Below you can view more photos of Find Hansen’s scale model hot-bulb engines, as well as his Diesel engine project.

Hot-Bulb Engines

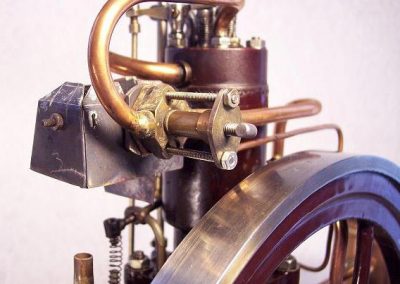

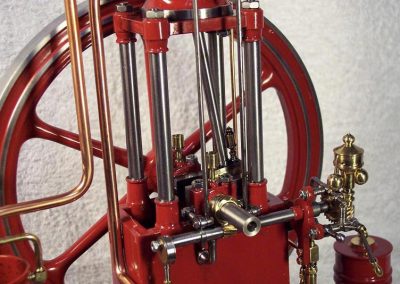

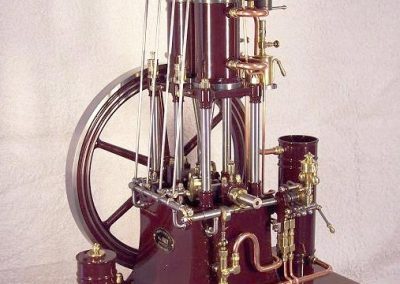

Four-Poster Hot-Bulb Engine

The water-cooled injector can be seen in this photo, above the flywheel rim.

Four-Poster Hot-Bulb Engine

The engine needs a continuous flame from the blow lamp to run. The bore and stroke are both 20 mm, and the fuel is kerosene.

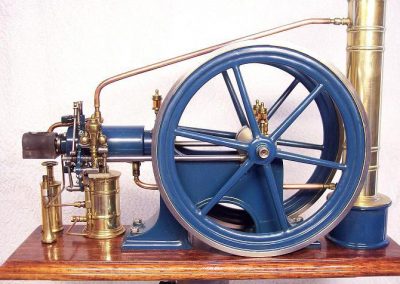

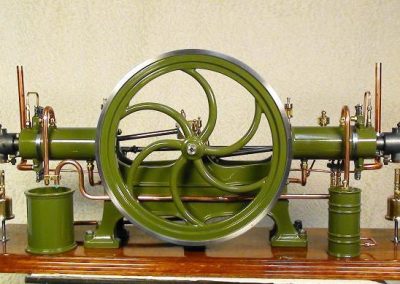

Horizontal Hot-Bulb Engine

This engine still uses a continuous blowlamp to heat the hot-bulb, and it has a water-cooled injector.

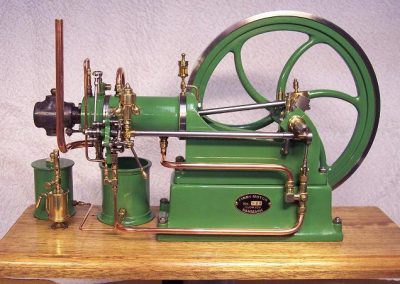

Lamp-Start Hot-Bulb Engine

On Find’s earlier engines, the hot-bulb would tend to lose heat to the water-cooled injector and the cylinder head, causing the engine to quit. Find moved the water-cooled injector from the hot-bulb to the cylinder head, and made a new bulb with a long, thin-walled neck (0.20 mm thickness).

Lamp-Start Hot-Bulb Engine

Continuing his improvements, Find made a long vaporizer tube, and connected it to the inside of the hot-bulb end. This created an indirect injection; not into the hot bulb, but onto the pre-heated vaporizer tube. That seemed to fix Find’s initial problem, and allowed the bulb to maintain heat.

Lamp-Start Hot-Bulb Engine

This engine differs from the one before in that it has a bore of 20 mm, and a slightly larger stroke of 32 mm.

Hot-Bulb Engine

This hot-bulb engine, built in 2004, has a slightly different layout than similar models. One feature common in all of Find’s engines can be seen here—a very nice paint job!

Inverted Hot-Bulb Engine

The following inverted, lamp-start, 4-stroke hot-bulb engines were freelance designs by Find. They were built between 2003-2004. They all use an injection pump and injector controlled by a fly-ball governor.

Inverted Hot-Bulb Engine

This engine design has a larger combustion chamber, because of the separately connected inlet/exhaust valve chamber on the outside of the cylinder bottom. This meant that Find had to increase the compression ratio to keep the hot-bulb warm.

Inverted Hot-Bulb Engine

Again, the bore on these engines is 20 mm, with a 32 mm stroke, and kerosene fuel.

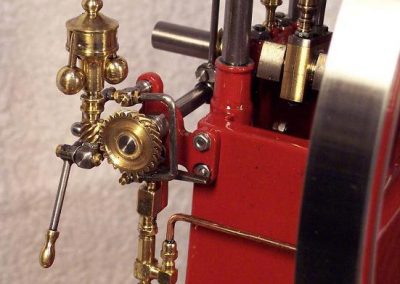

Inverted Hot-Bulb Engine

This close-up shows the water pump, and its worm gear connection to the side shaft. Three sets of worm gears were used on the engine: one connecting the crankshaft to the side shaft, one connecting the side shaft to the camshaft, and one connecting the camshaft to the fly-ball governor.

Inverted Hot-Bulb Engine

Another close view shows the fly-ball governor, and governor handle, at top right. The camshaft and worm gear are seen in the middle. The injector (lower center), and hot-bulb cover (near bottom) are also visible.

