Below you can view more photos of Ken’s airplanes and other projects, with some of the steps for building them. Click on images to enlarge.

1/15 Scale Sopwith Camel

Sopwith Camel

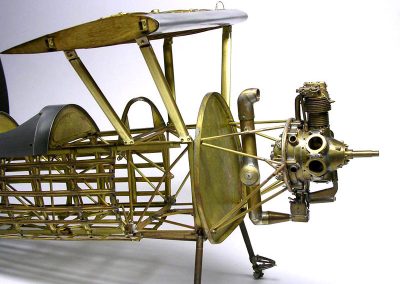

Ken’s 1/15 scale Sopwith Camel includes a second engine on a stand. Note that this side is covered and painted.

Sopwith Camel

A right side view of the Sopwith Camel. This side is left as a cutaway so the interior structure can be seen.

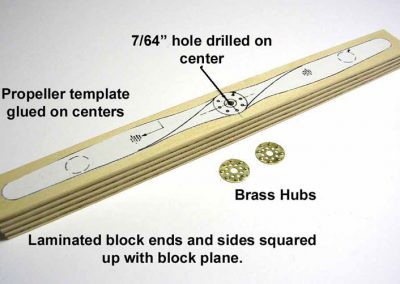

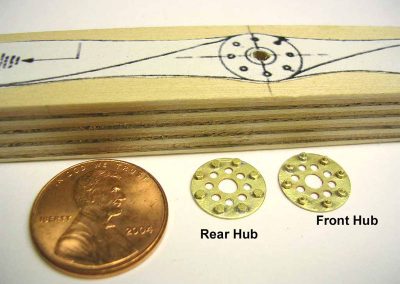

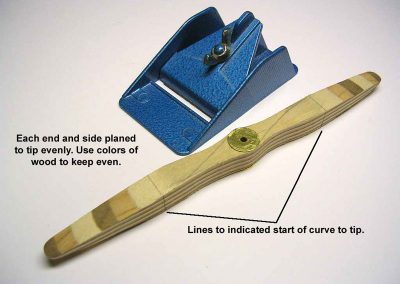

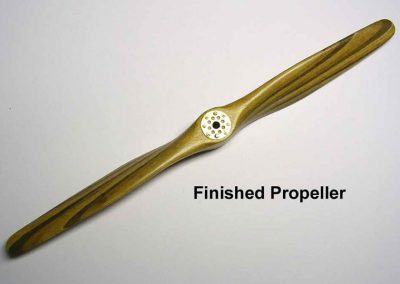

Propeller Construction

The making of a laminated propeller, starting with the laminated block in this photo.

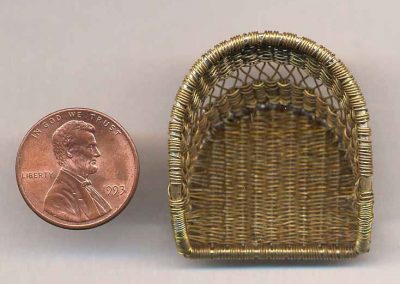

Sopwith Camel Seat

The wicker seat is woven, not with wicker, but rather with fine annealed wire. The effect is absolutely authentic.

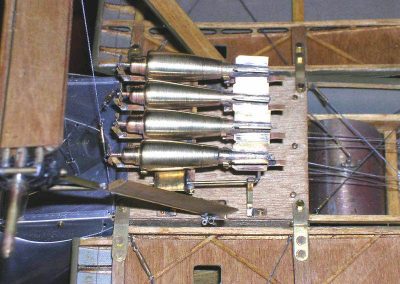

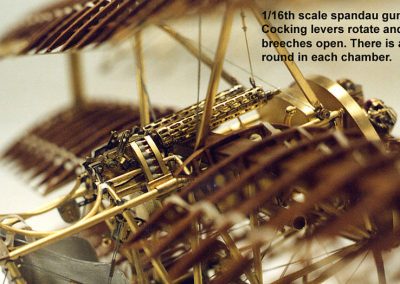

Sopwith Camel With Machine Guns

This photo shows the machine guns mounted on the partially complete Sopwith fuselage.

