Below you can view more photos of Doug’s impressive scale model engines. Click on images to enlarge.

Scale Model Engines

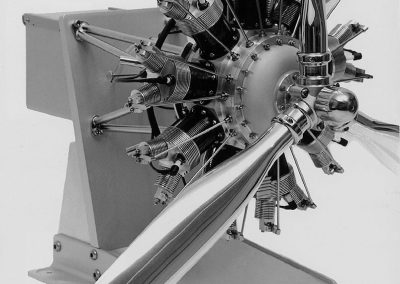

Hodgson 9-Cylinder Radial

Doug wrote a build essay for this radial, published in the September/October 2002 issue of The Home Shop Machinist. For a more realistic look, Doug built a 26.75” diameter, three-blade aluminum propeller for the engine. The blades were machined between centers on his lathe and mill, both manual machines.

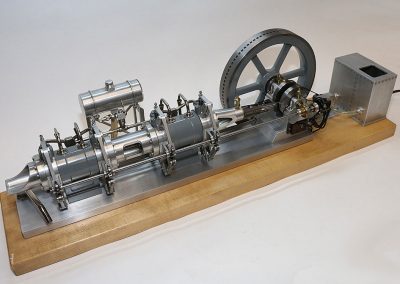

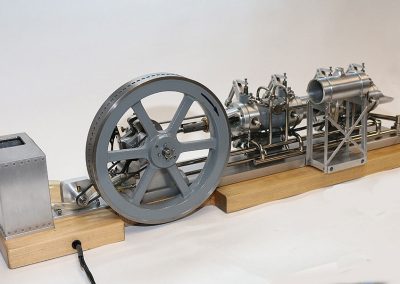

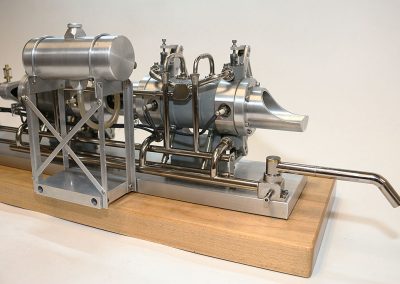

Snow Engine and Little Snow Engine

Doug followed his Snow engine with the Little Snow—scaled to 60% of the larger engine. The Little Snow has a 0.625″ bore, 1.125″ stroke, and a 5.375″ diameter flywheel. Unfortunately, drawings for the Little Snow were never published.

Snow Engine

The flywheel diameter is 8.5”, and a distributor takes care of ignition. The coolant pump is Doug’s own design, which includes a 1.25″ diameter impeller and a rubber lip seal on the shaft.

Snow Engine

The build was also published by Village Press in their, Build the Snow—A Tandem Double-Acting Engine, 48-page publication. Model Engine Builder magazine, Issue 14, published Doug’s centrifugal pump build article.

Snow Engine

In early 2016 Doug donated his prototype Snow engine to the Miniature Engineering Craftsmanship Museum, where it can be seen on permanent display.

Mill Engine

Speed control is based on the Callahan cam stopper concept. Coolant circulates to the radiator by thermosyphon.

Miller 2-Cylinder Engine

The center shaft, running at engine speed, drives 2:1 reduction gearing—which drives a short side shaft at each cylinder. The side shafts drive the exhaust cams and intake eccentrics.

Miller 2-Cylinder Engine

The Home Shop Machinist magazine published Doug’s photo essay detailing this Miller in the May/June 2009 issue.

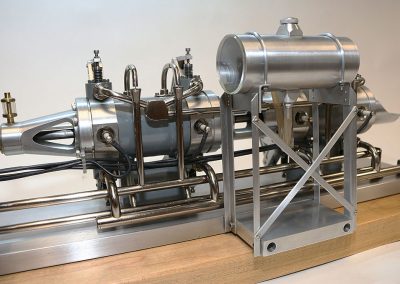

Opposed-Piston 2-Cylinder Engine

Fairbanks-Morse opposed-piston, Diesel engines were the inspiration for Doug’s opposed-piston, 2-cylinder engine. The bore and total stroke are 0.960” x 1.500”. The black component at the rear corner of the base is a computer water cooling radiator, and 12 volt fan. A gear pump circulates the coolant.

Opposed-Piston 2-Cylinder Engine

The twin flywheels are 2.250” diameter. Doug built a single-cylinder, opposed-piston engine to test this design before building the two-cylinder.

