Wooden Crane Mock-Up

This wood and cardboard mock-up shown at the Los Angeles Live Steamers event in July, 1972, was used for confirming the size.

Castings for Travel Base

Sixty-two zinc alloy castings for the travel base. Note the swing bull gear in eight sections.

Drilling the Hinge Pin Holes

Jerry drills the hinge pin holes in the track pads. Since all the holes in 58 castings had to be parallel, this was the most elaborate piece of tooling for the entire project.

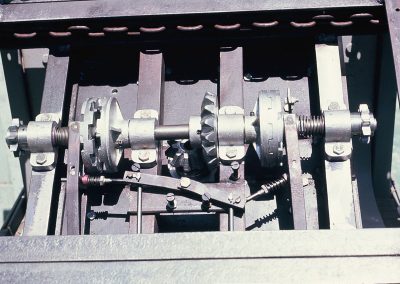

Lower Propel Shaft

This underside view of the lower propel shaft shows the jaw clutches for steering.

Travel Base

A chain hoist is now needed to lift the unpainted travel base while it is set onto the tracks for testing.

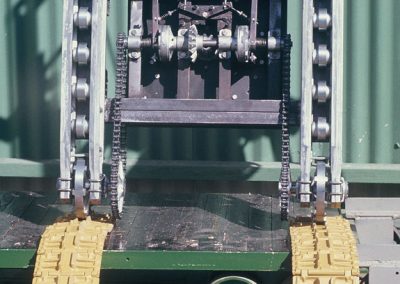

Completed Travel Base

The completed travel base showing a hand crank on the vertical shaft for demonstrating the action.

Welded Frame

A bottom view of the frame shows the four conical rollers, side extensions, and the rear crossmember.

Piston and Rod Parts

The original pistons shown here were made from cast iron. The engine is now fitted with brass pistons with Teflon rings.

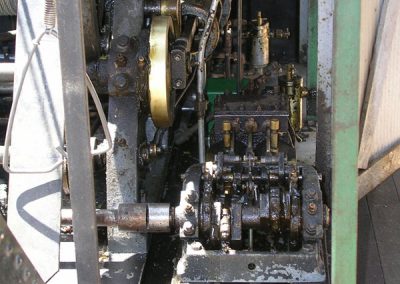

Main Engine and Gearing

By May, 1975 the main engine and gearing were complete, and could propel the machine using compressed air.

Clutch and Brake Drums

The clutch and brake drums with laggings for hoist cables. The dragline lagging is mounted—the symmetrical set is for clamshell work. (All laggings have since been grooved.)

Cross Shafts

The cross shafts for brake and clutch control. Mounting these under the frame was one of the toughest jobs because there was already much in the area where they had to go.

Brass Castings

The brass castings for the steam cylinders (rams) that operate the drum clutches. They are somewhat similar to the power reverse gear on a locomotive.

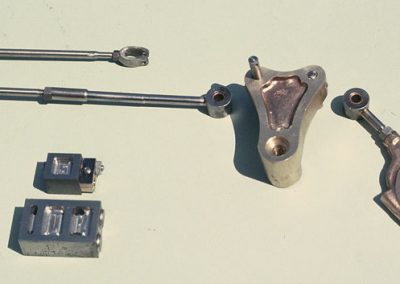

Machined Parts

The machined parts. Surprisingly, with all the guesswork involved, they worked, giving a useful mechanical advantage.

Jerry Testing the Crane

Jerry runs an operational test using 35 psi of air pressure to the engine to pick up a 35 pound load. The tipping point was 5 feet from the center post with no counterweight, an encouraging result.

Boiler Parts

The original boiler parts ready for welding. As mentioned in the article, the rust-prone steel boiler was later replaced with a copper one.

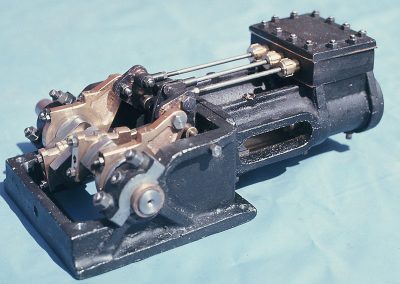

Slewing Engine

The slewing engine departs from full-size practice by using a 2-piece design to simplify foundry and machining procedures.

Boom Sections

The completed boom sections primed for painting. The total length when assembled is 10 feet, which corresponds to 60 feet on the full-size version.

Assembled Clam Bucket

When assembled, a piece of old sash cord was hastily reeved to see what 45 pounds of bucket could do. What it did was break the cord, but not before its digging ability was proved. The seeming paradox of an upward pull making these things dig into the ground is explained by the multiple parts of the closing line, which greatly reduces this force—plus the counterweight and the weight of the bucket itself. Assisted by the rather fierce looking teeth, even this miniature bucket can dig quite respectably in any reasonable soil.

Jerry Working the Crane

Jerry Brown puts the crane to work at the LA Live Steamers steam club meet on Memorial Day weekend in 2007. Photo courtesy of Bruce Ward.