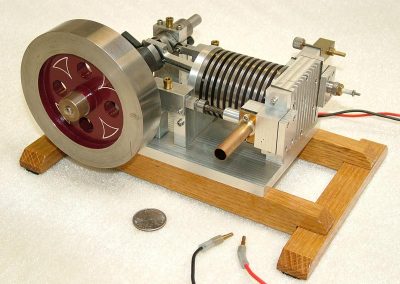

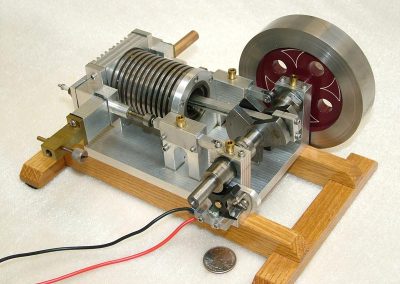

Horizontal Steam Engine

This tiny horizontal steam engine is one of many built by Rudy Kouhoupt. A US quarter in the photo provides scale reference.

Horizontal Steam Engine

No castings are used in this engine design, which features curved spokes in the twin flywheels.

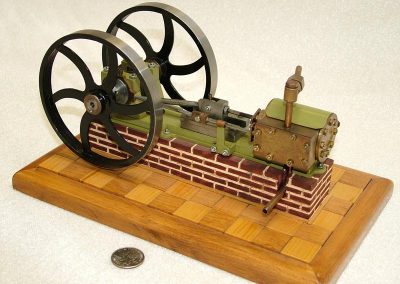

Horizontal Steam Engine

This single-cylinder, dual flywheel steam engine features a brick facade on the base.

Walking Beam Steam Engine

This scale model walking beam engine is hooked up to run on compressed air while on display at the Miniature Engineering Craftsmanship Museum.

Walking Beam Steam Engine

You can see this engine running in the steam engine video link at the bottom of Rudy’s craftsman page.

Walking Beam Steam Engine

This walking beam steam engine has an interesting geared pattern on the outside of the flywheel.

Walking Beam Steam Engine

A version of this engine can also be seen in the walking beam engine video link at the bottom of Rudy’s craftsman page.

Radial Steam Engine

Though normally associated with airplane engines, steam engines can also be built with radial pistons driving a central crankshaft.

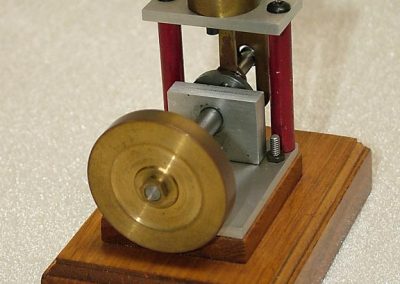

Oscillating Steam Engine

This oscillating steam engine, designed and built by Rudy Kouhoupt, has served as a great beginner project for eager model engineers.

Oscillating Steam Engine

The following photos show some of the smaller projects that Rudy built over the years.

Oscillating Steam Engine

This small oscillating steam engine is another illustration of the variety of different configurations built by Rudy Kouhoupt.

Oscillating Steam Engine

Rudy’s miniature oscillating steam engine captures the solid construction and smooth running characteristics of its full-size counterparts.

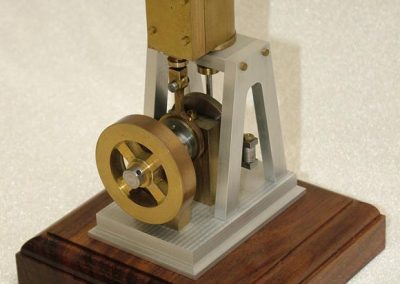

Vertical Steam Engine

This small vertical steam engine is hooked up to run on compressed air while on display at the Miniature Engineering Craftsmanship Museum.

Vertical Steam Engine

This small vertical steam engine is hooked up to run on compressed air while on display at the Miniature Engineering Craftsmanship Museum.

