Below you can view more photos of Roger Zimmermann’s scale model cars, and the construction techniques he used to build them. Click on images to enlarge.

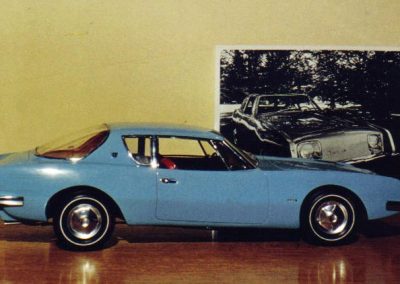

The Revised 1/12 Scale Studebaker Avanti Model

Original Avanti Model

Several views of the first iteration of the body show that the shade of blue paint is not quite correct. Also, the leather interior is a little too dark. This would eventually be corrected in the final version.

Original Avanti Model

The small badge on the fender behind the front wheel indicates this model was the supercharged version, which was available as a factory option.

Original Avanti Model

The small badge on the fender behind the front wheel indicates this model was the supercharged version, which was available as a factory option.

Avanti Interior Upgrade

Roger then dyed the interior with the proper color of turquoise, using actual Studebaker vinyl spray colors. The leather was shaved thin and applied to the carved seat forms with glue.

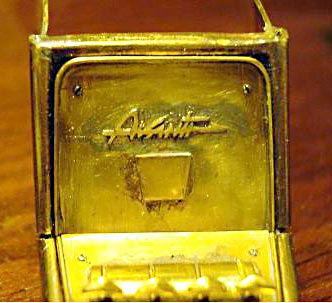

Avanti Center Console

The brass “shift boot” for the 4-speed shifter, and the opened center console lid.

Avanti Center Console

The center console features the Avanti logo along with four temperature and ventilation control levers.

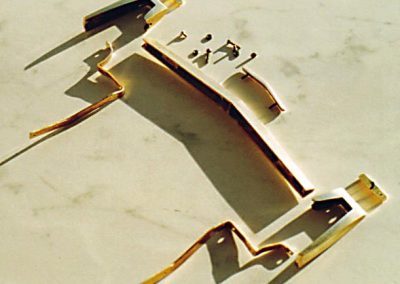

Avanti Rear Windows

The rear windows of the Avanti did not roll down, but they could be popped out from the rear to help draw air through the cockpit. This was another innovation that would be adopted by many others. Here the brass frame was test-fit to the body prior to chroming.

Avanti Door Upgrade

After replacing brass components inside the door, the interior panel was then installed to cover the mechanism.

Avanti Door Upgrade

Beige and turquoise leather portions were added with strips of padding underneath to give them a “tuck and roll” pattern.

Avanti Model Detail

A close-up shows the unique Studebaker conical pin door locking mechanism. This was designed to provide extra security, and probably also to guide the extremely long and heavy doors into position.

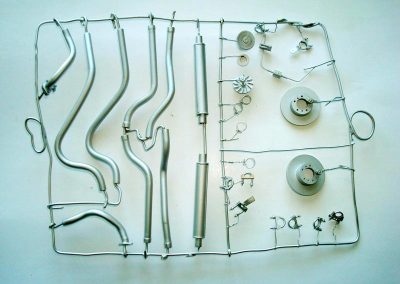

Brass Avanti Components

These parts were satin chromed to represent a galvanized, or non-shiny steel finish. This was applied to the exhaust system and disc brake rotors, among other pieces.

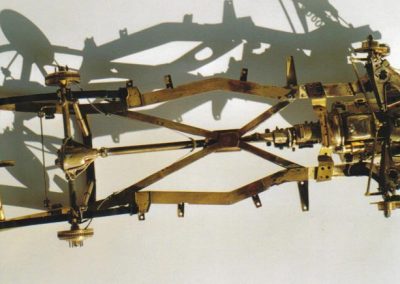

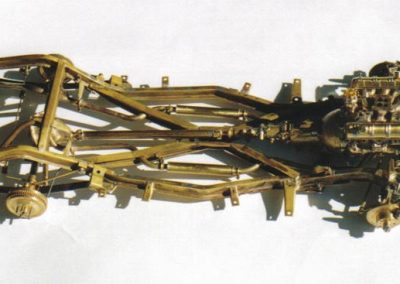

Avanti Frame

The painted frame is shown here and in the following photos during various states of assembly.

