This collection of photos exhibits the range of Iqbal Ahmed’s craftsmanship. His work is even more impressive when considering that he was able to produce these projects with very little consultation from experts, peers, or other resources pertaining to model engineering. He learned much of his craft on his own, and used what would be considered fairly outdated machines. When looking at the breadth of work he has accomplished, it’s clear why Mr. Ahmed was the recipient of the 2012 Joe Martin Foundation Lifetime Achievement Award.

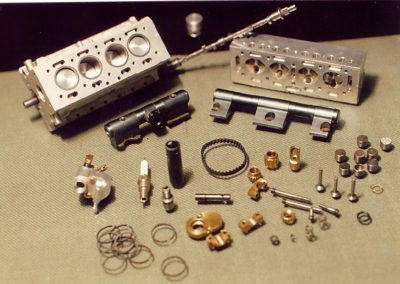

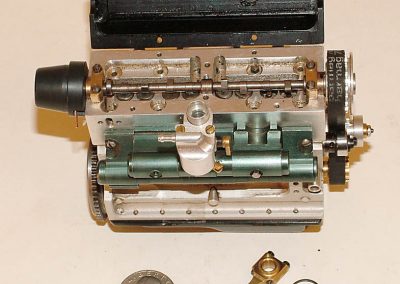

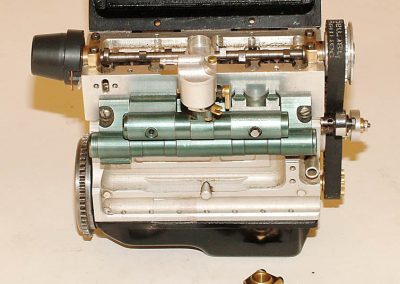

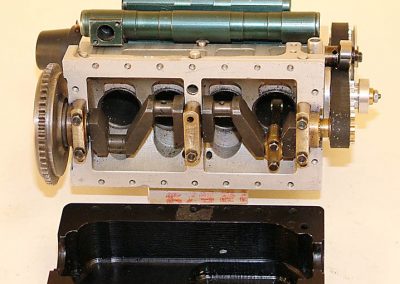

Model 4-Cylinder Internal Combustion Engine

Model Internal Combustion Engine

This is Iqbal’s tiny 4-cylinder overhead cam engine. Seen here is the engine block with pistons installed, and the head removed. The tiny camshaft leans up against the cylinder head.

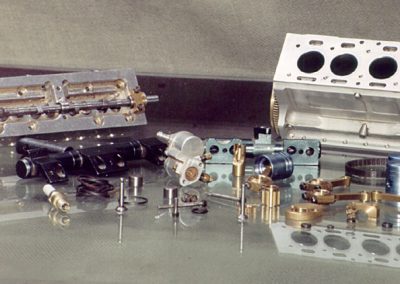

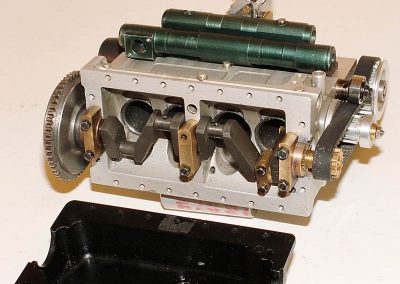

Model Internal Combustion Engine

Another view of the small gas engine shows the pistons removed from the block. You can see connecting rods, valves, and many other hand crafted components.

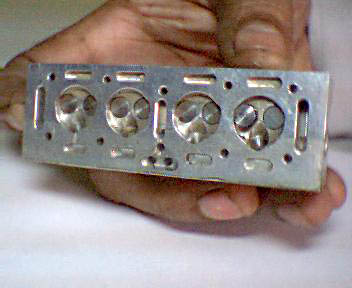

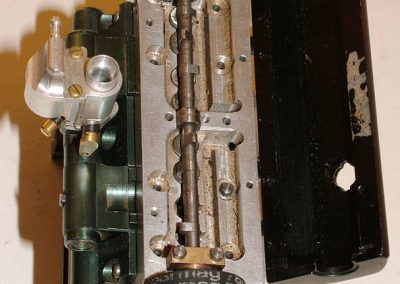

Engine Block Bottom View

An early stage of the engine block. The pistons, crankshaft, and flywheel are in place, but the outside form of the block has not yet been machined.

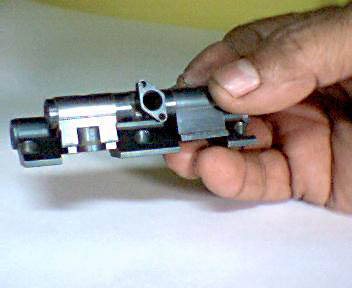

Engine in Progress

Iqbal brought the unfinished engine along on a trip to the Sherline factory in May, 2004.

