Below you can view more photos of John’s clocks. Click on images to enlarge.

Clocks by John Wilding

M.E. Jubilee Clock

This clock was originally designed by E. T. Westbury, and covered as a serial in Model Engineer in 1958. John sorted out a couple of problems with the original design in his improved version. The clock is similar in appearance to the “master” type of clock, with a one seconds pendulum. It uses the Scotts notched tooth principle of pendulum propulsion. The drive to the hands is also taken from the notched tooth count wheel. Using a 4.5 volt dc power supply, the clock is accurate to within a few seconds a week.

Crystal Wheel Skeleton Clock

Horologists will recognize this clock as a close copy of the famous flint glass wheel clocks, made by Edwards of Stourbridge. The clock is mounted on a wooden box containing the barrel. The designer obviously thought that the barrel was not aesthetically pleasing, and hid it in the box so as not to spoil the appearance of the flint glass centered wheels. The clock and box together stand 22” high, and are quite impressive. The crystal wheel centers are engraved with a sunburst pattern, which together with the elegant scroll frames, make it a very attractive clock.

Castle Clock

This is an 8-day, weight driven wall clock designed for a shelf bracket. The movement is exposed to view. The movement is fitted with maintaining work, and “one at the hour” striking. Once again, John designed this clock to be built on a modern, small benchtop lathe.

Tavern or “Act of Parliament” Clock

This type of large wall clock is often seen in churches, village halls, schools, etc. It should maintain accuracy within five seconds a week, and runs eight days on one winding.

8-Day Wall Clock

This is an updated version of John’s original 8-day, weight driven wall clock. This one includes some improvements to the wooden case, and the addition of a seconds hand.

English Dial Clock With Datework

These clocks were produced in large numbers right up to the 20th century. Their quality fusee movements, together with the easily read dial, made them both practical and efficient. This one is fitted with maintaining work and optional datework.

Brass Alarm Clock

John designed this weight driven, brass alarm clock as a beginner’s project. It’s a wall clock with a 30 hour duration. The escapement is the semi circulus, or strob, as used by Richard of Wallingford in the St. Albans clock. This escapement employs a double escape wheel, each with radial pins in its periphery, and is used in conjunction with a foliot as the oscillator. The movement was designed for a single hand, but a minute hand was added to the design due to popular demand.

Large Balance Wheel Electric Clock

This clock was based on the Murday-Reason battery clock, manufactured in Brighton at the beginning of the 20th century. John made several modifications, including a balance staff in ball races, and a simplified mechanical arrangement for the drive of the hands. The oscillation of the large balance wheel is spectacular in its action. The clock employs the Hipp toggle principle to maintain the swings of the balance, and runs on a 3-volt battery.

3/4 Second Pendulum Electric Clock

John designed this clock to be suitable for a complete beginner—with regard to both clock making, and operating a lathe. The clock was serialized in Model Engineer.

Drum Water Clock

On this clock, the drum itself is made from perspex sections, in order to show the action of the water inside. John detailed three different methods for utilizing the rotation of the drum to indicate the time. The clock requires winding daily, and this is done by gripping the winding knobs at each end of the center spindle and turning them. That causes the drum to climb up the two cords from which it is suspended.

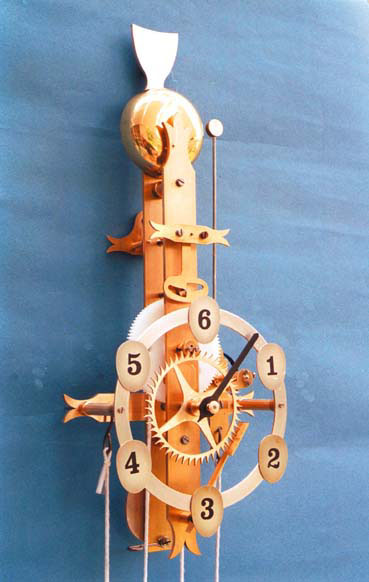

Large Wheel Skeleton Clock

This clock features simplicity of design in the inverted “Y” frames, together with the large main wheel. Another interesting note is the equal size of both the third and escape wheels. This balances the upper part of the clock. It’s driven by a mainspring in a “gong” barrel, and has optional stopwork.

18th Century 30-Hour Alarm Clock

The posted movement for this weight driven alarm clock has two trains, one behind the other. John used nothing more than his Myford ML 7 lathe, and a drill press to make this clock. The movement is fitted with a hanging ring and spurs, and can be mounted on a wall or cased as shown.

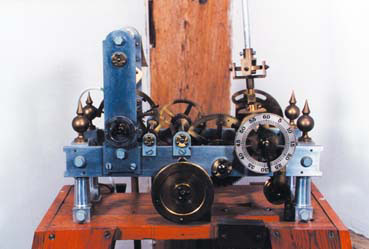

Weight Driven Tower Clock Movement

Many find it challenging to build a clock that can drive hands that are exposed to the weather. This relatively large movement is capable of driving a single exposed dial up to 2 feet in diameter. Even so, John built it all on his small Myford 7 lathe.