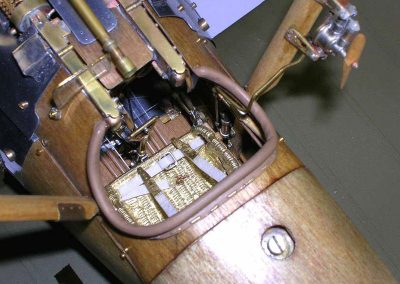

Sopwith Camel Cockpit

This view shows the cockpit from above, revealing the “wicker” seat in place with seatbelts. In the upper right corner of this photo you can see the propeller for the wind-driven fuel pump.

Sopwith Cockpit Control Pulleys

Cables from the cockpit controls run through tiny pulleys. Yes, the controls actually move the wing surfaces.

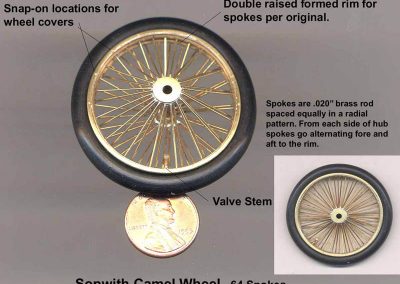

Sopwith Camel Wheels

This photo shows the fine detail in the spokes of the wire wheels. It seems almost a shame to cover all that fine work with the wheel covers shown in the next photo.

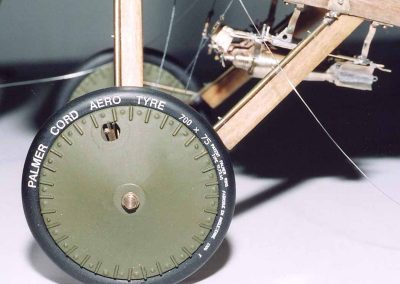

Sopwith Camel Wheels

Here you can see the wire wheels with their wheel covers. However, the other side of the far wheel was left uncovered so that the detail could be seen.