Engine in Progress

Here the pistons, rods, and piston rings are laid out in the foreground. Amazingly, all the parts were made on a lathe, as at this time he did not have a milling machine.

Engine Block Inside View

With the valve cover tilted up, you can see the single overhead cam shaft and valves. A quarter dollar in the lower left offers scale reference.

Engine Block Bottom View

This view with the crankcase removed shows the crankshaft and bottom end of the engine.

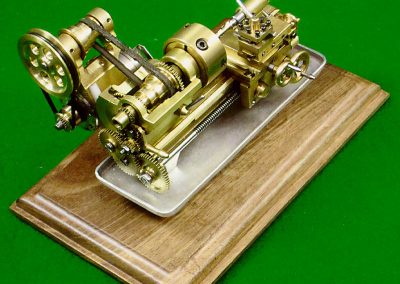

Model Lathe

Model Lathe

A few weeks before the NAMES expo, Iqbal designed and built this lathe as a contest entry for the Sherline Machinist’s Challenge contest. The lathe took 3rd place, narrowly missing 1st by only 26 votes.

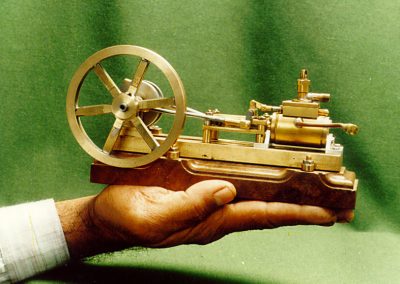

Stationary Steam and Stirling Engines

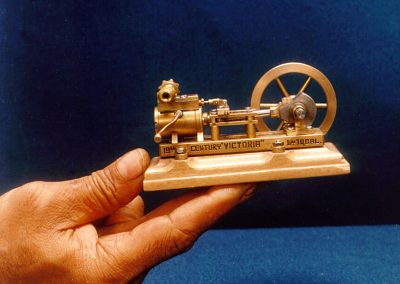

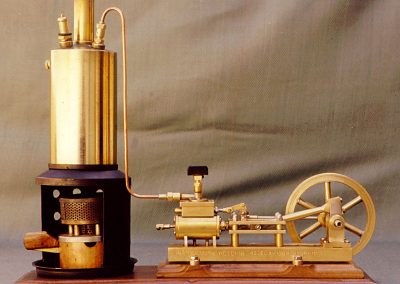

Victoria Horizontal Engine

A small working boiler provides steam power to this very small “Victoria” horizontal engine.

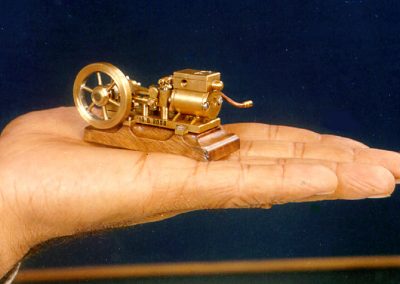

Victoria Steam Engine

The largest of Iqbal’s “Victoria” horizontal stationary steam engines is still relatively small.

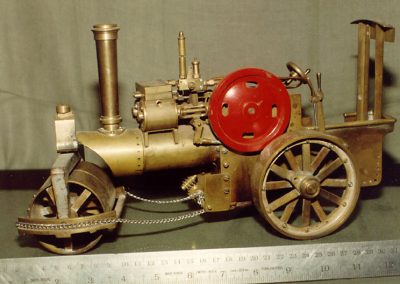

The John Fowler

A 1/16 scale steam powered road roller called the “John Fowler” measures about 14″ long.

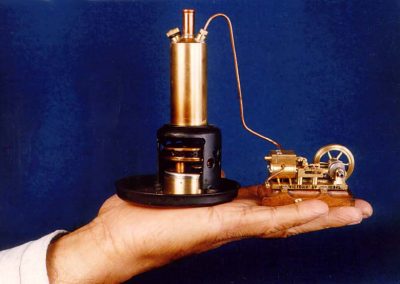

Victoria Engine With Boiler

This view shows the alcohol burner under the boiler, which provides steam power to drive the engine.

