A Former Railroad Employee Builds a Running Model Locomotive From Wood

Introduction

Harold Manwaring, of Australia, spent 7-1/2 years working as a fitter and turner on the railway. After leaving the railroad, he spent the rest of his career driving trucks and other large earth moving equipment. Harold said, “While on the railroad, I did a wide range of jobs. We used to make a lot of tools and worked on many different machines. All of these things I took great pride in doing, and always did the best I could.”

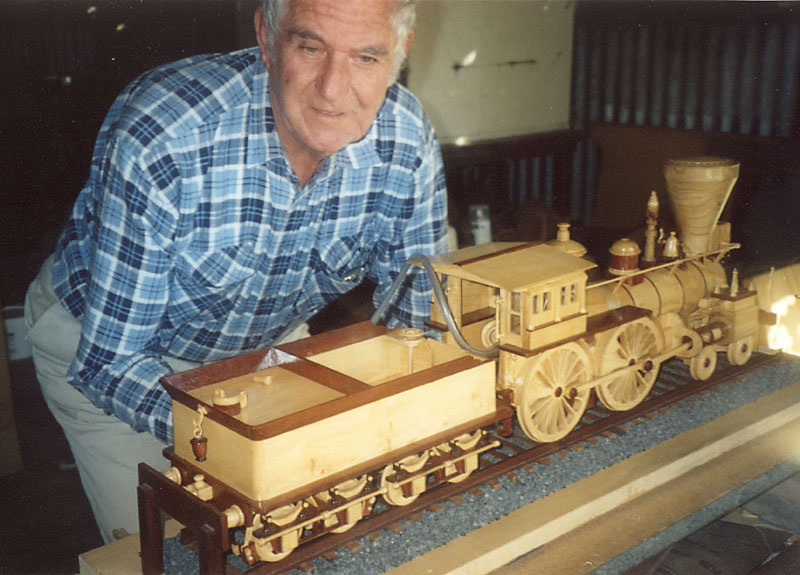

It was around 1997, at age 60, that Harold started turning wood. He made many bowls and other wooden objects, but started to run out of room in the house for these items. So, he decided to make his grandson a simple toy model of an engine. When asked what he would make after that, Harold decided he might try to build one that worked on compressed air. He was quickly told that it could not be done and wouldn’t work. Despite that, Harold took on the project at full steam, and the results are outstanding. His model wooden steam engine consists of 560 separate pieces, and took about three years to make. Harold doesn’t have a computer, so he described his construction of the locomotive in a handwritten letter. He also sent a CD with photos taken by a friend.

Now, Harold first taught himself how to use the woodworker’s lathe, and then built a number of jigs for holding and drilling the wheels and journals. He has displayed the engine on occasion, and entered it into one woodworking show. By 2007, the model engine had run for about two hours and was still working very well.

The working parts were given just enough oil to lubricate them. Even with such an impressive model, Harold’s shop is not a fancy one. It consists of what he called, “an old shed.” He did all of his wood turning and made the steam locomotive model in that shed.

About the Locomotive

This information was included at the request of Colin Kanaley, the curator of the Broadway Museum in Junee, NSW, Australia. He has known Mr. Manwaring for many years, as their rural home region of New South Wales only has a population of 4,000. However, Mr. Kanaley also knows good craftsmanship when he sees it.

