A Variety of Skills Applied to Model Engineering

Introduction

At the 2003 Pacific Rim International Model Exposition in Eugene, Oregon, Joe Martin spotted some models that not only had the craftsman’s touch, but also exhibited a great variety of learned skills and techniques. This included casting, machining, woodworking, and sound model engineering. The work was from a craftsman named Clif Roemmich, and we felt that visitors would enjoy seeing some of his projects for themselves.

Fix It or Do Without—Learning to Build From an Early Age

Clif Roemmich is a native of South Dakota, born in Aberdeen in 1947. While growing up on a farm, Clif learned early mechanical skills from his father. During the farming years, and living at home with his parents, money was short. If things could not be repaired, it was “do without.”

Clif recalled an interesting memory of one of his first mechanical experiences. His father had removed the flathead V-8 engine from a 1948 Ford, set it on the ground, and said, “I am going to the fields. Take it apart so I can inspect it for rebuild when I get back.” This was at the age of just 7 or 8 years old, and Clif remarked that the head bolts were tough!

By the time Clif was a teenager, the family had moved to the Black Hills of western South Dakota. He spent a summer mowing lawns in order to purchase a series of project kits from a supplier called American Basic Science Course, after seeing their ads in Popular Science magazine.

The projects included building a radio, analog computer, electric motor, and developing photos. The education and skills that came from these kits helped lay a foundation for future projects.

This Gothic steam engine is a 1/12 scale model of an engine that was located in the Henry Ford Museum. Clif especially enjoys building models of engines that have an extensive history. The original engine was cast in 1851, and in service for 74 years. The flywheel on the model is 18″ in diameter. This was well beyond the capability of Clif’s shop lathe. He machined the flywheel on an 1895 Barnes lathe that was installed in a farm workshop in the 1930’s.

The old Barnes lathe that Clif used was belt driven by an electric motor that looked old enough to have been built by Thomas Edison himself! Clif had a little trouble learning how to run the old lathe, but in the end it did a great job. Surely, the builders of this old lathe could not have guessed that after 107 years, the machine would still be working.

When Clif reached a driving age, the first car he bought was built the year he was born. Needless to say, his mechanical skills needed to grow just to keep it running. Because of his early mechanical prowess, Clif was often called upon by other teenagers for car repair.

As he grew older, these mechanical skills would come in handy. After graduating from high school, Clif joined the South Dakota National Guard. He was trained as a combat engineer, and also as a water purification specialist.

