Below you can view more photos of Harold’s outstanding wooden models. Click on images to enlarge.

Building the Wooden 4-4-0 Steam Locomotive

Wood for the 4-4-0

Wood for each part was selected appropriately for color and hardness. Here is some of the raw stock.

4-4-0 Metal Components

Due to their function in the working engine, certain parts had to be made from metal rather than wood. A selection of some of those parts are shown here.

4-4-0 Components

A metal “boiler” fits inside the wooden shell to contain pressure from the compressor and feed it to the cylinders. The steel shell came from an exhaust pipe for an old car. Valve fittings were made from water line valves.

Building a Wooden Walking Beam Steam Engine, “Mary”

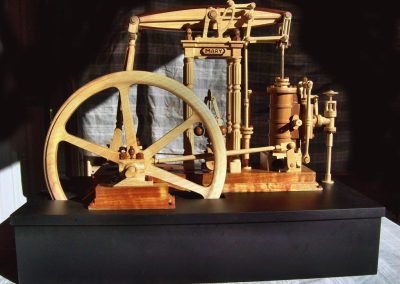

Mary Beam Engine

On June 2, 2009 we received photos and video of a stationary steam engine that Harold built entirely out of recycled wood. This wooden walking beam steam engine is named Mary.

Mary Beam Engine

In keeping with the “recycled” theme, even the drive belt was made from an old boot lace. Several photos of the beam engine were taken by Peter Boyton.

Mary Beam Engine

Harold’s beam engine before final surface finishes were applied. The engine was built based on plans in a book by Tubal Cain, which was gifted to Harold by his son.

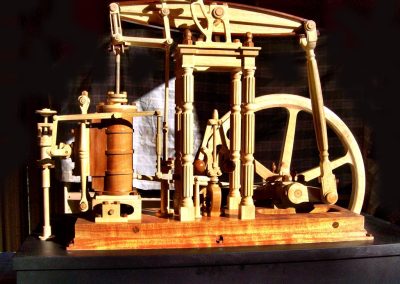

Beam Engine Construction

Harold sent in several photos showing some of the parts in progress during the building of his Mary beam engine. The flywheel is 12-1/2″ in diameter, and was turned from a single piece of wood. Like Harold’s wooden locomotive, the beam engine ran perfectly on the first try!

Beam Engine Construction

Several wooden parts for the drive mechanism. Harold runs the engine on about 12-15 psi of air pressure.

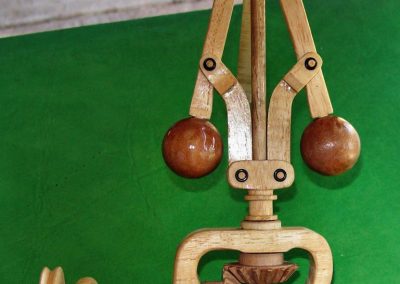

Beam Engine Construction

The governor actually does control the speed quite well, regardless of air pressure.

Beam Engine Construction

The unassembled parts for the flyball regulator mechanism and drive gears. The gears were cut using an indexing setup on the lathe, and have 16 teeth each.

Beam Engine Construction

Drive components were laid out before assembly. Powdered graphite was used as a lubricant rather than oil, which has a tendency to make the wooden parts swell.

Beam Engine Construction

Four fluted support columns. The flutes were cut on the lathe using an indexing setup and a Dremel tool.

Single Cylinder Wooden Steam Traction Engine

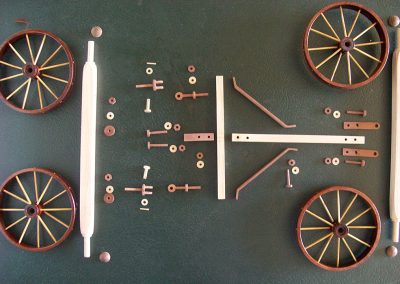

Traction Engine Construction

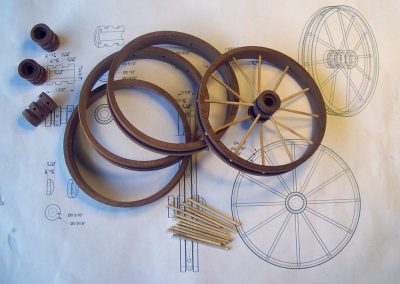

Early construction of the wheels for Harold’s wooden traction engine. First, the spokes were cut using a scroll saw.