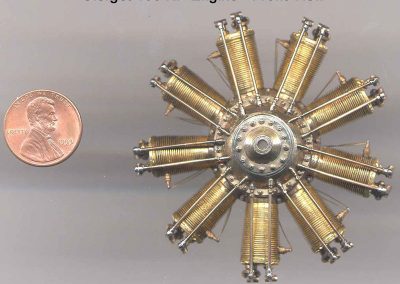

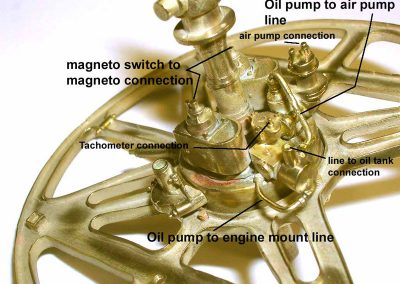

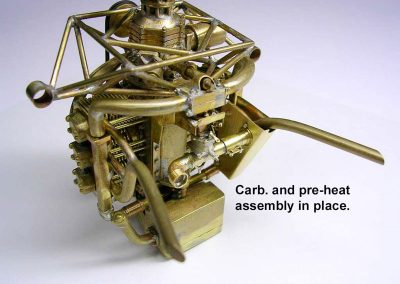

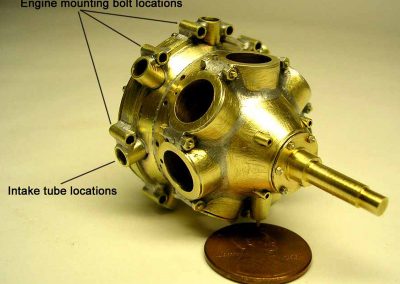

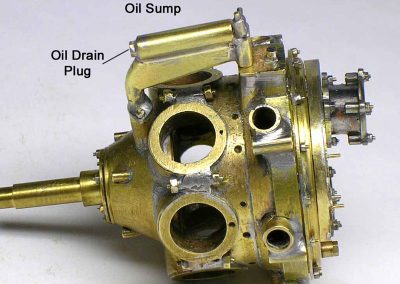

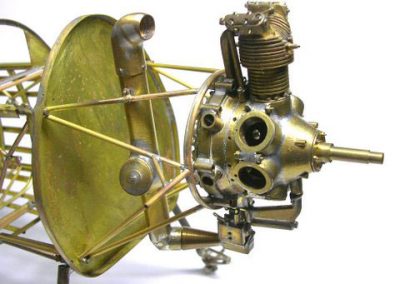

Clerget 130-HP Engine

These photos show details of the 130-HP 9-cylinder radial Clerget engine that powered the Sopwith.

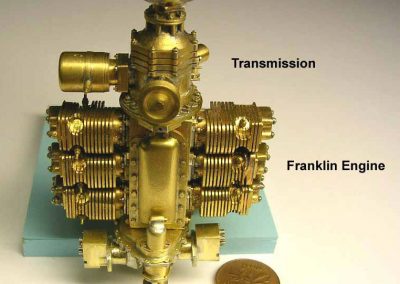

Bell H-13D Souix M.A.S.H. Helicopter

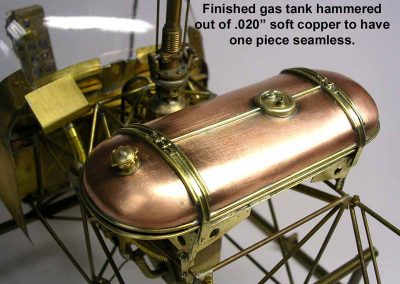

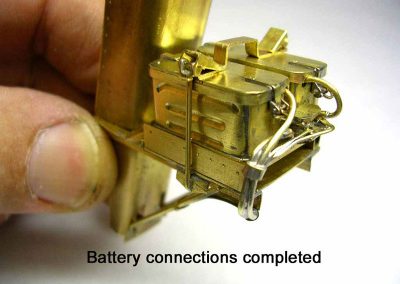

Bell H-13D Gas Tank

The deep curves of the gas tank required the use of softer copper to form its shape. This is another example of Gretchen’s handiwork in miniature metalsmithing.

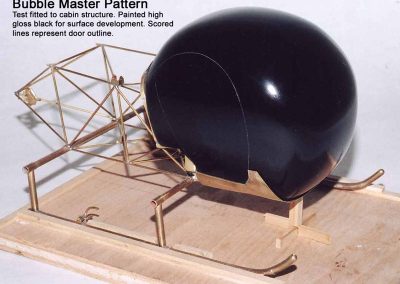

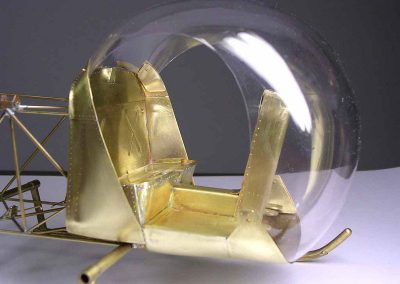

Bell H-13D Bubble Canopy

Making the bubble canopy. First, the shape is carved and painted gloss black so any imperfections show up, and can be corrected.

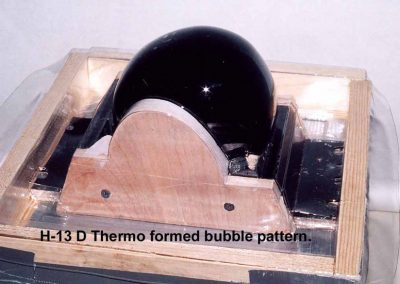

Bell H-13D Bubble Canopy

Then, a vacuum mold is made, and the material is heated and drawn over the form.

Bell H-13D Bubble Canopy

Finally, the edges are trimmed, and the finished canopy is test fitted to the model.