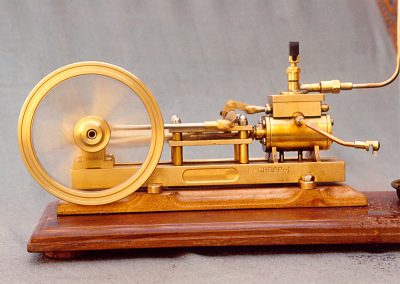

Victoria Steam Engine

A very small vertical engine gets its steam power from a boiler even smaller than the one above. This model was shipped to Detroit and entered in the 2001 Machinist’s Challenge contest, where Iqbal’s work was first seen by an American audience.

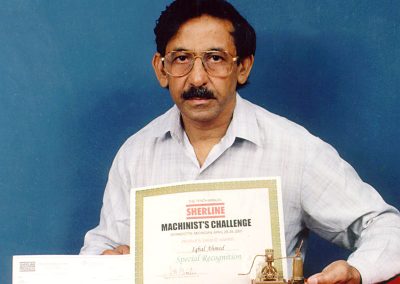

Iqbal With Sherline Certificate

Iqbal received a certificate for his outstanding efforts, and for having the entry that came from the farthest away.

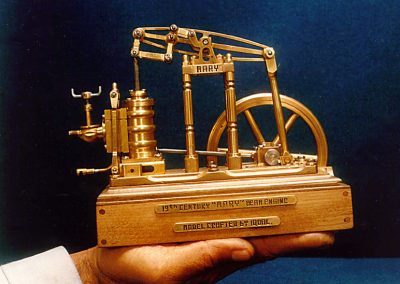

Modeler John Ponsonby With Iqbal

Modeler John Ponsonby traveled from England to see Mr. Ahmed’s engines. Here he admires the “Mary” beam engine. Iqbal welcomes the visit of any model engineers traveling to India, and loves to share his experience in modeling.

Electric and Steam Locomotives

HO Electric Locomotive

Displaying Iqbal’s versatility, this is an HO electric locomotive, track, and signals that he made.

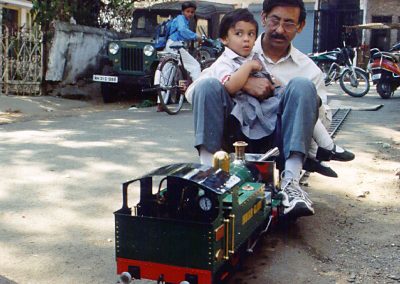

Iqbal and His Granddaughter Take a Ride

Here Iqbal takes his granddaughter, Shahana, for a ride in reverse.

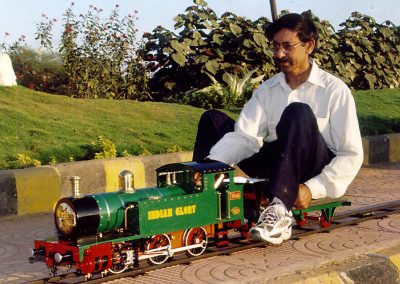

Indian Glory Trial Run

The first trial run with a full load shows the pulling power of this little engine. Five adults and two children are being pulled along.

The Fairy Queen Locomotive

Iqbal says of the Fairy Queen, “I built a 5-inch gauge live steam locomotive. The main feature of this locomotive is that it has been crafted from only a 4 x 6 photograph taken from a full-scale locomotive without any drawings, plans or sketches. I just saw the real locomotive at the Rail museum in New Delhi, India, took the photo, and kept in mind every detail.”

The Fairy Queen Locomotive

The full-scale locomotive is still running with the Indian Railways, and is featured in the Guinness Book of World Records as the oldest running locomotive.

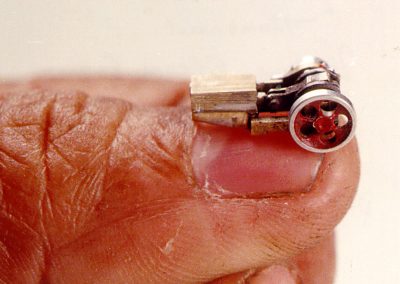

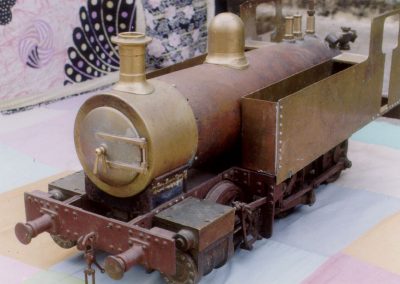

0-6-0 Tank Locomotive

This 0-6-0 tank locomotive is almost completed. Based on a scaled down version of the Indian Glory, shown above, it is a 45 mm scale engine.

The 0-6-0 Engine and Indian Glory

The finished 0-6-0 tank engine is shown in comparison to the Indian Glory, after which it was modeled.