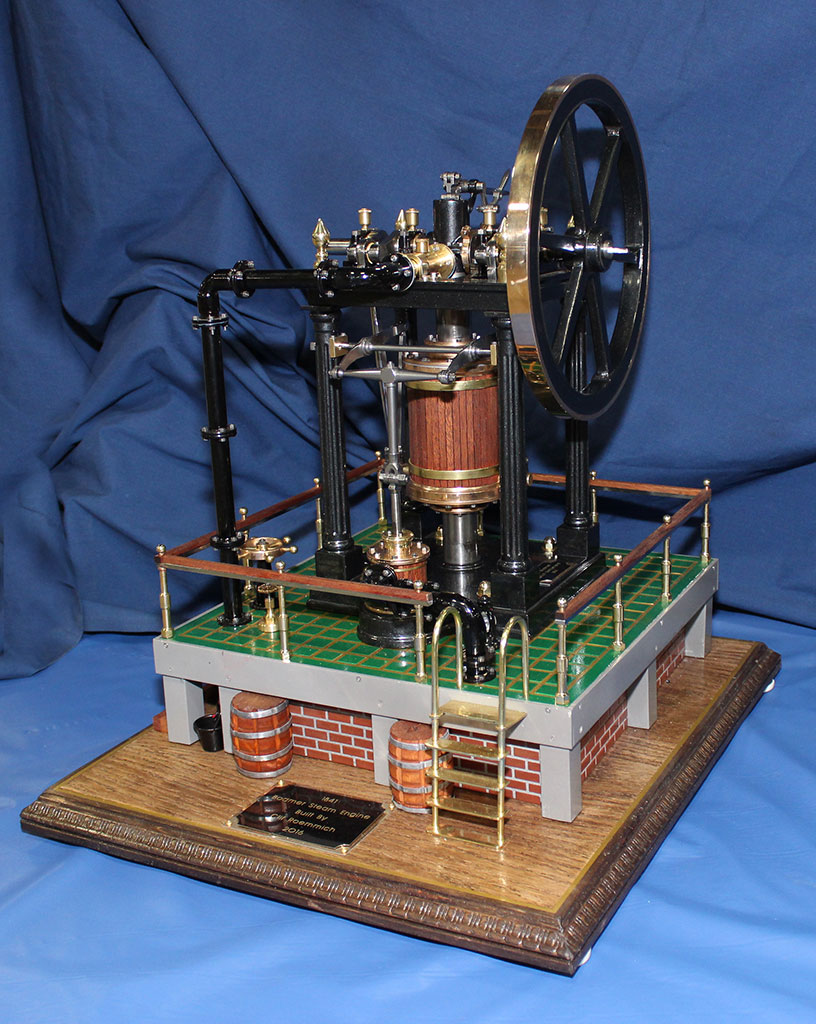

Whether this 1841 Johann Bodmer sliding cylinder steam engine was ever built at full-size is unknown. The existing drawings from 1841 are for a marine paddlewheel engine. Clif built his own scale version, which was displayed at the 2016 NAMES Expo.

From Gas Station Tune-Ups to Shop Foreman

After returning from military basic training, Clif worked in a gas station for almost a year, doing tune-ups and light mechanical work. Shortly before his 20th birthday, he went to work for an electric utility company as an apprentice electrician. Two years later, Clif transferred to a job in a welding and mechanical maintenance shop.

Clif worked there for 18 years, eventually becoming the shop foreman. The shop work included vehicle maintenance, hydraulic equipment maintenance, metal project fabrication, and welding.

The job also included the repair of a wide range of electrical and mechanical equipment. After 36 years of service, Clif became a part of middle management for the utility.

Clif married at 20, and he and his wife Judy raised two children. While the children were growing up, Clif and Judy owned and operated a commercial greenhouse for 17 years. Clif constructed and maintained all of the buildings for the greenhouse in his spare time. In what little free time was left, Clif served as a Cub and Boy Scout leader for 9 years.

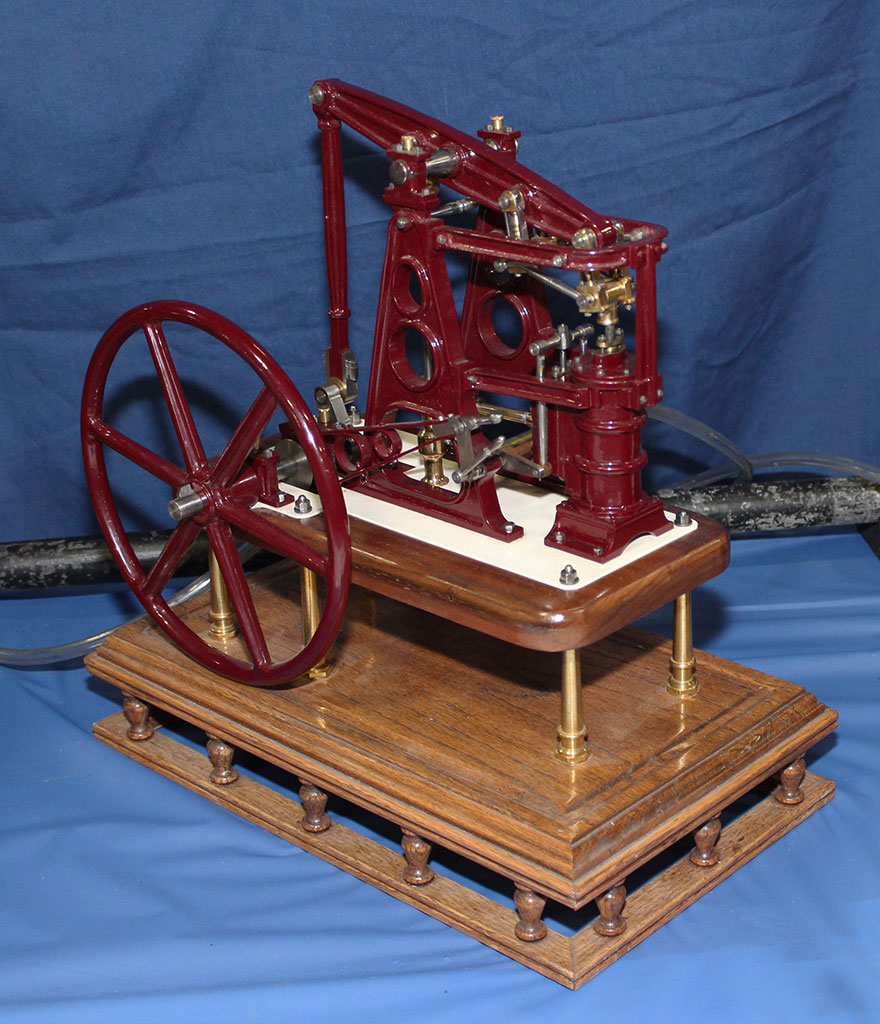

The 1840 Murdock-Aithens steam engine was an English design. Clif’s 1/12 scale model was based on a drawing from 1874. He completed the engine in 2005.