Bell H-13D Instruments

It’s the fine details that make a model like this so fun to admire. Note the instrument faces here.

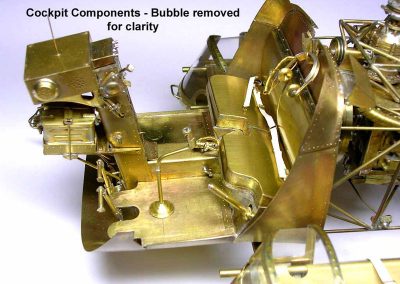

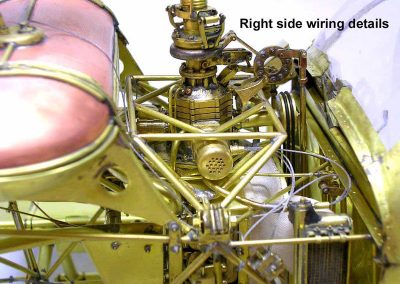

Bell H-13D Cockpit

Here you can see extra details with the pilot’s headphones hanging behind the seat.

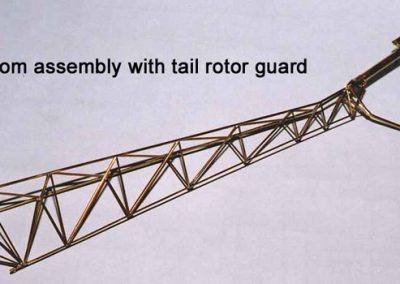

Bell H-13D Tail Construction

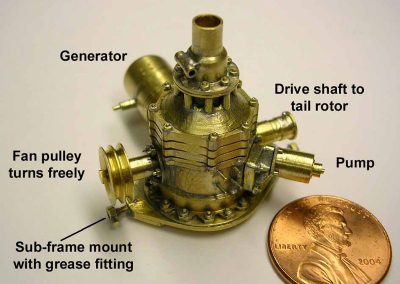

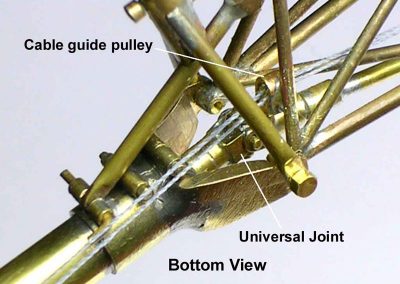

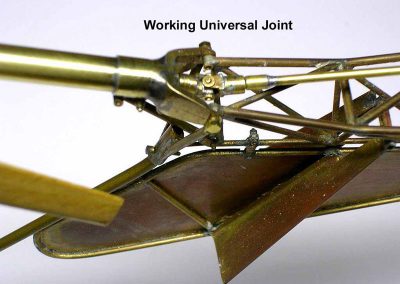

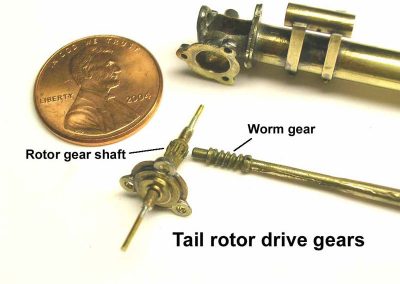

Once connected to the main body, the drive shaft components to the tail rotor are next.

Bell H-13D Tail Construction

Details of the universal joint in the drive shaft to the tail rotor after installation.