South African Railways Live Steam Locomotive

Lathe Work on Boiler

In the absence of a large milling machine, a lathe was configured to bore holes in the top of the boiler.

Boiler and Steam Cylinders Mounted

The front of the boiler and the steam cylinders are mounted to the locomotive’s frame. This photo gives a good sense of scale.

Visible Heart Pump Demonstration

Mechanical Human Heart Pump

Iqbal said of this project, “A doctor approached me to make a functional mechanical human heart pump mechanism, consisting of a pump piston/auricle and ventricular valves to demonstrate the function of a heart to students.”

Milling for Mechanical Human Heart Pump

With his workshop closed and lathe unavailable due to the poor economy, Iqbal decided to turn out parts in his kitchen using his small Sherline mill. He put it in a horizontal configuration to act as a lathe for making the round parts.

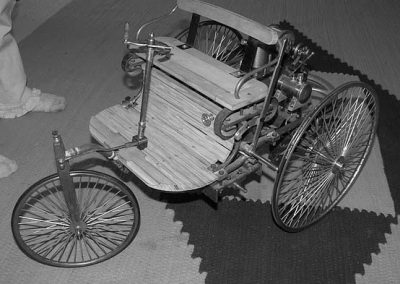

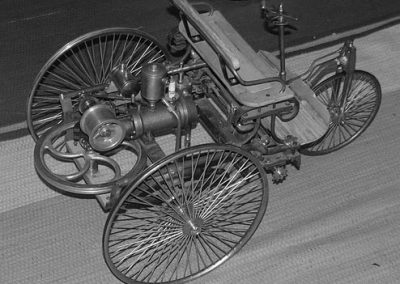

1/4 Scale 1886 Benz Motorwagen

The 3-wheeled Benz Motorwagen was the first application of an internal combustion engine to a motorized vehicle in 1886. The bench seat accommodated two people side by side, and it was steered with a tiller rather than a steering wheel. Prior to this a few vehicles had been powered by steam, but this was the beginning of the end for horse-drawn transportation. The photos below outline in detail the process of building Iqbal’s award winning scale model of the Benz.

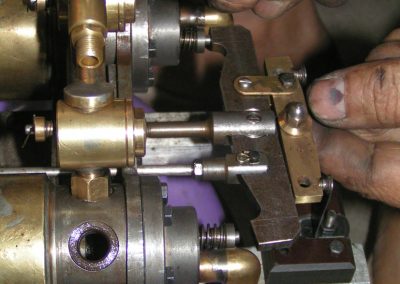

Horizontal Mill Boring

A boring head is attached to a Sherline mill in horizontal position to bore a hole in the side of the engine casting.

Drive Parts and Wheel Hub

Drive parts and a fully spoked wheel hub sit in front of a photo of the full-size Motorwagen.

Assembled Wheel, Engine, and Drive

A wheel with spokes in place next to the assembled engine and drive. Part of a wheel rim is on the right.

Iqbal Milling Work

Iqbal demonstrates the ability of his Sherline mill to make round parts with a special fixture he developed. By rotating the headstock to a horizontal position, he is able to use a cutting tool mounted on a rotary table.

Engine Progress

The nearly completed engine is seen in the foreground, while an acrylic pattern for the flywheel is in the background.

Flywheel Casting

The acrylic pattern for the flywheel casting next to a 6″ caliper gives size reference. The curved spoke shape is a characteristic of the big flywheel on this particular engine.

Engine and Fly Wheel

The engine is mounted onto a test stand, flywheel attached, and is ready for its first test run.

Engine Running

As you can see by the blurred flywheel spokes, the engine is now running. This is known to engine builders as the “first pop”—always an important day for a project like this.

Motor Assembly

The motor is assembled to the chassis. In this photo you can see the leaf springs on the axle as well.

The Finished Motorwagen

This photo of the finished vehicle captures its vintage feel. It could easily be mistaken for a photo of the original in full size.

The Finished Motorwagen

Very few originals exist in full size, but in 1986 on the 100th anniversary of it’s invention, Mercedes Benz commissioned the production of a short run of reproductions.

The Finished Motorwagen

The reproductions can be found in museums around the world, but to our knowledge, this is the only running 1/4 scale model.

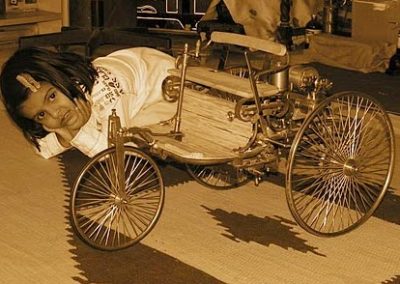

The Finished Motorwagen

A little model looks wistfully at the Benz, but she is still too big to go for a ride.

