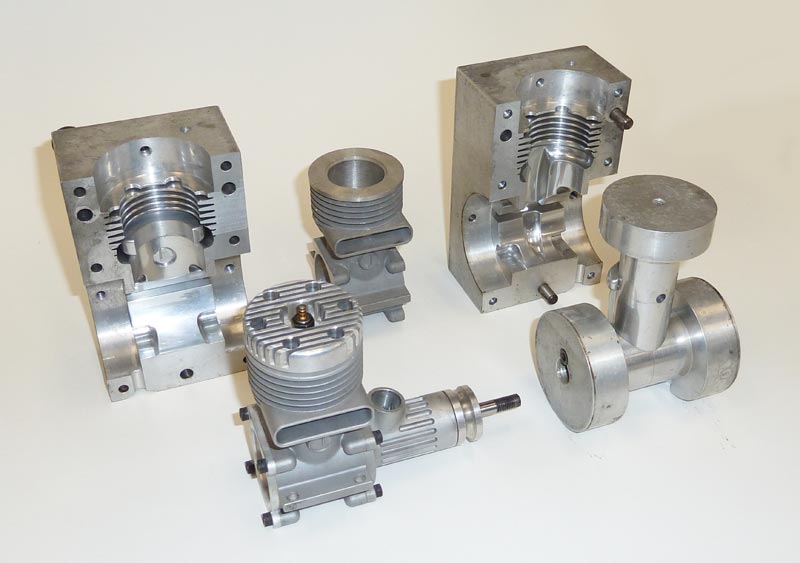

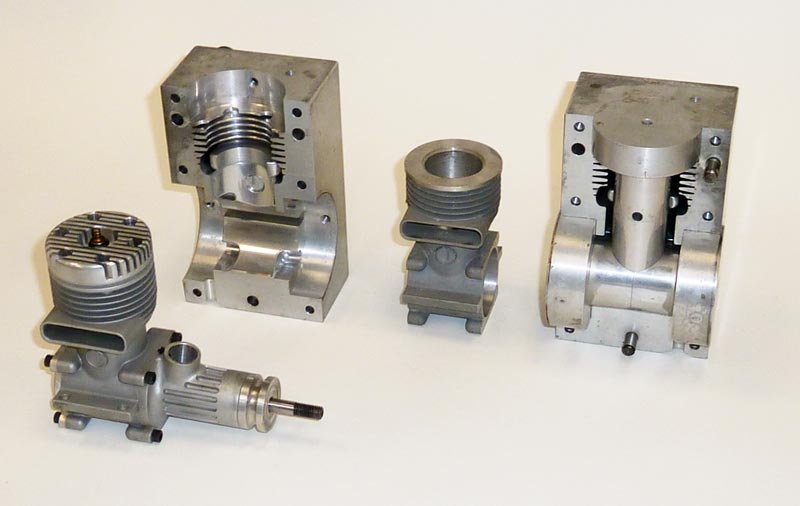

The molds shown here were made for the Cooney .61 side port engine. The first photo shows the mold halves with the cores in place in the right half. The second photo shows the molds with the cores removed. The cores must be made in pieces so they can be extracted at various angles from the wax master once it cools. They are what leave the hollow cavities inside the engine. Fits must be near perfect, meaning a whole lot of expert machining work is done before the first part can ever be cast. The last photo shows several wax masters. Ralph Cooney also produced molds for an engine that was sold by Kraft Systems.