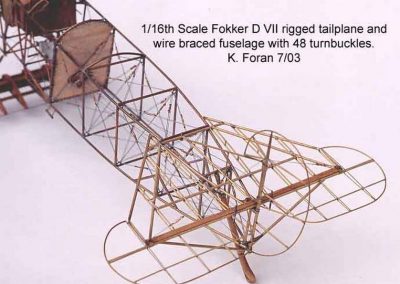

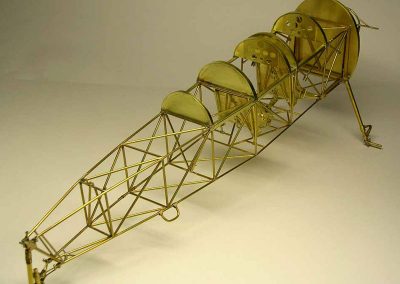

WWI Fokker Aircraft

Ken With His Airplanes

Ken is pictured here displaying two of his models at the 2008 NAMES Expo in Toledo, OH. On the left is the Fokker Eindecker E-IV, and on the right is the Fokker D-VII.

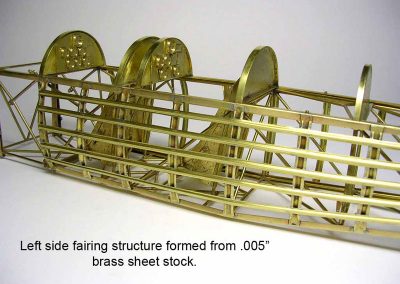

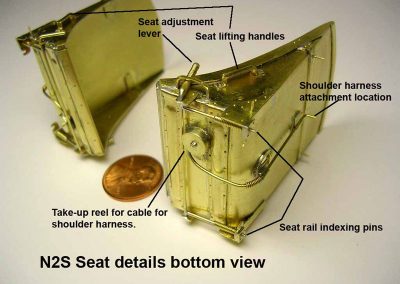

1/15 Scale N2S Stearman Biplane

N2S Stearman Biplane

Ken’s latest project is the N2S Stearman Biplane in 1/15 scale. In this photo the basic fuselage boxed structure is taking shape.

Engine Components

This photo shows many of the other components that will make up the Continental engine.

Continental R-670 Engine

The partially assembled engine with one typical head, and valve assembly attached.

N2S Stearman Biplane Fuselage

The forward part of the fuselage, with the center section of the upper wing in place.

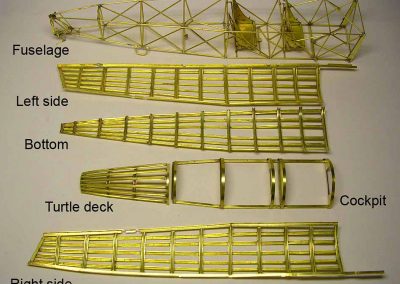

N2S Stearman Biplane Fuselage

The basic fuselage, and the various deck structures that give it a rounded shape.

N2S Stearman Biplane Fuselage

This photo shows the structures in place, with some of the aluminum bodywork around the cockpit also added.

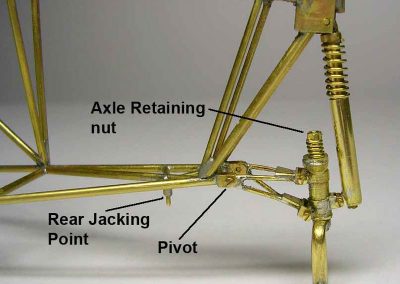

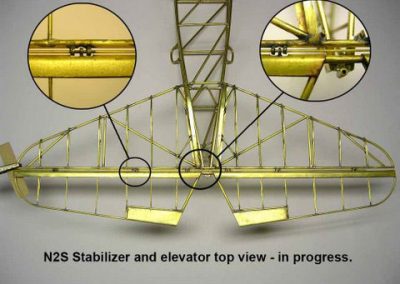

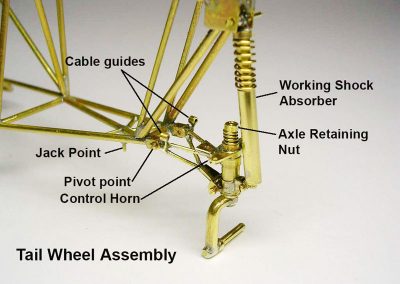

N2S Stearman Biplane Tail Wheel

The tail wheel has quite a sophisticated little shock absorber system, all of which is duplicated in miniature and actually functions.