Opposed-Piston 2-Cylinder Engine

Doug’s article for the opposed-piston engine build was published in Model Engine Builder magazine, Issues 19 and 20.

Doug With His Hurricane Gas Turbine

Doug’s Hurricane gas turbine idles at 60,000 rpm, with 120,000 rpm maximum speed. Shown with the engine, Doug doesn’t run the turbine much over 100,000 rpm.

Hurricane Gas Turbine

Doug had the rotating assembly balanced at 100,000 rpm. The turbine spins on ceramic ball bearings.

Hurricane Gas Turbine

The combustor is made from 0.025” thick stainless steel. The end caps were formed over a simple die set. Doug made a series of steel and wooden fixtures to hold the combustor pieces in position while he installed the 1/16″ diameter rivets.

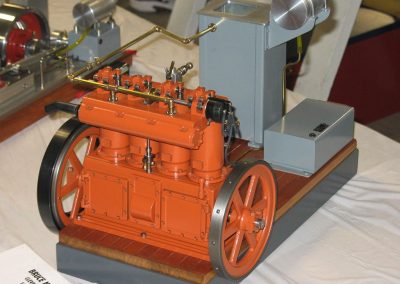

Bruce Macbeth Engine

Careful attention to detail gives this engine a realistic look, and the appearance of being built with castings.

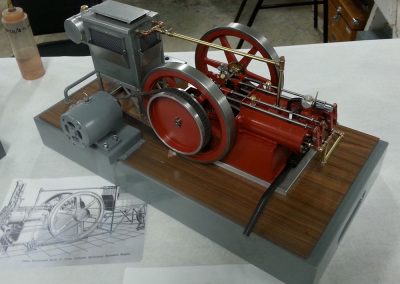

IHC Titan Engine

The Titan engine has a bore of 0.90”, stroke of 1.40”, and flywheel diameter of 5.97”.

IHC Titan Engine

Doug’s Titan is another fully fabricated engine, except for the cast iron flywheels.

IHC Titan Engine on HSM Cover

The Home Shop Machinist magazine planned to publish Doug’s Titan build article starting in 2016. The cover photo is shown here.

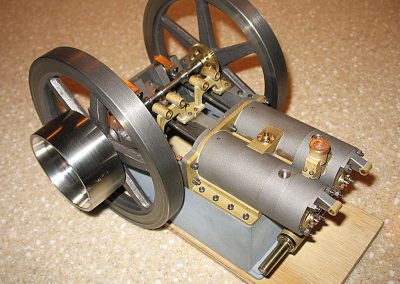

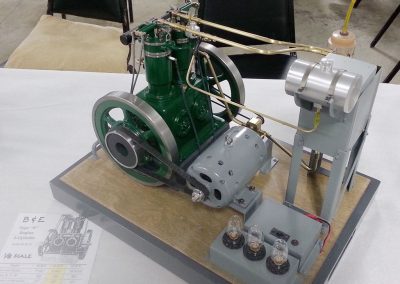

Bates & Edmonds Vertical Engine

This 2-cylinder vertical engine is a 1/8 scale model of the 25 hp Bates & Edmonds at the Coolspring Power Museum.

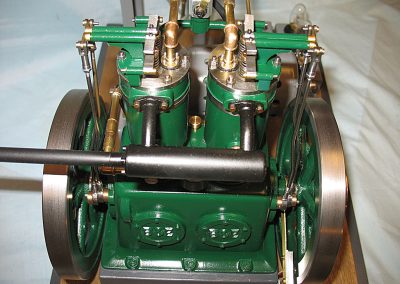

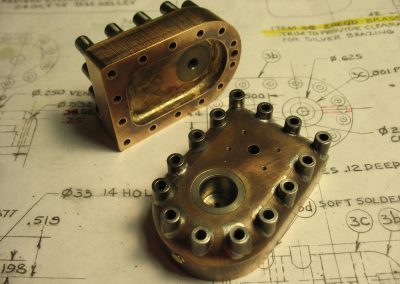

Bates & Edmonds Vertical Engine

Doug’s 2-cylinder Bates & Edmonds engine has no camshaft. Eccentrics operate the valves by pulling the rods connected to levers mounted on the cylinder heads (as shown in this photo with flywheels removed).

Bates & Edmonds Vertical Engine

The bore is 1.00”, and stroke is 1.187”. Flywheel diameter is 6.125”.

Bates & Edmonds Vertical Engine

The generator is a DC electric motor built into a housing that was styled to give a period look.