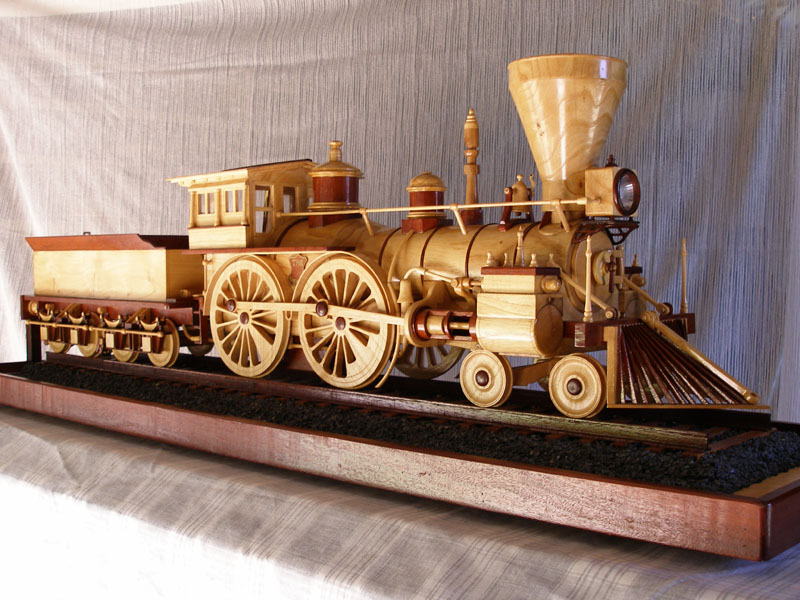

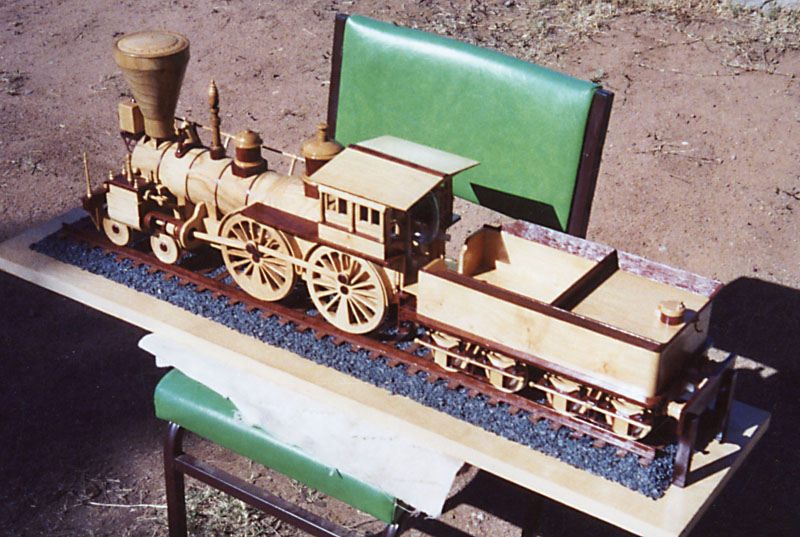

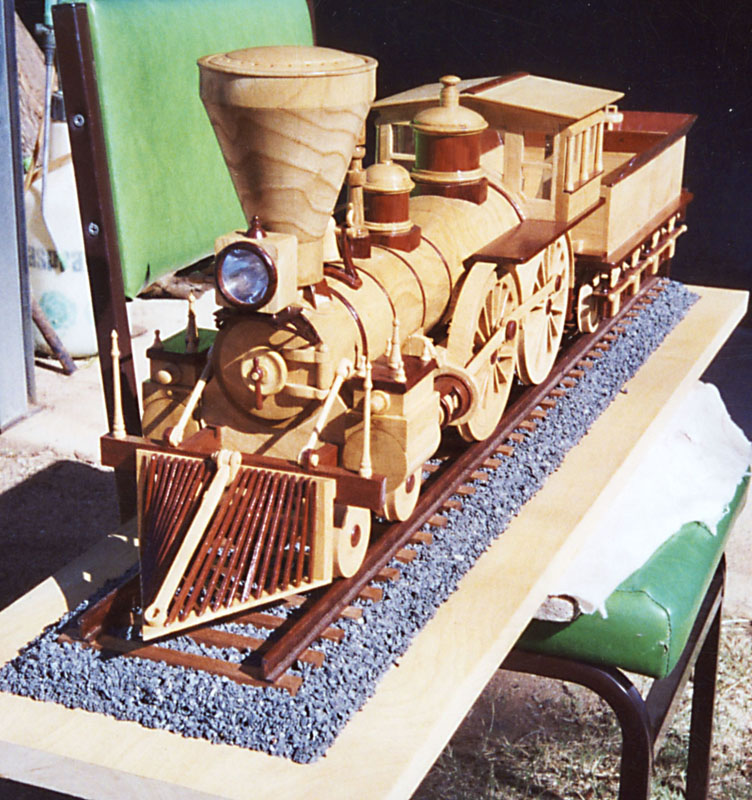

Mr. Kanaley stated that Harold’s beautiful model locomotive is about 3′ long (including tender), and was made entirely from recycled wood (with a few metal parts and pins). Everything works as the loco sits with its driving wheels suspended slightly above the model track.

Air from a compressor is fed into a small stainless steel receiver in the firebox at about 15 psi. Lines to the two cylinders are wooden, as are the cylinders and pistons themselves. The cylinders have a 1-1/8″ bore and 1-1/2″ stroke.

The pistons are fitted with wooden piston rings that are about 1/16″ thick. There are two per cylinder in conventional automotive style. Colin noted, “The engine runs perfectly and exhausts through the stack with a very satisfying ‘chuffing’ sound.”

A close-up detail of the wooden 4-4-0 model. Though we have seen several wooden train models, this is the first one we’ve seen that moves and runs like the original.

