Below you can view more photos of Gary’s engines. Click images to enlarge.

The Stinger 609 Project

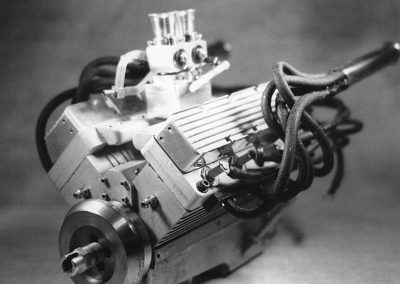

Stinger 609 Engine

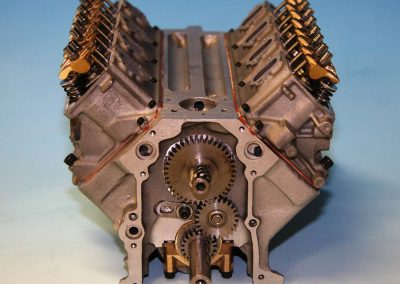

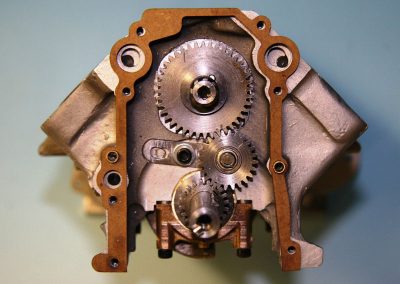

These photos show different angles of the front of the latest generation of new Stinger 609 engines.

Stinger 609 Engine

Several of the components have been redesigned as the engine moves through the prototype stage into the final production version.

Connecting Rod

Originally the rods were cast, but the new billet aluminum rod shown here will stand up to the stresses of the supercharger option —whereas the cast rods would not.

Stinger Oil Ring

Photo 1 shows an oil ring. You can’t just go out and buy oil rings for a piston this small, so they had to be fabricated.

Stinger Spark Plug

The miniature spark plugs were made by Paul Knapp, under the brand name of “Rimfire.” These have a 10-40 thread.

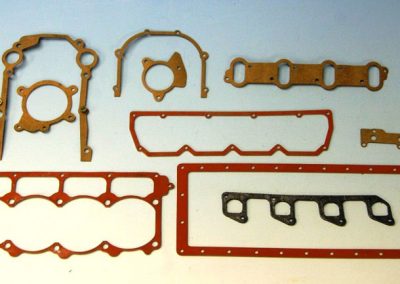

Laser Cut Gasket Set

One of the things you don’t think about when setting about to design a production engine from scratch—a laser cut gasket set.

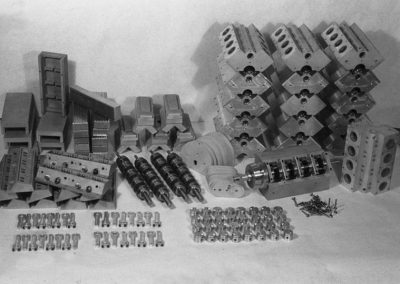

Stinger Block Castings

A group of Stinger block castings sits on the top shelf, while a set of wax blocks are ready for the lost wax molding process to make the next set.

Stinger 609 Engine

A bottom view of the Stinger 609 engine shows the crankshaft in place. This “6-bolt main” configuration is that of a high performance engine, and is a design that can stand a lot of stress. Each main journal has four bolts from the top, and two from the side of the case.

Valve Cover Castings

Parts for the Stinger 609 are made in short run production numbers. These are castings for the valve covers, with the “Stinger 609” and “Conley” name cast in.

Valve Lifters

Sixteen solid valve lifters stand ready for installation. Oil passages in the lifters and hollow pushrods allow pressurized oiling of the upper part of the engine—an unusual feature on an engine this small.

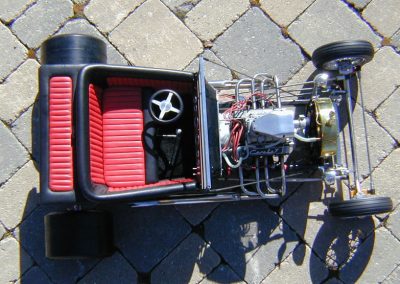

’23 T-Bucket Roadster

The ’23 T-Bucket Roadster makes an excellent showcase for the Stinger engine. (It’s shown here with the old 427 engine.)

’23 T-Bucket Roadster

It features a stainless steel housing for the rear end, powder painted steel frame, oil filled shocks, stainless steel exhaust, front wire wheels, Halibrand style rear wheels with knockoffs, operating headlights, leather interior, carpet, burled walnut dash, simulated gauges, windshield, aluminum firewall, and stainless steel dropped front axle with multi-leaf springs.