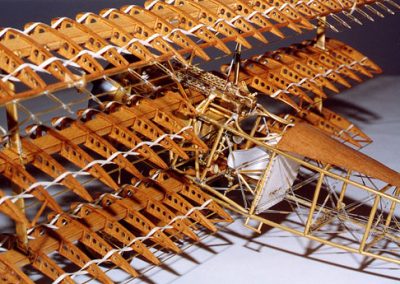

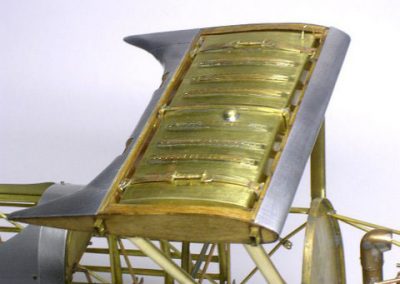

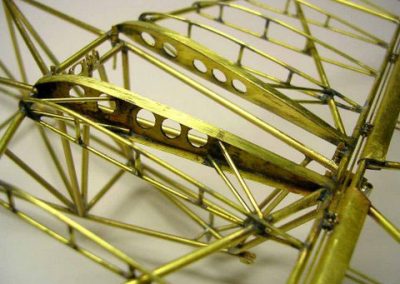

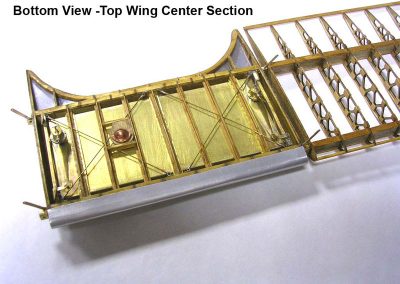

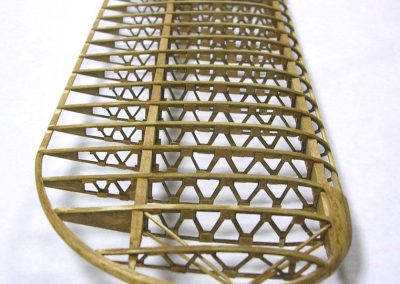

N2S Stearman Biplane Wing

The upper wing sections are nearing completion. Each rib is laser cut, and then reinforcement plates are applied. The leading edge of the wing will be aluminum covered like the center section. The spars have a brass rectangular tube for rigidity, and are laminated with 1/64 scale plywood on the sides and top.