Making the 4-4-0 Model

By Harold Manwaring

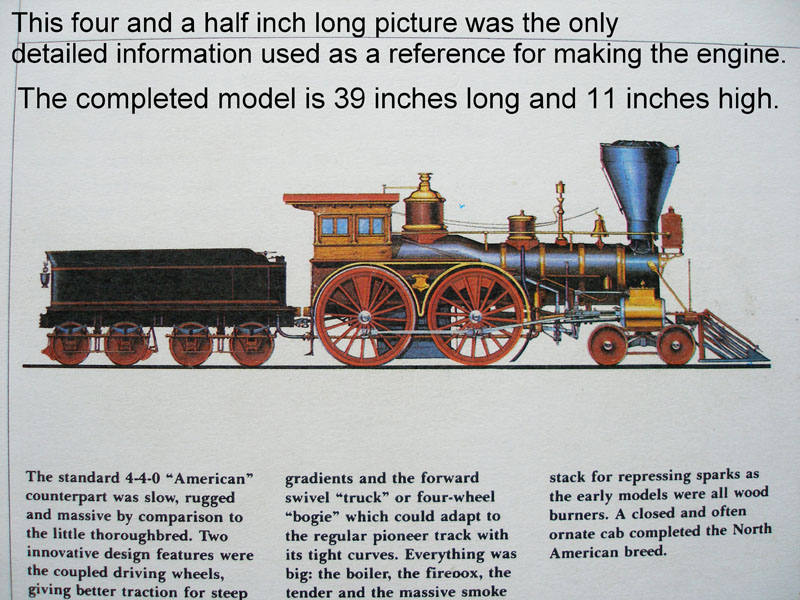

The model is a 4-4-0 locomotive. Henry R. Cambell, chief engineer of the Philadelphia, Germantown & Morristown Railroad designed and built the first 4-4-0 in 1837. This is an attempt by me to duplicate it. I used a print of this engine from a book on steam engines called, Iron Horse, Steam Trains of the World by Peter Lorie and Colin Garratt.

The original print in the book was only 4-1/2″ in size. I used a magnifying glass, and for every 1/64″ I made it 1/8″. The wood and all materials, except the light and reflectors, are scrap materials and recycled. The woods used are as follows:

Desert Ash—an all cream colored wood. It came from street trees that were removed by the Wagga Wagga City Council. It was the main timber used. Desert Ash was used for the cabin, boiler, engine frame, cylinders, pistons, valves, wheels, connecting rods, connectors, and all the air lines. It was also used for the pipes, 1/4″ drilled 1/8″, the right angles, and the tie pieces, 3/8″ drilled 1/4″. For extra strength I used Araldite two part epoxy and PVA woodworker’s glue.

Harold’s model 4-4-0 locomotive is full of small details. The different recycled woods give this model some beautiful coloration.

Red River Gum—Retrieved from an old post and rail fence. It was used for all the red colored timber on the tender, cow catcher, cabin, and boiler mountings.

Olive wood—From our local “tip” (meaning “garbage dump”). It was used for the piston rings, eccentrics and whistle body.

Jarrah wood—From some discarded as scrap I had in the shed. It was used for the spring hangers on the tender, and posts to hold the tender on the end of the rail line.

Australian Red Cedar—From a piece I saved from an old bank that was turned into a residence. It was used for the rail line, three pieces for each rail, and support for the light.

Queensland Maple—From of an old cabinet on the way to the tip, and used for the rail line sleepers.

Osage Orange—Used for the wheel and rod in the door. It was the only timber I could put a thread on.

Also, the steel tube inside the body of the engine was made from two scraps of car muffler tube. The valves I fitted to this tube were made from old water tap spindles. Two ball bearings and two springs came out of a little electric motor—all were turned on the wood lathe. I had to use the closest tolerances possible as compressed air does not expand like steam; however, I also took into consideration humidity and how much the wood would move.

Two air lines run from the cabin valves out to the whistle, and one to the valves. The whistle blows at about 2-3 lbs of air, and the engine runs really well at about 12-15 lbs of air (and stops at 8-9 lbs). It worked on the first attempt, so I stopped and had a beer.

