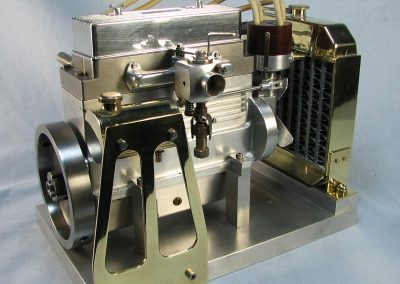

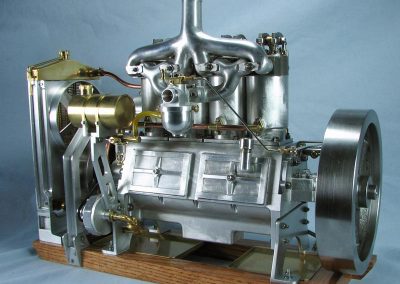

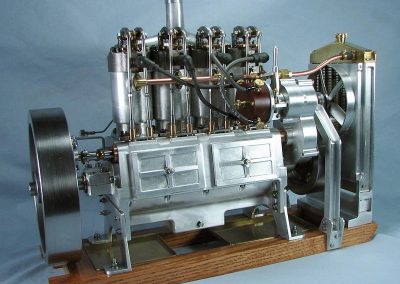

OHV 4-Cylinder Engine

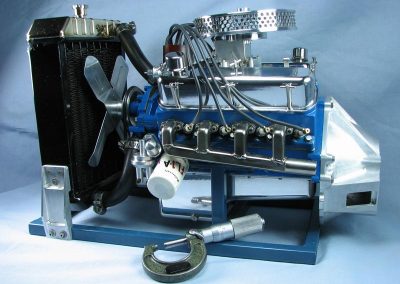

Ford 302 V-8 Engine

Ford 302 V-8

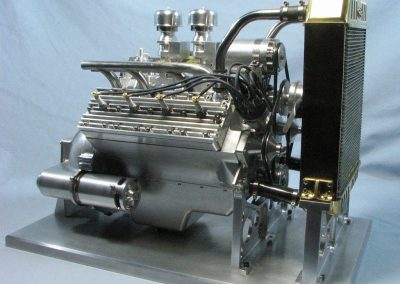

George invested over 2000 hours in this 1/3 scale 302 Ford V-8 engine. The project was started when he was working for the Ford Motor Company.

Ford 302 V-8

The engine has a spark ignition, full pressure oil system, and complete cooling through the block, heads and intake manifold.

Ford 300 Inline 6-Cylinder Engine

George presented this project at the 2014 NAMES show in Detroit—a Ford 300 cubic inline 6-cylinder engine. The engine was started in October of 2013, when George was planning his winter project. The idea came from his inline 4-cylinder engine (the 302 V-8 above) as well as some of the dimensions, bore and stroke. At first, he was only going to add 2 cylinders to the 4 design, but then decided that he didn’t want it to be somewhat generic. So, having worked at Ford Motor Co., he looked at the 300 inline six.

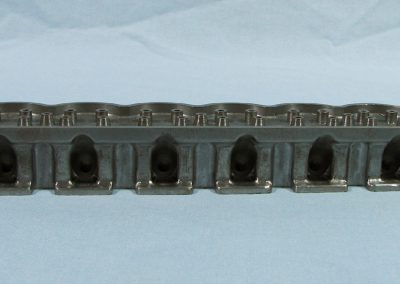

To model an inline six meant that the distributor would have to be mid-engine, and that would require helical gears to drive it. In searching for stock gears there was nothing that would fit the scale of the engine, so George would have to make a set. A contributor on one of the modeling forums came up with a technique for cutting helical gears with a home-made fixture. So, following his plan, George made the fixture and calculated the necessary dimensions for the gears and cutter. Once the gears were cut, he made a small fixture to test the center-to-center accuracy before machining the camshaft. The mesh was almost perfect , so the cam was made in two pieces and the gear was used as a press fit bushing to lock both halves of the cam together.

