Below you can view more photos of Paul Hamler’s miniature tools and guns. Click on images to enlarge.

Miniature Woodworking Tools

Paul Hamler With a Miniature Woodworking Tool

Paul displaying one of his miniature tools at the 2003 Cabin Fever show in York, PA.

Paul’s Briefcase of Miniatures

Another picture of Paul’s briefcase from the Cabin Fever show (2003). Note the saws tucked into the flap on the lid of the case.

Various Miniatures

A separate glass-covered display case houses some of Paul’s spokeshaves, powder horns, and an ornate slotting plane.

Charles G. Miller Patent Plane

This finely detailed plane was photographed in a display box at the Cabin Fever show, with a quarter for scale reference.

Full-Size Miller Patent Plane

This is a photo of the original full-size Miller Patent plane for comparison. Considering its size, Paul’s model captures an amazing amount of the original’s fine detail.

The Original Rabbit Plane

With tongue firmly in cheek, Paul presented the Joe Martin Foundation with one of his fun pieces, which he calls, “the Original Rabbit Plane.” The model is actually a tiny functional plane, and while it may not be very ergonomic, it is certainly charming. A quarter gives reference to the small size.

Fleetwood Treadle Saw

Another treadle scroll saw by Fleetwood of Wilmington, DE, from around 1884. This model was also made at a scale of 7.5:1.

Stanley Type 4 Multi-Plane

This angled view of the multi-plane shows it as it would have been seen in catalogs of its era. In those days, a good craftsman expected their tools to last a lifetime. The care put into these tools, and their ornate decoration, reflects the importance a craftsman places on the quality of their tools and work.

Stanley Type 4 Multi-Plane

This model was made in 1/3 scale, and captures all the fine details of the original.

Miniature Kentucky Long Rifles

Long Rifle Firing Mechanism

In this photo, the firing mechanism for the rifle is seen at full-size, 1/2 size, and 1/3 size. This image dramatically illustrates how much smaller 1/3 scale really is—even when compared to 1/2 scale. While this increases the challenge of making small parts, 1/3 scale yields a final product that is small enough to be considered “miniature,” while also exhibiting all the details and function of the original.

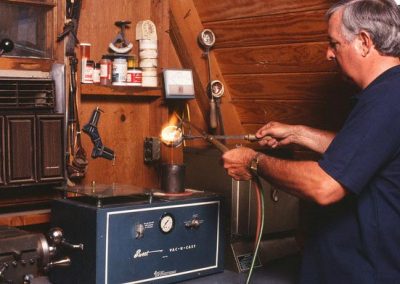

Casting Process

The molding and casting process shows the full-size part, the scaled down mold, a model of the part, a wax of the model, and the final cast piece.

Engraving Setup

The setup for engraving includes a stereo microscope. This makes it possible to see the fine detail when using a pneumatic engraving tool.

Finishing the Long Rifles

Several models are shown in various states of finish. All that’s left is to stain and finish the stock.

Miniature Colt M1911 Pistols

Lost-Wax Process

Once a master pattern for each part is made, the molds for wax casting are created. The pink wax seen here has the sprues attached. (A sprue is the pathway for metal to flow into the mold.) The wax is then encased in a plaster mix. After the plaster dries, the wax is heated up and flows out—leaving a detailed cavity. The cavity is then filled with molten metal.

Lost-Wax Process

Once everything cools down, the plaster cast is broken, leaving the metal part. This is called the lost-wax process. While it may be slow, it produces very detailed, high quality parts. This photo shows some of the wax parts compared to their full-size counterparts.

Magazine Spring

A lathe is used to wrap wire around a piece of rectangular metal to make the magazine spring.

Colt Castings and Parts

Sets of castings and parts for Paul’s Colt miniatures. Before the final assembly is completed, the functional miniature weapons will have the appropriate parts either blued or nickel plated. Paul would later add different grips and engraving on some pistols.