—Harold Manwaring

A Steam Traction Engine From the Pages of Model Engineering Magazine

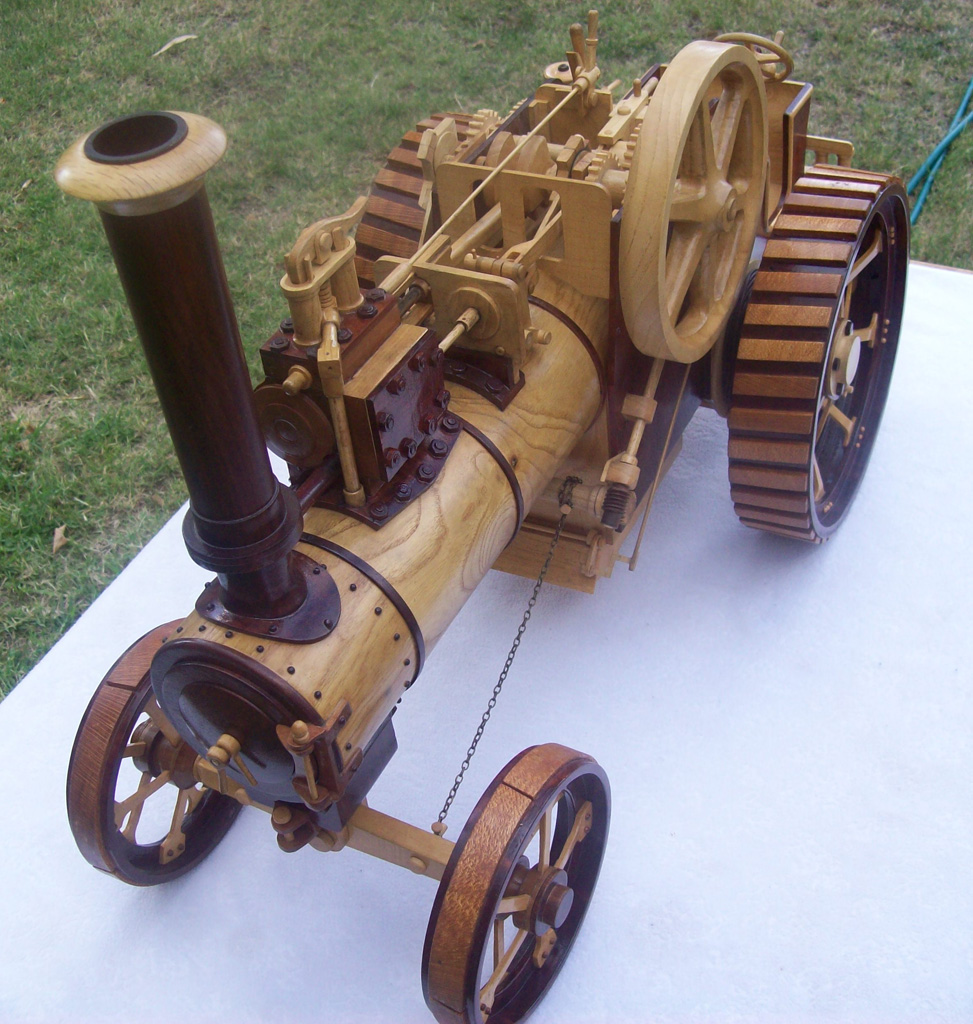

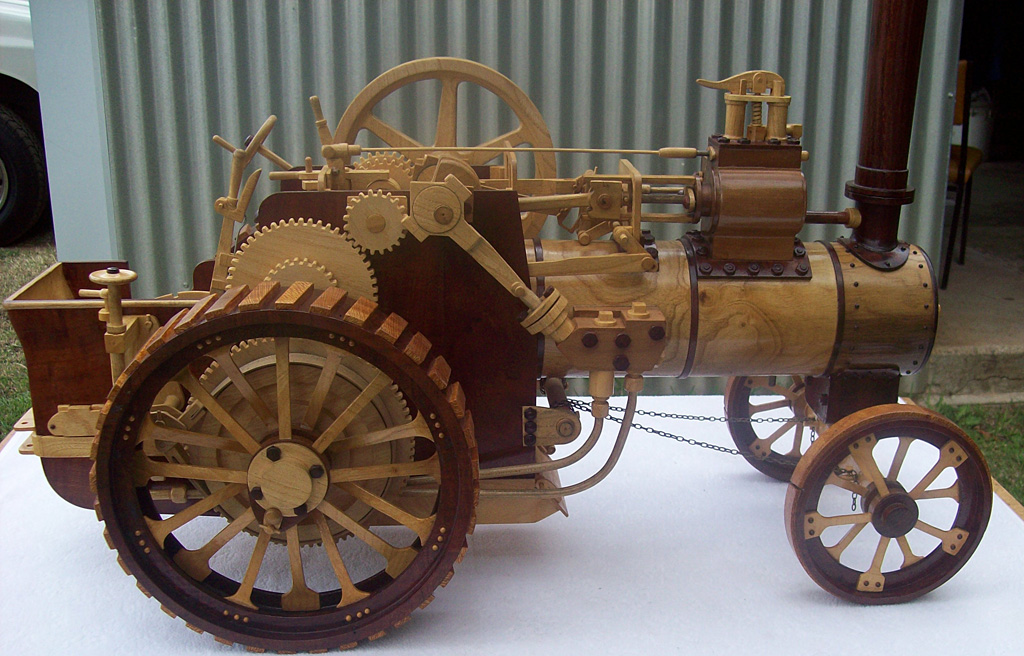

In May 2013, Harold sent a flash drive with photos and video of the construction of his latest large wooden steam project—a working traction engine. More photos of the construction of this impressive model can be found in Harold’s photo section linked at the bottom of this page.

Additionally, you can watch a YouTube video of the traction engine in action. Harold noted that due to medical and personal reasons, the traction engine would be his last big project, but we thank this talented woodturner for sharing his remarkable craftsmanship.

Harold’s more recent project, a functional wooden steam traction engine that runs on compressed air.