Earlier Engines, From V-2 to V-12

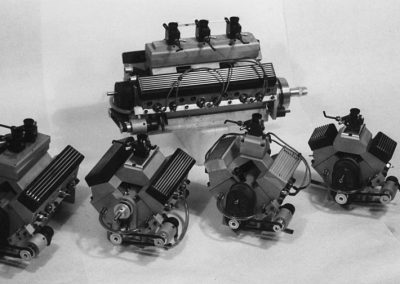

V-2—V-12 Engines

Before settling on the V-8 design, Gary built engines in V-2, V-4, V-6, V-8 and V-12 configurations.

V-2—V-12 Engines

Each engine used the same piston size and other common components, so each was essentially a longer version of the previous.

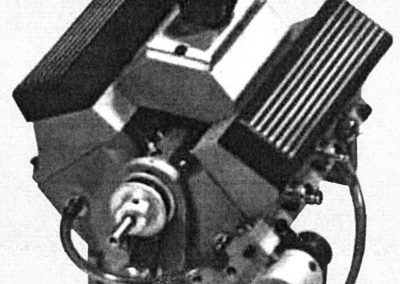

V-2 Engine

Gary’s V-2 engine is shown here without the exhaust headers in place. Only 4 or 5 of these were built. Displacement: .383 cubic inches.

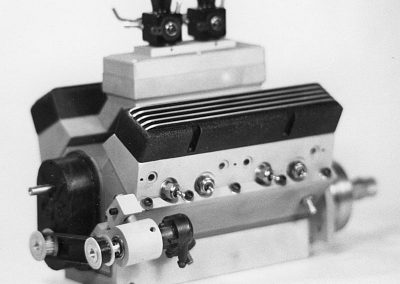

V-4 Engine

The V-4 engine was a more popular design, with 25 being produced. Each engine had a 6.25″ bore and stroke.

V-4 Engine

This photo shows one valve cover removed, and a US Quarter coin for size reference. Displacement: .767 cubic inches.

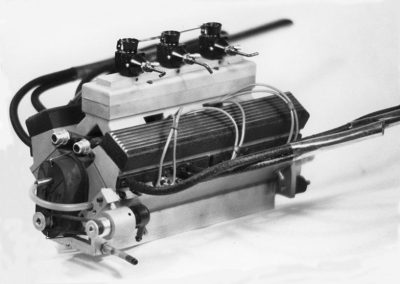

V-6 Engine

The V-6 engine had a single carburetor, but proved unpopular. Only 2 or 3 were made. Displacement: 1.15 cubic inches.

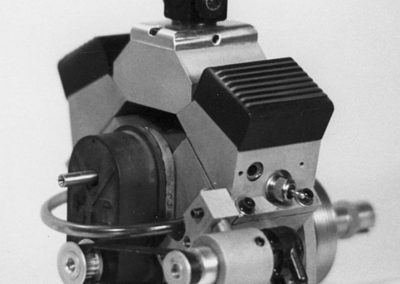

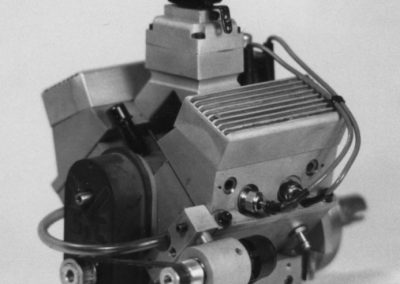

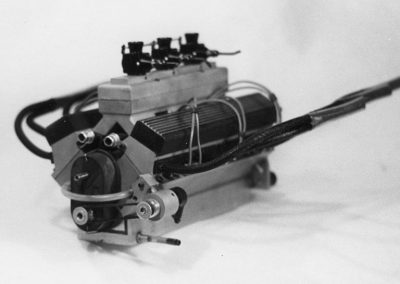

V-8 Engine

The V-8 was the most popular engine design, no doubt due to its similarity to popular full-size automotive engines. Displacement: 1.53 cubic inches.

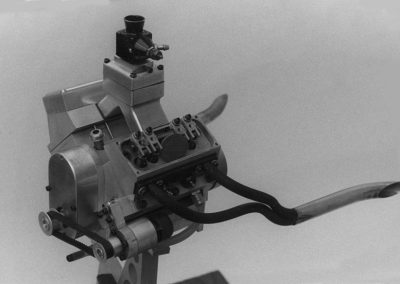

V-12 engine

The V-12 engine sports three carbs and long exhaust pipes. Displacement: 2.30 cubic inches.