Oscillating Steam Engine

This small oscillating steam engine is yet another simple and functional design by Rudy Kouhoupt.

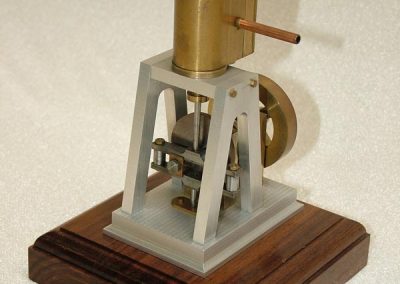

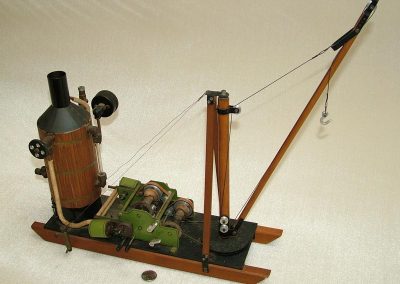

Steam Engine With Boiler

This engine was built as a complete steam plant with its own operational boiler to produce steam.

Steam Engine With Boiler

This miniature steam engine was modeled after a typical logging “donkey” engine with hoist on skids.

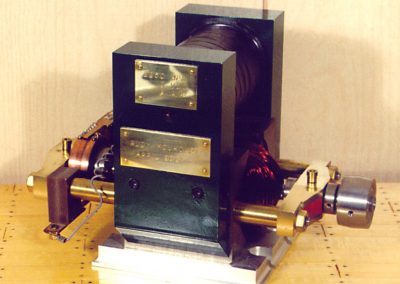

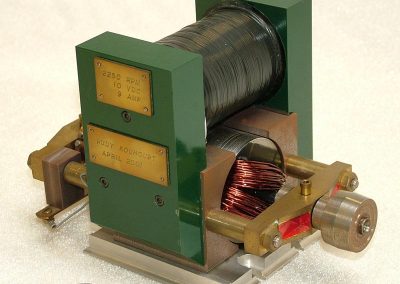

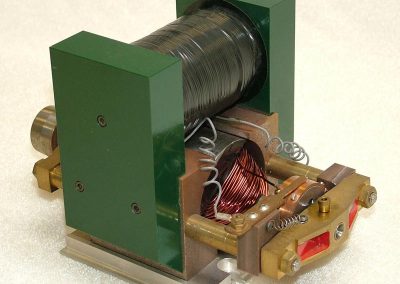

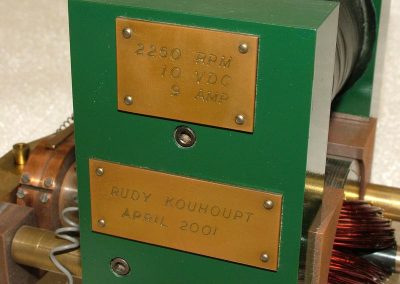

Miniature Dynamo

Rudy built this direct current dynamo, which delivers 9 amps at 10 volts. The field coil is shunt wound so that the dynamo is self-exciting.

Miniature Dynamo

This dynamo was entirely fabricated without the use of castings. It has an output of 90 watts at 2250 rpm.

Pioneer Non-Compressive Internal Combustion Engine

This Pioneer non-compressive engine is one of the last engines that Rudy built. It serves as a nice reminder of the wide variety of projects that he was involved with.

Pioneer Non-Compressive Internal Combustion Engine

Rudy explained what a non-compressive engine is in the last video linked at the bottom of his craftsman page. The engine is now part of the Craftsmanship Museum collection.

Rudy at a Model Engineering Show

Rudy is shown here at a model engineering show on September 29, 2002. He was explaining some of his engines, and selling some of the books and plans that featured his designs. From the 1960’s onward, Rudy wrote over 250 magazine articles, and also shared his time and expertise with at-risk school children and other groups.