The engine specifications are as follows. Length: 27″, width: 12-3/8″, height: 16-7/8″, wheelbase: 15-3/4″. The cylinder bore is 1-3/8″ and the stroke is 1-1/2″. The gear ratios are: Low – 16:1, High – 10:1. Harold made 881 individual parts for this running wooden traction engine model.

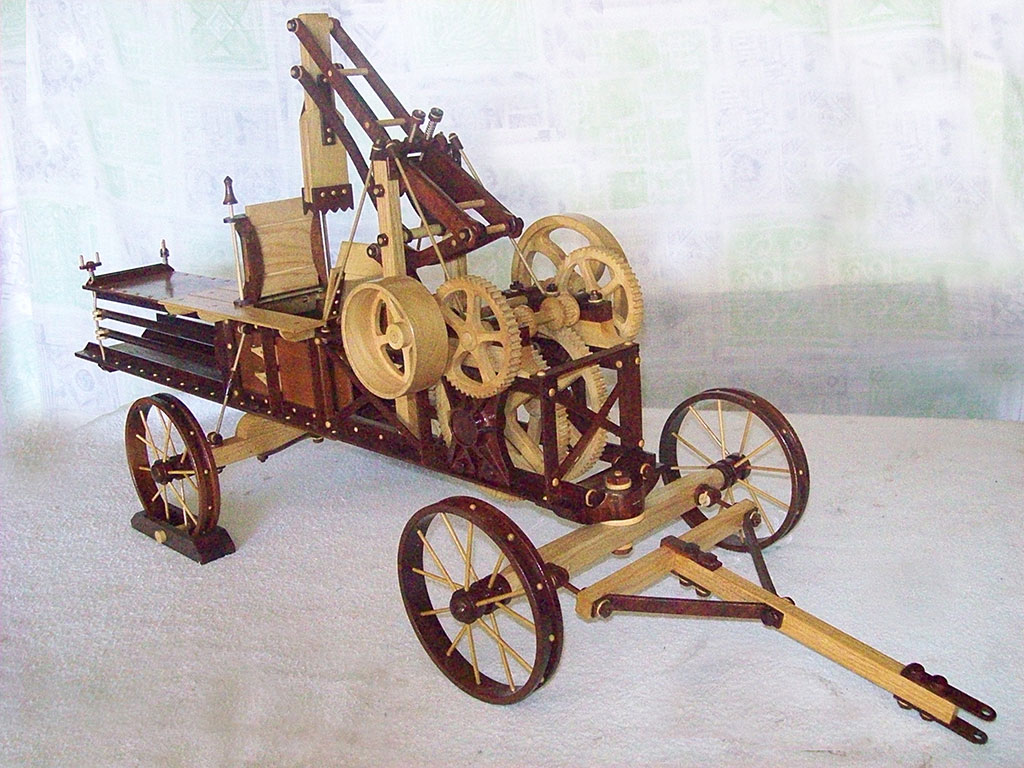

To give his steam traction engine something to do, Harold also built a scale model wooden hay baler. It is belt driven from the traction engine flywheel just like the real version.

Harold’s son, Chris drew up the plans for this hay baler based on those made by the Ann Arbor Hay Press Company starting in 1882. The factory, which was originally located in Ann Arbor, MI, was moved to Shelbyville, IN in the 1920’s. It became a part of the Oliver Farm Equipment Company in 1943, and eventually closed in 1970. Watch a YouTube video of Harold’s hay baler going to work.

View more photos of Harold Manwaring’s impressive functional wooden steam engines.