V-8 Engine

This version of the V-8 is shown with a “bundle of snakes” type exhaust system. This was the first bar stock V-8 Gary ever made, and it included a full spark plug ignition system. It now resides in a collection in Germany. It was built in the 1980’s.

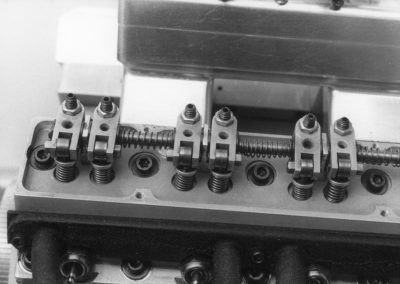

V-8 Engine Details

Pictured here are the V-8 engine’s machined rocker arms with roller tappets and angled glow plugs.

The Viper V-10 Engine Project

Viper V-10 Prototype

The Viper V-10—a project cut down after years of work by an unfortunate fire at the foundry where all the patterns were stored. Here is the prototype ready to run.

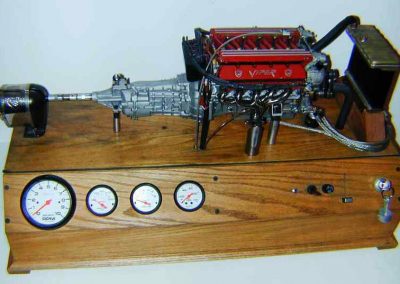

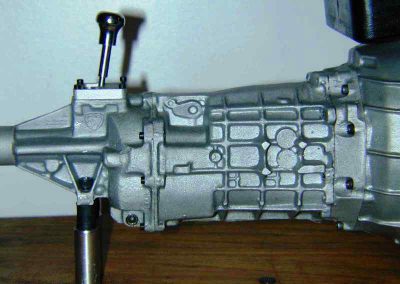

Viper V-10 Engine

A finished Viper V-10 engine and its engine stand. The gauges measure RPM and other vital engine temperature and pressure functions.

Viper V-10 Engine

At the left end is a pencil sharpener driven by the transmission. It’s probably the most expensive and powerful one in existence! In first gear it can grind an entire #2 pencil into sawdust in a matter of seconds.

A Pocket Chopper With a Conley “427” Engine

Pocket Chopper

What do you do with a miniature 5 hp V-8 engine? Build a chopper around it, of course!

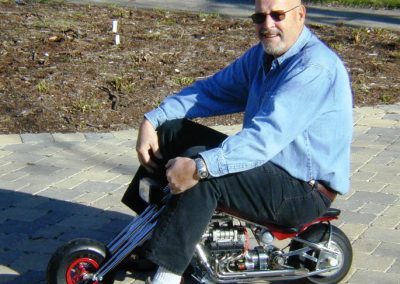

Gary on the Pocket Chopper

Here are some detailed shots of the mini-chopper, seen here with Gary aboard. It utilizes the older style V-8 engine.

Pocket Chopper

These photos of the chopper show the fine workmanship that goes into all of Gary’s projects.

1/4 Scale Top Fuel Dragster

Top Fuel Dragster

The Top Fuel Dragster made it’s debut at the 2006 Toledo Model Show. It was developed to showcase the new Stinger 609 engine. It’s almost 8’ long, 17” wide, and 21” to the top of the rear wing. The car demands attention!

Top Fuel Dragster

The dragster looks like the real thing until you see it compared to a full-size car.

1/4 Scale Dual Axle Vehicle Trailer

Scale Auto Trailer

Gary’s Bucket T Roadster sits atop the scale auto trailer. The trailer includes loading ramps, full suspension, and made an excellent display stand for a 1/4 scale R/C car. Unfortunately, there was insufficient demand for them, so production was stopped.

Gary’s Toys

The Tryon Viper

Gary’s friend Rick Murphy designed this unique looking trike called the “Tryon Viper.” Anywhere he went it drew large crowds. After taking it on a four-hour road trip to visit his brother, he said, “You cannot imagine the CB conversations on the highway.”

The Tryon Viper

It was great fun, and Gary misses all the attention. It was the only one in the entire Chicago area. For five years it was his daily driver, and was one of only five made in the late 1980’s.

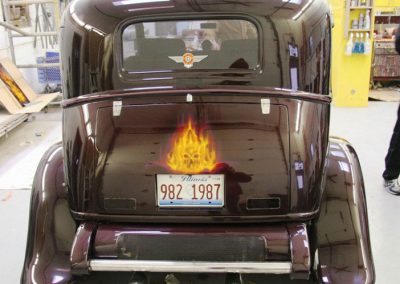

’32 Ford Vicky

This only slightly more conventional hotrod, a ’32 Ford Vicky, eventually replaced the Tryon as Gary’s daily ride.