Finished Engine

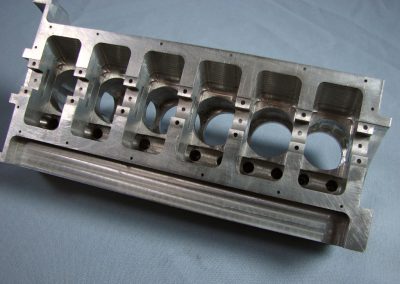

Most of the components are made from 6061 aluminum, while the rest are various metals—1144 steel for the crank, W-1 drill rod for the camshaft, iron for the head, and bronze for the bearings and rods.

Finished Engine

The pistons have 2 iron rings each. The block is water cooled, and has ports drilled so that the water will go through the head and out to the radiator.

Finished Engine

The ignition is of the Hall trigger type, with one magnet in the distributor, and a timing disc with 6 windows.

Finished Engine

George first produced a drawing set that is comprised of 12 sheets in 8-1/2×11 format, drawn in Autocad.

Finished Engine

These last two photos show the engine in running condition, with a radiator and ignition box as seen at the 2014 NAMES show in Detroit.

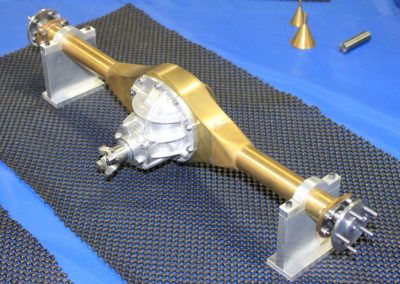

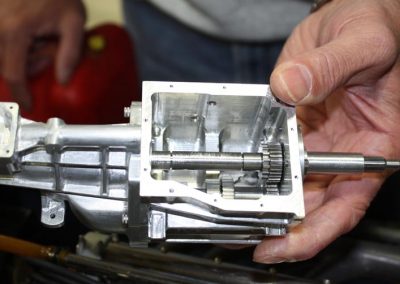

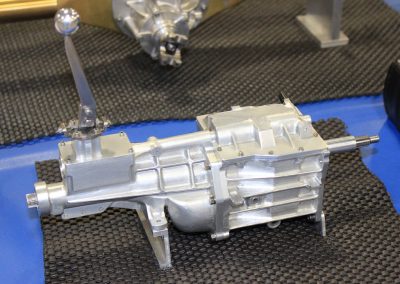

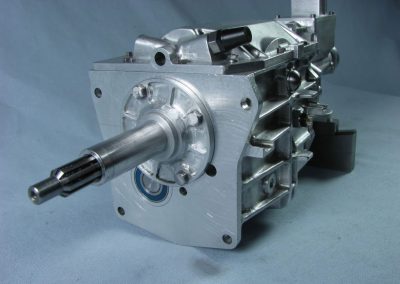

Transmission for Ford 300 Inline Engine

At the 2011 NAMES show in Detroit, George brought along a transmission he was working on for his Ford engine. The case is machined from billet stock using manual machine tools (no CNC), and was coming along nicely at that point.

Various Steam, Hit and Miss, Traction Engines, and More

Associated Hit and Miss Engine

This Associated Hit and Miss engine was built from the late Paul Breisch’s castings.

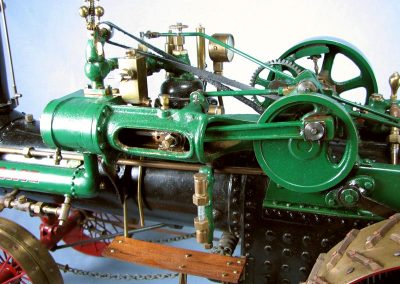

Case Traction Engine

A 1″ scale, 65 h.p. Case traction engine. This was built from the castings that Cole’s Power Model sold.

Case Traction Engine

This was one of George’s first ‘big’ projects. Up until this time he had made mostly Stuart engines.

Case Stationary Baler

This required several trips to Pennsylvania to study, measure and take pictures of the prototype.