The Finished Motorwagen

Another shot of the Benz being admired. In the background is a vintage 1944 Matchless motorcycle.

Grand Unveiling of the Benz Motorwagen

For the grand unveiling, a special stage and curtain were prepared.

The Motorwagen With Trophy

The model is seen here with the trophy and a photo of the full-size Motorwagen.

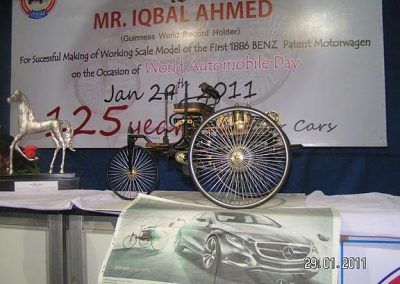

Iqbal’s Award Poster

A large graphic poster was used behind the presentation to commemorate the award.

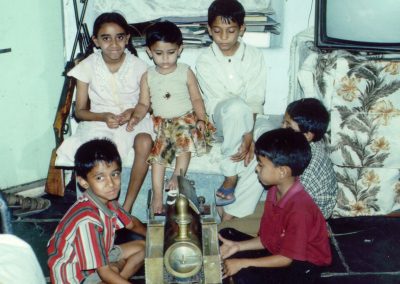

Motorwagen With Friends

The rich oak of the seat harks back to the wagon-making roots of the early auto industry. Our congratulations to Iqbal Ahmed on this outstanding achievement in model engineering.

Showing the Benz at the NAMES Expo

Iqbal displays his model Benz next to the NAMES show poster in 2011.

Iqbal and Arif at Their NAMES Table

Iqbal and his son, Arif, at the table where they displayed their model during the 2-day show.

1886 Benz Motorwagen

The Benz Motorwagen model was given featured exhibit space at the NAMES expo. It was noted as one of the farthest traveled entries in the 22 years that the show had been held.

Flywheel Pattern and Finished Model

Here Iqbal’s son, Arif, holds a pattern from which the cast flywheel was made. Another pattern for part of one of the pulleys is also displayed.

1896 Ford Quadricycle Engine

For some background, Henry Ford was working on a self-propelled vehicle at the same time as Carl Benz . His Ford Quadricycle had four wheels, unlike Mr. Benz’s tricycle layout. However, Mr. Benz put his on the road first. In 2013, Iqbal Ahmed started work on a 1/4 scale version of the engine from the Quadricycle.

Watch a video of the first run of the engine below.

Watch an alternate video of the quadricycle engine.

Watch a video of the finished Quadricycle rollling around a driveway.

Quadricycle Engine

The engine is a 2-cylinder horizontal layout that produced 6 HP in the full-size version.

Quadricycle Progress

Like the slightly earlier Benz, the Ford version uses a tiller type steering arm. However, it’s among the first to apply an internal combustion engine to a more stable 4-wheeled platform.

Quadricycle on Display

The finished Quadricycle was shown at the 2014 NAMES Expo near Detroit, Michigan.

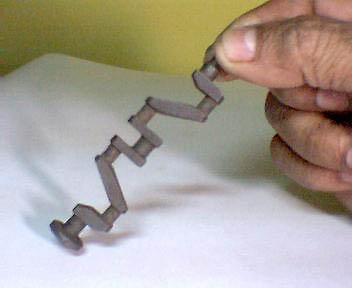

BMW Ignition Component

Iqbal Working on His Lathe

Iqbal making tiny precision parts to get a BMW Ignition switch working. As usual, he’s seen using his large but familiar lathe.

Ignition Component and Parts

The crude silver part is the BMW casting, while the bright brass part is the machined replacement made by Iqbal.

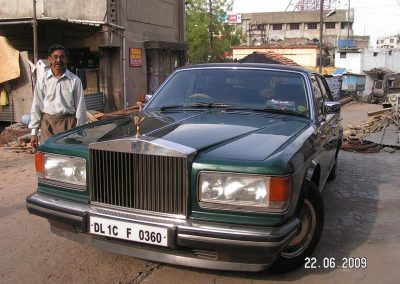

Rolls Royce Ignition Key

Broken Rolls Royce Key and Finished Replacement

A friend brought Iqbal a broken ignition key for a Rolls Royce when he was unable to find a replacement key blank. Iqbal obtained a solid key blank, and using a Sherline mill, he machined the precise splines and grooves to exactly match the broken original. Though not particularly exciting, this is a good example of some of the more practical things that can be done with small machine tools.