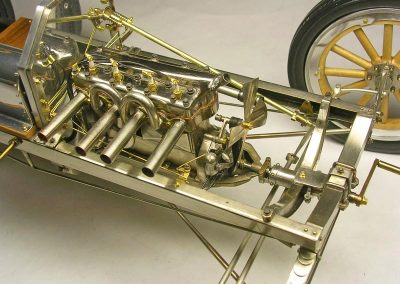

1/8 Scale Ford Model T Board Track Racer

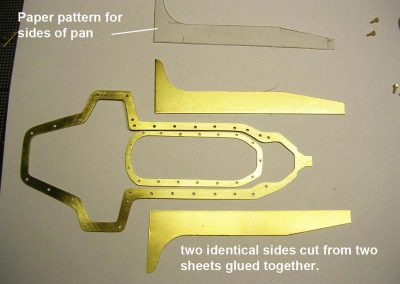

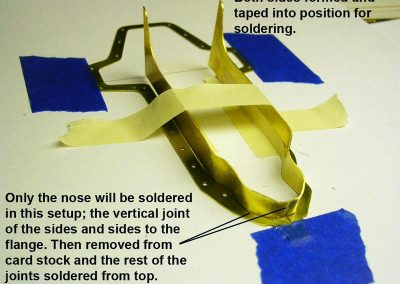

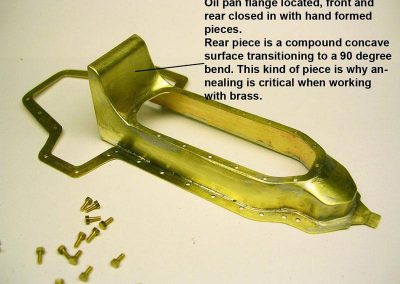

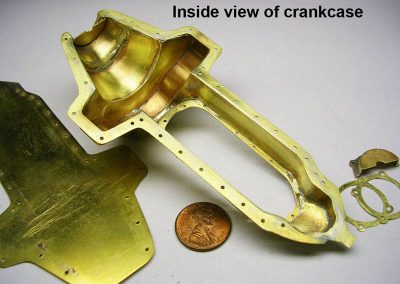

Oil Pan Construction

The following photos document the sequence for making the oil pan from sheet brass.

Oil Pan Construction

The notes that Ken has added to the photos provide some useful information for modelers.

Model T Wheels

The tires are actually made from wood, although once painted satin black they look like rubber. Here you see the tread being applied. If you think there is a quick way to achieve this, forget it. Each piece of the tread pattern is made and glued on individually, before being painted black.

Model T Pistons

A set of four pistons and connecting rods are shown compared to a penny for scale reference.

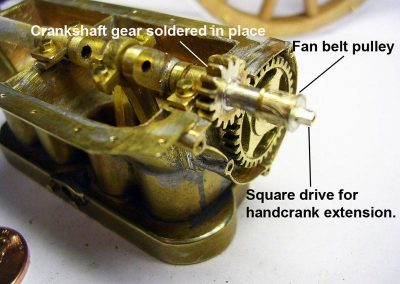

Crankshaft Installation

The crankshaft is installed in the block. This photo shows the connecting rods in place on their journals.

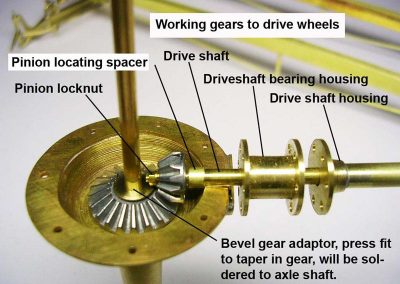

Model T Differential

The differential contains bevel gears that drive the rear axle, just like the real thing.

Model T Transmission

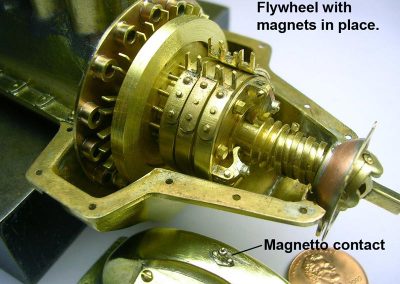

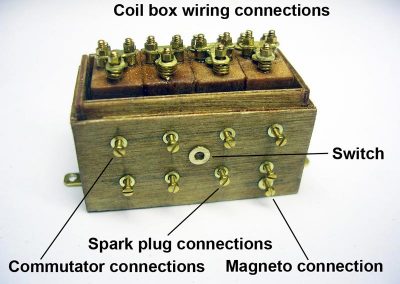

This detail shows the bands on the transmission, and the magnets for the magneto on the flywheel. The magneto contact is shown on the transmission housing at the bottom.

Model T Wheels

The wheels were made using aluminum rims and wooden spokes. The Model T was modern in many ways, but in others it was still using outdated buggy technology.

Model T Engine Block

The engine block with turned camshaft in place. The cam lobes really do actuate the valves.

Model T Trunk

The trunk is made from wood with a framework of brass. In the top tray are some spare parts, but underneath is a hidden battery powered sound module. The module plays the sound of a real Model T, starting up and idling, when a button on the bottom is pushed. The trunk is normally mounted behind the rear axle.

1/12 Scale 1869 Allerton Steam Pumper Fire Engine and 1890 Ladder Wagon

Allerton Steam Pumper

This model was designed and completed to be offered as a kit by Model Expo. This was the first model to be built from the actual kit parts as “proof of manufacture.”