Traction Engine Construction

Shaped blocks were glued to the outside of the turned wheel to make the treads.

Traction Engine Construction

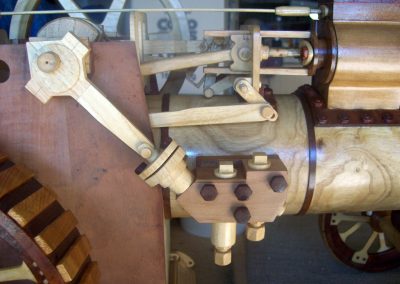

The boiler and smokestack are in place and sitting on the axles and wheels.

Traction Engine Construction

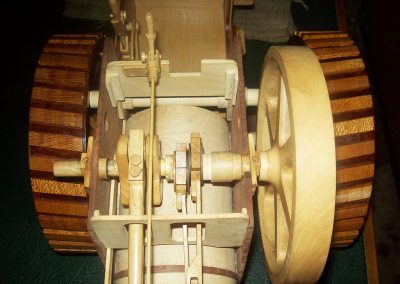

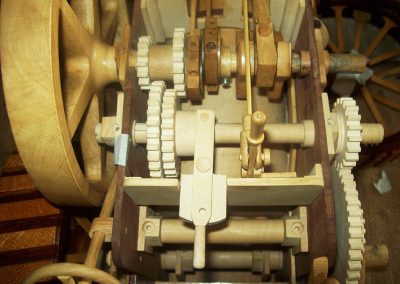

This and the following two photos show the crankshaft and gear shafts from beginning to final assembly. The traction engine has two speeds in forward or reverse.

Traction Engine Construction

Drive gear teeth were cut with a scroll saw using a paper template glued to the wooden gear blanks.

Traction Engine Construction

Wooden lines with hex compression fittings and bolt heads add detail to the mechanisms. Note the many different colors and grains of wood used.

Traction Engine Construction

Harold noted that an excentric on the end of the crankshaft drives the shaft that works the water pump. A lever on the righthand side behind the brake wheel opens the water tap.

Wooden Hay Baler

Wooden Hay Baler

Harold’s finished wooden hay baler model, which is belt driven using the traction engine flywheel.

Hay Baler Construction

The hay is shoveled into this opening, where an arm comes down to compress it.

Wooden Hay Baler

After the hay is compressed, a board comes forward and pushes it into a chute. The hay is wrapped in baling wire inside the chute, and then ejected from the rear of the baler.

Wood Turning and Other Projects

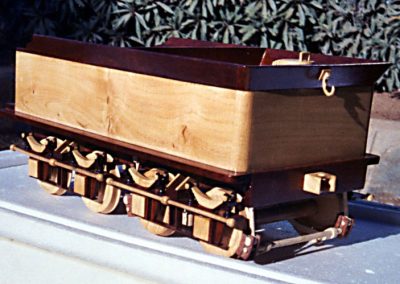

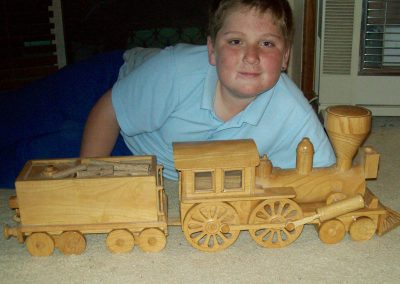

Harold’s Grandson With a Toy Engine

Harold built this toy train engine and tender for his grandson, Alex. It also served as inspiration for his larger working engine.

Wooden Bowl

A wooden bowl measuring 12″ in diameter and 4″ deep. Harold made this bowl from Iron Bark burl.

Wooden Vase

This hollow wooden vase was made from mistletoe, which is actually a parasite that grows on other trees. The unusual coloring is a result of the roots, which grow around the tree branch.

Wooden Clock

Harold made this clock from a piece of Iron Bark burl. The clock is about 11″ x 11″ in size. The face was turned flat on the lathe.