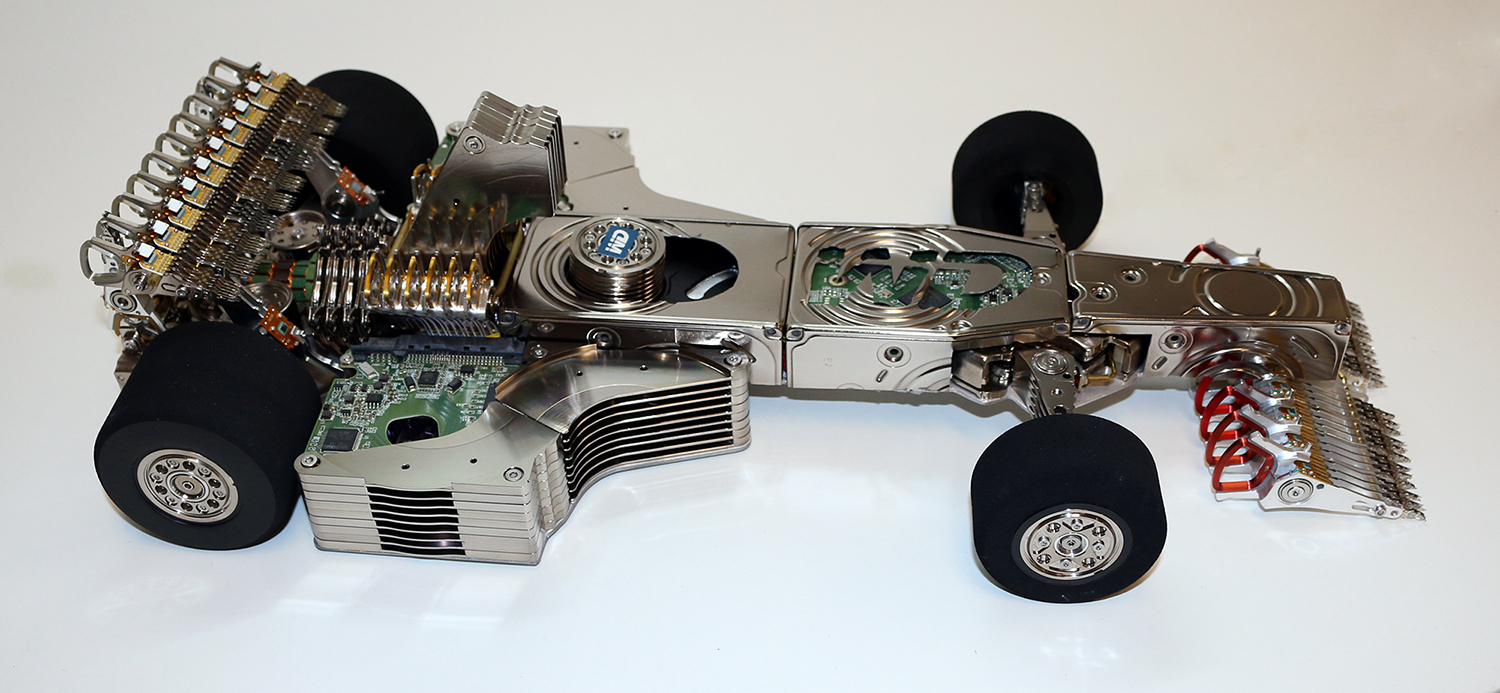

Rob Ryan and his son started this project by first working with a plastic F1 kit they had purchased. Using the plastic model as a pattern, they began to construct their Western Digital (WD) F1 car. Internal Components from several different types of WD hard drives were used for construction. A total of 250 hard drives were collected, disassembled, and crafted to create this very unusual car. The wheels and the tires are the only parts not made from WD hard drive parts.

The wheel hubs are made from 10,000 rpm and 7,200 rpm hard drive motors. WD Red® hard drives were used to build the side panels of the car and engine air scoop using stacks of the anti-disks. The actuators of the WD Red® hard drives (the arms that read data on the hard drive) were used to form the front wing of the car. The rear wing and mount are made from WD VelociRaptor® and WD Scorpio® actuators. The front and center of the body is cut from WD Scorpio® top covers.

A small stack of disk spacers on a 7,200 rpm motor in the middle of the car represent the driver’s head. Behind the driver is the replica V12 engine using the actuators from 12 WD Scorpio® notebook hard drives. The transmission is made up of stacks of WD Scorpio® VCM magnets. The differential is a stack of spindle motor windings from many different types of motors. The LED and driver circuits in the body are cut from sections of Western Digital WD My Passport® external hard drive boards.

The WD F1 Car is powered by a 12-volt power supply. Custom “C” controller code that was written by Rob spins the drivers head and flashes the LED lights at varying times when power is applied. Build time: 400 hours. Material: WD hard drive parts. Hard drives used: 250. The Formula 1 car was built by Rob Ryan and family and is on loan to the museum courtesy of Mr. Ryan. Watch a video of the WD F1 car below.