Below you can view more photos from Mr. Dahlberg’s Mercer build, along with some other projects. Click on images to enlarge.

Scale Model 1910 Mercer T35 Raceabout

Wheel Construction

Since he started by purchasing the six tires, Ingvar decided to build the wheels first. He made a pattern, and cast the six rims in light alloy.

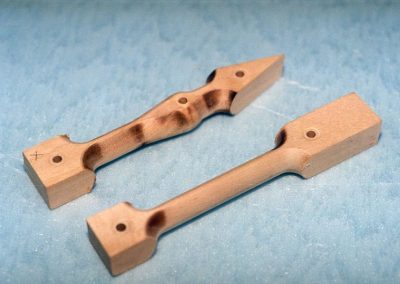

Wooden Spokes

The wooden spokes seen here were made from birch wood. Because the Mercer has no front brakes, the spokes are different on front and rear wheels. The spokes were made using a radius mill on a rotary table.

Milling the Front Axle

The axle has been cast from light alloy. Notice the completed front spring sitting on the right side of the table.

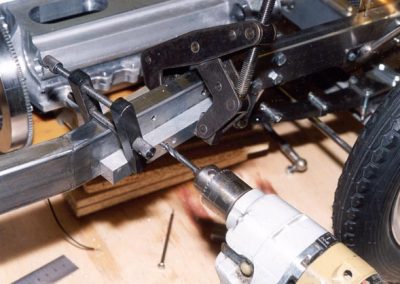

Milling the Frame

The frame is made from 20 mm x 40 mm steel tubing. The forward part was hammered over a 20 mm piece of profiled steel, and then welded to the front part of the frame. (Front springs have been assembled in this photo.)

Front and Rear Axles

Front and rear axles are in place, and the frame sits on its wheels and tires for the first time.

Frame Progression

The frame starts to receive other components, such as the radiator, rear axle banjo (differential), running boards, and rear fenders.

Form Turning

A heavy form was turned from metal, and then the headlamps were formed over it by the process of spinning. Turning the form generated about a wheelbarrow full of chips.

Form Turning

Spinning the 1.5 mm thick brass plate would work-harden it. The plate had to be heated several times to anneal it during the process.

Front End Progress

In this photo, the brass headlamps and radiator have been attached to the front of the Mercer.

The Mercer Dash

The mahogany plywood dash is fitted with instruments (although they are non-functional). The instrument faces were drawn full-size, and then reduced in a photo copier.

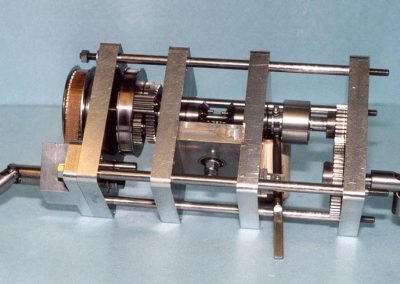

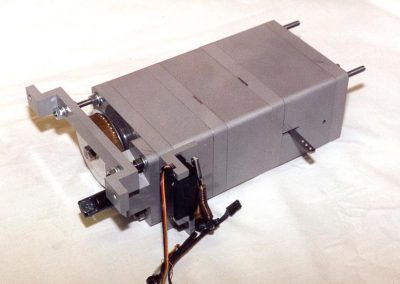

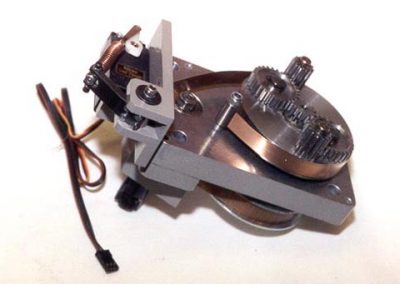

The Gearbox

The gearbox was designed to use a radio control servo, which operates the forward and reverse mechanism. Only one ratio was used, as the car was only operated at slow speed.

The Clutch

The clutch utilizes a strip of phosphor-bronze wrapped around a wheel. This is operated by a landing gear servo. When stretched, the strip softly stops the wheel. Power from the engine is transferred to the forward/reverse part of the gearbox. The gear lever is operated by an ordinary servo motor mechanism.

Differential Housing

The differential housing was made from part of an electric motor case found in a junk yard. The ends were turned from aluminum, and the axle bushings from bronze. The beveled gears were purchased, rather than being handmade. Ingvar did not yet trust his gear cutting abilities for such a critical task.