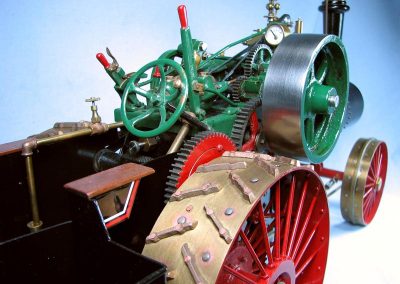

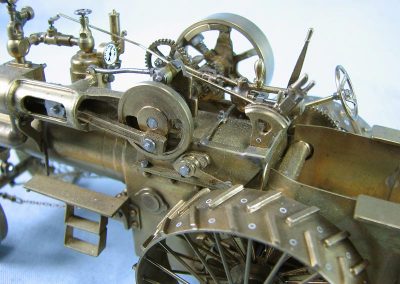

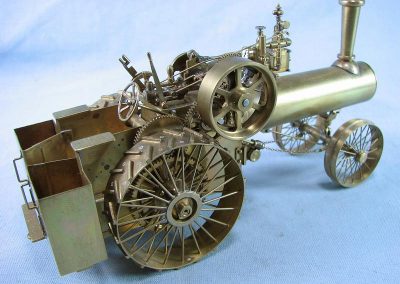

Case Traction Engine

This project was built for the Sherline Machinist’s Challenge contest many years ago.

Case Traction Engine

George took the drawings for his large Case engine and scaled them down to meet the contest requirements of fitting in a 4″ cube, with a maximum length of 5″.

Case Traction Engine

The engine was built mainly from brass, with some stainless and mild steel parts.

Case Water Wagon

This 1″ scale Case water wagon was built to accompany the Case traction engine. George used reference pictures and dimensions from an old Case catalog reprint.

Case Water Wagon

The pump will actually pump water from the tank to the engine. George also made a complete set of drawings for this machine.

Hit and Miss Engine

A small Hit and Miss engine taken from the Little Brother drawings and scaled down. It’s scratch built with the primary parts made from aluminum bar stock. The flywheel diameter had to be increased to give it enough inertia to overcome the compression.

Small Beam Engine

This engine was built from the drawings of the “Mary” beam engine, but was scaled down to meet the requirements of the Sherline contest. It’s built mainly from brass, with stainless steel links and rods. Most of the fasteners are 1.0 x 0.25 mm. It stands less than 4″ tall.

Throttling Governor

A 2″ scale Pickering throttling governor. George had purchased the full-size governor at an engine meet. He hadn’t entered the Sherline contest in a few years, and thought that this would make a good subject.

Throttling Governor

While this was built for the contest, George still wanted it to function, so everything on it operates. The hard part was gauging how thick to make the flat springs so that they would flex and not bend.

Holt Tractor Engine

A Holt tractor engine for which George had purchased plans from Cole’s, but didn’t like the way that it had to be machined. He redesigned the block to be scratch built. Upon completion of the block, he continued to scratch build all of the other parts, except the manifolds and large flywheel.

Holt Tractor Engine

George said, “Once I got it running, I found that it wouldn’t cool effectively, so a water pump, fan and shroud were designed and built.” This engine is one of his largest crowd pleasers at the model shows. People like the way that it runs so slowly.

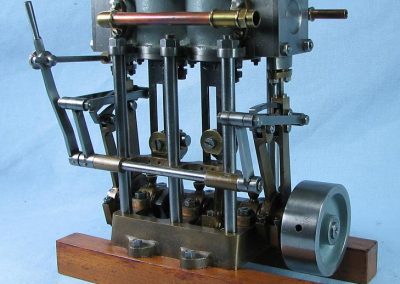

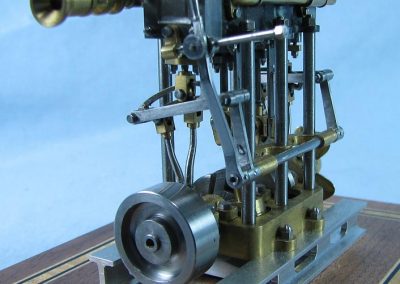

Vertical Steam Engine

This small vertical steam engine with reverse was built for, and entered into, the very first Sherline contest. It’s made mainly from mild steel with 1.0 x 0.25 mm nuts and bolts. It was the only “steam” engine ever to be featured in Strictly IC magazine. The editor, the late Robert Washburn, said he would just call it an ‘external combustion’ engine.

Topsy Turvy Hit and Miss Engine

This Topsy Turvy Hit and Miss engine was scratch built from drawings that were featured in The Home Shop Machinist magazine many years ago.

Mary Beam Engine

Built mainly from bronze, the “Mary” is a beautiful representation of a Victorian style engine.