Blowlamp

A special blowlamp had to be made to accommodate the low heigh of the hot-bulb on the previous engines.

Blowlamps

This photo shows some additional configurations of blowlamps. Each sits atop a wine cork for size reference.

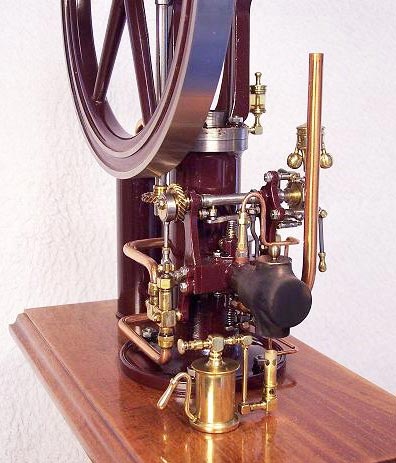

Four-Poster Hot-Bulb Engine

Like the horizontal engines, this model uses Find’s proven fly-ball governor controlled injection pump system for the hot-bulb.

Four-Poster Hot-Bulb Engine

Yet another variation of a four-poster hot-bulb engine, this one was built in 2007.

Four-Poster Hot-Bulb Engine

A close look at the cylinder head and rocker arms. The hot-bulb cover is the black part at left, and the blow lamp sits below it.

Six-Poster Hot-Bulb Engine

Find used the same governor system from the single-cylinder engines on this 2-cylinder, but it took some time to synchronize the injection pumps for a steady idle speed.

Six-Poster Hot-Bulb Engine

This photo shows a detail of the rocker arm injectors. The engine has a 20 mm bore, and 34 mm stroke.

Double Opposed Hot-Bulb Engine

This double opposed 2-cylinder hot-bulb engine was inspired by an engine built by Blackstone in 1904.

Double Opposed Hot-Bulb Engine

Find’s engine number 1-08 was built in 2008, and has a bore of 20 mm, and stroke of 34 mm.

Double Opposed Hot-Bulb Engine

This engine runs on turpentine, and uses the same governor system as the previous engines.

Double Opposed Hot-Bulb Engine

A closer look at the fly-ball governor that controls the injection pump.

Double Opposed Hot-Bulb Engine

This photo shows the crankshaft main bearing. It has oilers on both the main shaft—which drives the flywheel—and on the ends of the connecting rods.

Twin-Cylinder Horizontal Hot-Bulb Engine

This twin-cylinder horizontal hot-bulb engine is one of Find’s more recent creations. He submitted these photos in September, 2010.

Twin-Cylinder Horizontal Hot-Bulb Engine

A side view of the engine reveals the twin brass glow lamps in the lower left.

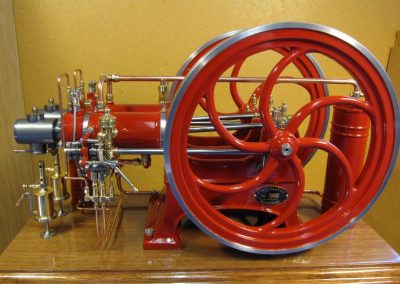

12 cc Diesel Engine Project

Scale Diesel Engine

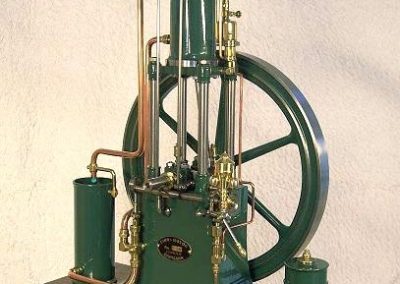

After first attempting to build a running Diesel engine in 1995, Find was finally successful with this engine. It was completed in 2011.

Scale Diesel Engine

In this photo, the handle being operated is the governor spring handle for controlling speed.

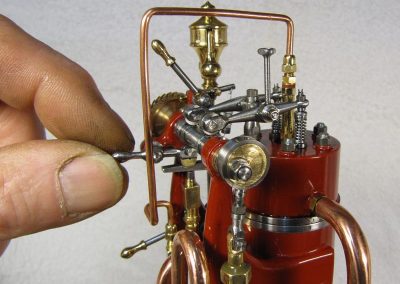

Scale Diesel Engine

In this photo, Find is operating the handle for the inlet rocker arm. This changes the stroke of the inlet valve, thereby changing the compression pressure. The engine needs a high pressure to start, but once it’s hot, the pressure can be lowered.

Scale Diesel Engine

This image shows the handle coupled to the governor system being operated. It controls speed, and is used for stopping the engine.

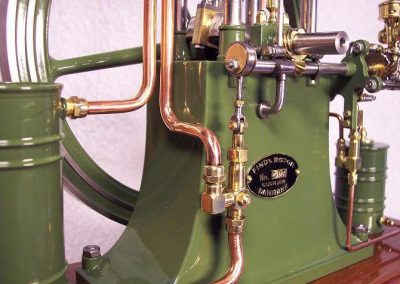

Scale Diesel Engine

Here we see the builder’s plate—the finishing touch on a fine, working model. The large flywheel looks great; however, it didn’t turn out to be as necessary for the Diesel as it was on the hot-bulb engines.

Cross-Drilling the Flywheel

When building a new engine, things don’t always work on the first try. This photo shows the flywheel being cross-drilled for a pin, as it came loose on Find’s third attempt to run the engine.