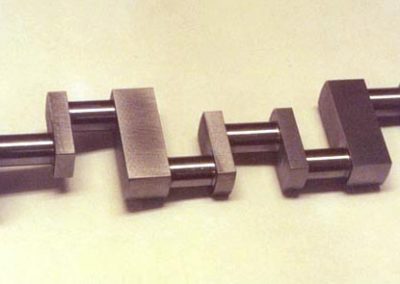

Ingvar Working on the Crankshaft

Crankshaft construction began by cutting a 10 kg (22 lb) piece of steel bar with the band saw. It was then surfaced with a fly cutter. The next step was to use a surface grinder from two 90 degree angles. Then after marking, it was returned to the bandsaw.

Flywheel and Crankshaft

This photo shows the massive flywheel installed on the end of the crankshaft.

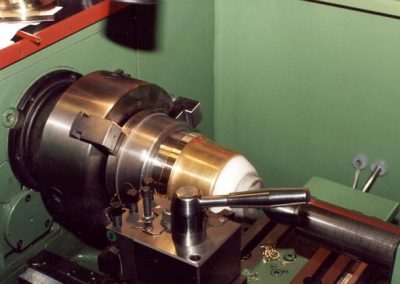

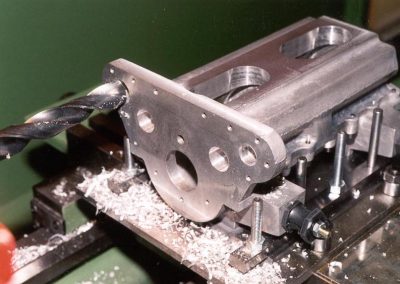

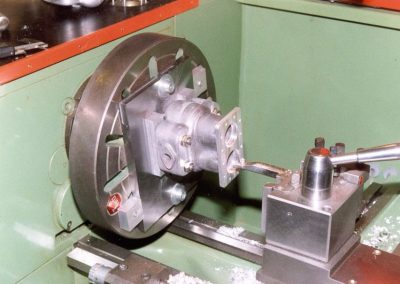

Crankcase Construction

Making the pattern for the crankcase was a unique job. Once cast, Ingvar could begin the process of milling them. The upper and lower crankcase halves were then assembled, along with the gear cover. Next they were attached to the ground baseplate on top of two parallel blocks, and fixed in the lathe. After arboring for the crankshaft, Ingvar then fixed the gearcover, and arbored the front bearing seat. The upper two parallel blocks were then removed so he could bore holes for the camshafts. In this photo, holes are being bored for the distributor.

Camshaft Construction

Instruction from Strictly IC magazine led to the construction of a camshaft grinder. Ingvar attached it to his tool grinder, and made the camshafts from SIS 2940-03 steel. This is a standard Swedish material made for nitro-carbonization, which allowed the camshafts to harden without distortion.

Grinding a Camshaft

A camshaft grinding operation is underway. The engine required two camshafts, but Ingvar made a third for display alongside the finished car.

Casting Cylinders

Ingvar noted that it took one full year to get from the first patterns you see here, to the finished, machined cylinders.

Casting Cylinders

Once the cylinders were cast in metal, the sprues were trimmed off, and the part was ready for machining.

Turning Valves

Ingvar machined his valves from larger preexisting ones, so he knew he was working with the right metal. Pictured here are the original valves from a tank engine that Ingvar started with.

Finished Mercer Engine

Here you can see the original distributor, before it was modified for better performance.

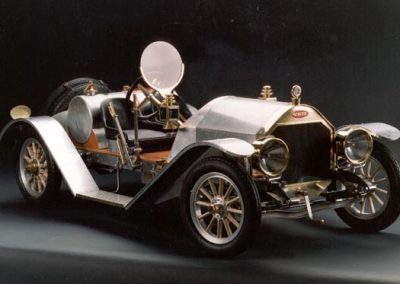

Assembled Unpainted Mercer

The assembled car prior to painting. The raw metal body parts were taken to a plating facility, and given an electroplated finish for protection. The parts were processed alongside production Volvo parts for a modern car, which made for an interesting contrast.

Engine Compartment After Painting

Note the difference between the early distributor design in the unpainted photo, and the more sophisticated double-magnet version that ended up being the final mechanism, shown here.

Final Assembly

Each part was disassembled and painted using automotive quality paint in a professional, dust-free spray booth.