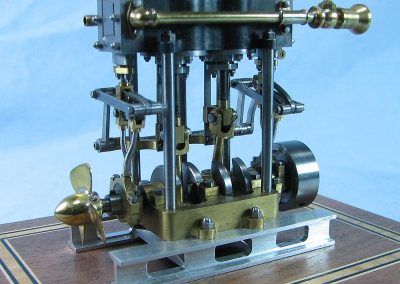

Compound Launch Engine

The castings and plans were supplied by Stuart-Turner. On a compound steam engine, the two cylinders are of different sizes, with the second cylinder utilizing the remaining energy in the high pressure steam after the first cylinder is done with it.

Scale Model Guns and a Model Lathe

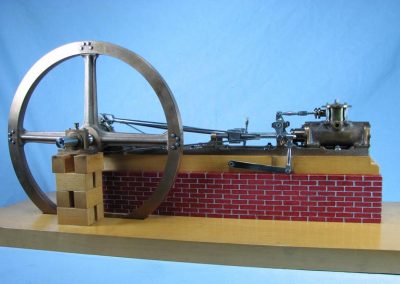

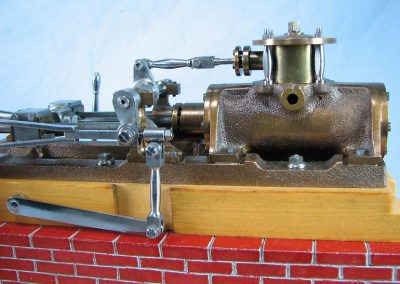

PM Research Scale Model Lathe

This is the PM Research 1/12 scale model lathe. George had seen this lathe at quite a few shows, and had always thought about building one of them, but didn’t get around to it until 2009. It makes a very realistic model, especially when you build the four jaw chuck.

Scale Model Sporting Rifle

This small scale model of a Mannlicher Schoenaeur sporting rifle was made from George’s own drawings.

Scale Colt Army Revolver

This is a ½ scale Colt Army revolver. George took apart a friend’s full-size pistol and made his own drawings to work from.

Scale Gatling Gun

A Gatling gun in about 1/8 scale. George researched this through the public library system, gathering patent information and pictures from books.

1/3 Scale 1953 Ford Flathead V8 (8BA)

George liked to build engines that were not already documented. Being an employee of Ford Motor Company before he retired gave him access to more information than most people. He put over 1900 hours into measuring, drawing, and building this model engine. His first attempts at building resulted in a compression ratio that he felt was too low. So George re-engineered the piston and combustion chamber shapes to get it up to a more respectable 8.5:1 ratio. He also built the radiator. The scale starter and generator are non-functional, but add a lot to the realistic look of the engine.

Real Ford Flathead

Here is a photo of a real Ford Flathead for comparison. Note that the exhaust pipes exit below the heads. George had to re-engineer the exhaust ports to exit above the head (as on the Cadillac engine) in order to be able to machine the water jackets on his block. The block was machined from a solid block of aluminum, rather than cast like the original. This engine also sports aftermarket Edelbrock heads.

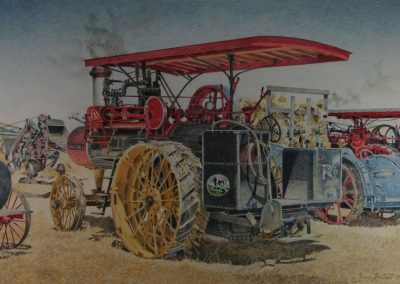

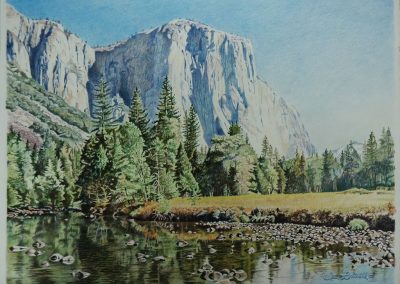

Artwork by George Britnell

George went to art school for a while, but getting a good paying job in that field was tough. So he ended up going for steadier employment to help support the family. It’s too bad, as he is obviously a very talented illustrator. Most of his work was done with watercolors and colored pencils. He covers a wide range of subjects, from people and animals to vehicles and landscapes.