Avanti Frame Upgrade

Here the engine and its accessories were installed. As on the original, the distributor and spark plug leads are shielded by stainless steel panels to prevent static on the AM radio. This pre-dated the modern trend of covering engine components by about 40 years.

Avanti Tire Construction

The following photos document Roger’s process for making new Avanti tires. To turn the master for his tire mold, brass bar stock was held between a 3-jaw chuck and live center on his lathe. This method was described in Gerald Wingrove’s comprehensive book, The Complete Car Modeller.

Avanti Tire Construction

The tire tread was cut into a strip of flat brass, which was then “soft welded” to the outside of the tire shape.

Avanti Wheel Covers

Roger made these wheel covers with an inner and outer piece to give the impression of raised spokes.

1/12 Scale Model Studebaker Avanti

Roger’s finished 1/12 scale Studebaker Avanti is truly a thing of beauty.

1/12 Scale Model Studebaker Avanti

Keep in mind this car was introduced in 1963. It is a shame only several thousand of these daring and innovative cars were made.

1/12 Scale Model Studebaker Avanti

Roger went to great lengths to incorporate every tiny detail on his model.

1/12 Scale Model Studebaker Avanti

A customer could choose supercharging or air conditioning, but not both, which is why the supercharged cars are seen less often.

1/12 Scale Model Studebaker Avanti

Inside and above the rear seats is the padded foam cover over the built-in steel roll bar. This was the final touch to a car that was way ahead of its time.

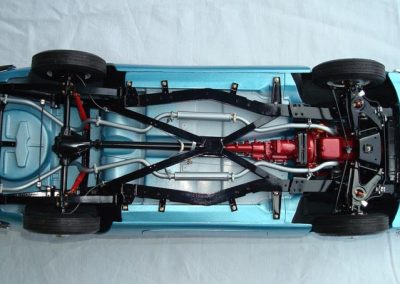

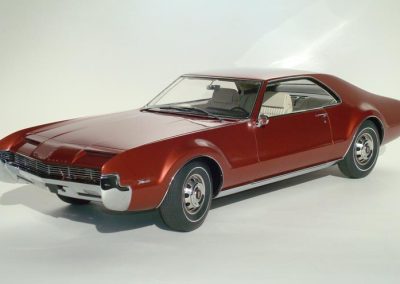

1/12 Scale 1966 Oldsmobile Tornado

1/12 Scale 1966 Oldsmobile Tornado

Roger’s sleek 1/12 scale 1966 Oldsmobile Tornado is even more detailed than the Avanti in many respects.

1/12 Scale 1966 Oldsmobile Tornado

The Tornado model even includes working electric window lifts, and a powered front wheel drive. Roger did this mostly just to see if he could!

1/12 Scale 1966 Oldsmobile Tornado

From under the hood to under the car, no detail escaped Roger’s attention.

1/12 Scale Continental Mark II

In November 2010, Roger was in the process of making his next model car—a 1/12 scale Continental Mark II. He sent along some photos of his early progress on the project.

Continental Mark II Construction

Roger started out this project by building some of the smaller parts first. The brass windshield wiper motor was starting to take shape here.

Continental Mark II Construction

The following photos show construction of the valve covers. Layers of brass stock were aligned on a central core and milled to the shape of the cover.

Continental Mark II Construction

Thinner but larger plates were then inserted on the same rod between each thicker piece, and then machined to the contour of the outside of the fins.

Continental Mark II Construction

A Continental logo was cut from thin stock and soldered to the assembly.

Continental Mark II Construction

The nearly completed valve cover. In the mid-1950’s, Continental was a division of its own. That’s why you won’t see the Lincoln brand applied to this car.

Continental Mark II Construction

These last photos show Roger’s process for making the hubcaps. Continental hubcaps have a pattern of fins or vanes that is very complicated. To duplicate it, Roger first turned the basic hubcap shape in brass.

Continental Mark II Construction

A mill with a slitting saw was used to cut 40 slits on the cap surface.

Continental Mark II Construction

Each vane took about one hour to make and solder in place, so you can estimate how long it took to complete each hubcap. Wow!