Ingvar in His 1910 Mercer T35 Raceabout

Professional photographer Stefan Svensson composed this photo. He composed this picture using two separate photos: one photo of the model, and the other was a photo of Ingvar dressed in vintage driving gear with his scarf blowing in the wind. The images were blended in Photoshop, with Ingvar’s foot on the throttle, and hand on the steering wheel. Now we all know what it would look like to see Ingvar actually behind the wheel of his miniature Mercer—the perfect conclusion to his 5-year dream.

Other Projects

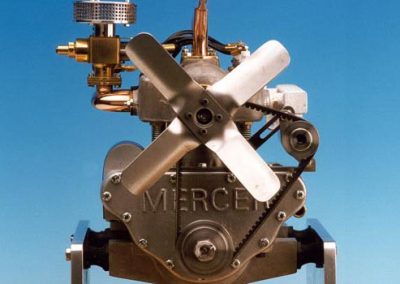

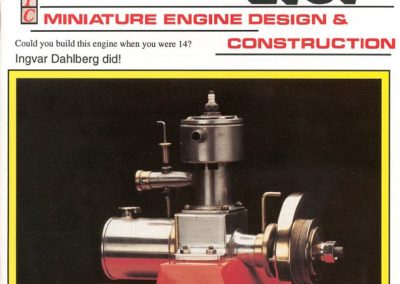

Early Engine

Ingvar got off to a good start early on, building this engine at age 14. It made the cover of the Aug/Sept 1992 issue of Strictly IC magazine!

Early Engine

Regarding the engine, Ingvar said, “I was just 14 years old when I built this 14.3 cc two-stroke engine. It was made with simple methods. The crank-case was cast in a flowerpot with sand. The pattern was as simple as possible. Light-metal from discarded pistons were melted with the aid of a gas-burner, and poured into the mould. The petrol tank was made of a nickel-plated baking powder pot. The engine used to be equipped with a standard contact breaker, a 3/8″ spark-plug, and a standard coil for full-size cars. Nowadays, the engine is run with a glow-plug. All my pupils during 40 years of teaching Physics have seen it run on the teacher’s desk when studying IC-engines.”

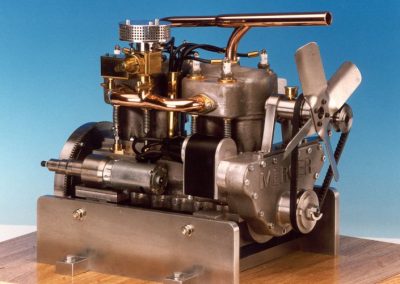

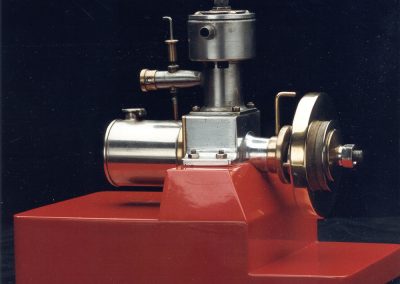

Sea Lion Engine

This Sea Lion engine was designed by Edward T. Westbury, and built by Ingvar Dahlberg. It’s similar to the Seal engine built by the Foundation.

1949 MG-TC Restoration

The 1949 MG-TC that was restored by Ingvar and his son. The design of the post-war MG follows very basic automotive principles, and is not all that different from the 1910 Mercer in many respects.

1949 MG-TC Restoration

Working on this car gave Ingvar the confidence to try building an entire car (in miniature) from scratch.

Supercharged V-8

This 200 cc supercharged V-8 was very close to completion when photographed here in January, 2005.

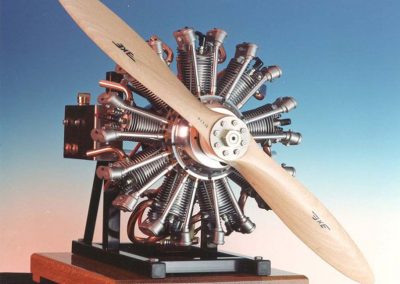

1/4 Scale Wright J5 9-Cylinder Engine

This 1/4 scale model of a Wright J5 9-cylinder aircraft engine displaces 130 cc. The model was designed by the late Karl-Erik Olsryd, and complete drawings have been published in the Swedish magazine Allt om Hobby, and the US magazine Strictly IC.