Micro Flint-Knapping—Miniaturizing a Prehistoric Hunting Craft

Scaling Traditional Techniques to Extemely Small Sizes

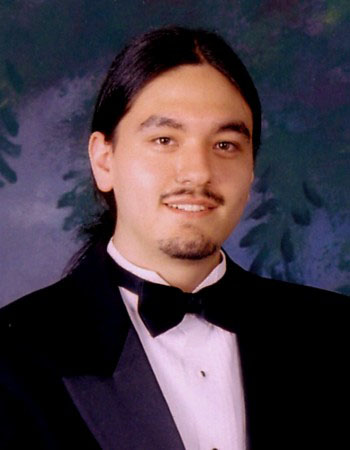

Dan White has been able to create his own unique work based on one of the earliest forms of art—flint-knapping (shaping stone by breaking off chips). Dan calls his method, “micro-knapping.” Prehistoric cultures learned early on that flint could be chipped to create sharp edges for knives, arrows, and spear tips. The ability to make quality points was critical, as it was the difference between eating and going hungry. Shape and size varied widely based on use and culture, but the technique has changed very little over thousands of years. Old points are popular among collectors, and some modern craftsmen have tried to duplicate the ancient techniques—but Dan has taken it to the extreme small end of the size scale.

Over the span of several years, Dan has made over 100 miniature stone arrowheads. He uses a stereo microscope to reproduce the Stone Age technology of flint-knapping in miniature. After months of experimenting, headaches, and stabbing at least a few fingers, Dan has been able to develop his own technique. As a result, he can now micro-knap miniature stone arrowheads the size of a grain of rice, which have all the same proportions and flaking as the full-size originals. Each miniature takes between 1-2 hours to complete.

These are some of Dan’s favorite micro points. A US penny at the top lends a sense of scale. From left to right, the first arrowhead is a T-drill style point made from Kaolin flint from Oklahoma. The second is another T-drill style made from Australian opal. The third is Dan’s smallest point, a paleo style fluted point made from Alibates chert from Texas. The fourth is an arrowhead made of striped opal from Australia. The fifth is a Dalton style point made again from Oklahoma Kaolin. The sixth is a “bolen bevel” style point made from quartz crystal from Maryland. The last tip is a stemmed point made from Brazilian agate.

Tools for a New Micro-Trade

Now, Dan’s tool kit consists of a thick rubber pad, a fine grinding stone, various small nails/pins for use as pressure flakers, and Scotch tape. (He must wrap his finger 4 or 5 times with tape to prevent the smaller nails from piercing him while flaking.)

Typically, Dan likes to use the most colorful stones he can find for his microscopic arrowheads. First, he starts with a flake of stone about the size and thickness of a nickel. He then begins breaking off large chips with a sharp copper nail to shape the stone down into a bi-facially flaked “pre-form.”

Once the pre-form is complete, it’s time to use the smaller nails and pins. Dan uses them to shape the piece down, and begin finishing the edgework and notching (or fluting). Notching is done with a small nail that has been flattened and sharpened.

Dan makes all the pressure flaking tools with the help of a microscope. Micro-knapping is basically the same as normal flint-knapping, in the way that each flake has to be removed in a very similar and precise manner.

Scarcity of Materials Leads to Miniature Craft

For most of his life, Dan has been a collector of ancient stone arrowheads. His interest in them is what lead to a pursuit of flint-knapping in the first place. When he first started trying to make arrowheads, Dan had no way to get large pieces of flint to practice with. So, he decided to make miniature arrowheads using tiny pieces of stone that had broken off of damaged arrowheads in his collection.

As far as he knows, he is the first person to ever try flint-knapping under a microscope. Since Dan had never heard of this before, there was no place to go for guidelines or advice. It took several months to develop his technique, and to figure out the right tools to make.

After much practice and pain, Dan was able to make a miniature arrowhead under 2 mm long, with sharp edges, and flaked on both sides like an original. His smallest arrowhead was considered for the Guinness Book of World Records, but because there is no category for arrowheads or flint-knapping he was turned down.

However, some of Dan’s work is in the Smithsonian Collection, and his smallest piece has been photographed by them as well. He has sold some individual miniatures to collectors in the past, but would rather keep most of them to enjoy for himself—especially since they are so difficult to make!

Early Difficulties Solved With Better Tools and Techniques

When Dan first started, his only tools were the microscope, a pin for the notching, a pocket knife, and some card paper. He would find the thinnest, flattest chip of stone, and then shape the edges down with the tip of the knife blade. Dan did this while holding the stone between his fingers in a piece of card paper.

The first 10 or 15 were crude looking, and not bi-facially flaked (flaked equally on both sides). He used the pocket knife for a while, before realizing he could never get the results he wanted with such a hard chipping tool. That’s when Dan started using nails, and placing the stone on a rubber pad to get longer pressure flakes.

When first starting out, and trying to teach himself how to make the tiny points, Dan would break 2-3 for every one that he finished. After finally getting the tools and technique just right, he says he can now make 2-3 (if he’s very careful) before he breaks one.

According to Dan, “The hardest part is doing the notching and the flute flakes for the Clovis style points. Naturally, most of the breaks happen after much of the work is already finished. If I can get the arrowheads to look good under the microscope, they will look really good to the naked eye, but sometimes I break them on purpose if they don’t look just right.”

These micro points are all made from Alibates flint, found by Dan’s late friend, George Chapman. They were found near Alibates Flint Quarries National Monument, the famous ancient quarry in the Texas panhandle. George lived near the quarry, and he would send Dan a pile of small flakes in exchange for a finished point or two. This is some of Dan’s favorite material to work.

Dan admitted that he has dropped a few of the arrowheads, only to be lost in his carpet—including a few of his best points. After spending over an hour looking each time, Dan had to give up in frustration. Even so, he says that working this small is worth it.

Interestingly, Dan met the 2006 Craftsman of the Year winner, David Kucer, at an antique show in the past. David is undoubtedly experienced in miniature work, and was very impressed with Dan’s miniature arrowheads.

This is Dan’s smallest arrowhead, a fluted and bi-facially flaked Clovis-style point that measures just over 1 mm. According to archeologist Dr. Dennis Stanford at the Smithsonian, and the people at Guinness Book of World Records, this is the smallest knapped stone arrowhead they have ever seen. This is the only one that Dan has made this small, and he noted that he likely wouldn’t try it again. When making it, Dan had to hold the point on his pad using a popsicle stick, while flaking it with a special tool he made just for this project. It took about 1-1/2 hours to finish.

View more photos of Dan White’s microscopic arrowheads.