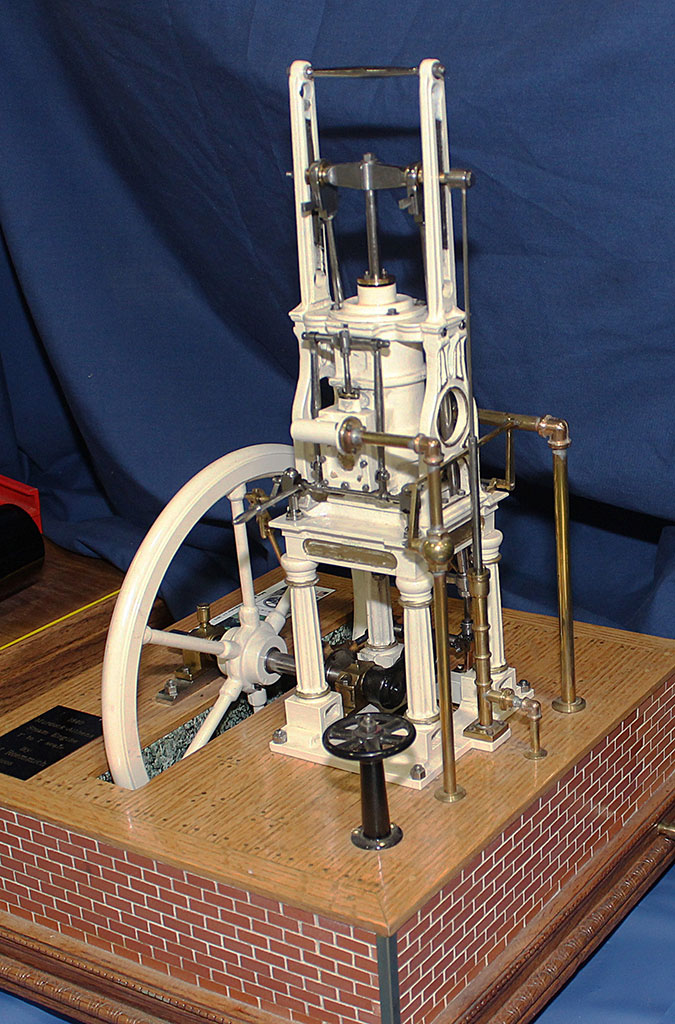

This 1830 Vulcan steam engine is a real old-timer amongst beam engines. It evokes an era of early historic steam engines, when they were becoming self-contained with all-metal construction. This engine is representative of the early transition away from the use of wooden beams, with the engine structure being part of the engine house. Clif built this model at 1/12 scale.

From Wood Turning to Metalworking

In high school, Clif had taken wood shop all four years. He developed into a prolific furniture and cabinet maker. The wood shop also had an old South Bend lathe. Clif took an interest in learning to run the lathe, but instruction was limited. In order to feed his hunger for machining knowledge, Clif began hanging around the local machine shop, watching the machinist ply his trade.

Clif also got his hands on the shop course textbook, which had a section devoted to greensand metal casting. Again, no training was available. When Clif graduated, he bought a copy of the textbook with the hope of someday learning to cast metal. Shortly after he began working in the utility company shop, Clif bought an old South Bend lathe.

Unfortunately, the old lathe had been in a garage fire, so it was covered with tar from the melted roofing (and had sat outside for a number of years). Even so, it was a great find at $100. Once it was cleaned up, repaired, and painted, the 1935 lathe marked the beginning of 35 years of machine tool self-education.

Accessories were purchased bit by bit, and through trial and error, Clif began to develop the skills of a machinist. The progression went from lathe to milling machine attachment for the lathe, to table top milling machine, to floor model milling machine, to a modern lathe and a surface grinder.

Clif’s well-equipped home workshop.

Over time, Clif’s skills were developed through a number of hobbies, including building black powder guns, rubber band airplanes, plaster craft, carpentry and blacksmith projects. At about 30 years old, Clif began collecting and rebuilding antique gas engines, tractors, and machinery. He was also a very active member of the local steam threshing bee.

During this period, Clif built an automobile using a horse-drawn buggy and a 1921 single-cylinder engine. He also restored an antique cable-drop well drilling machine, and attempted to drill a well on a piece of property he had purchased. Ultimately, the well project was abandoned after drilling 28 feet, but that’s another story. After filling three buildings with his restored items, Clif realized that as he grew older he would not be able to move and display them. Naturally, an auction soon followed.

Around 1995, Clif became a member of the board of directors for a newly formed local blacksmith club. While working with the club members and building a gas fired blacksmith forge, Clif recalled his high school desire to cast metal. A search for his old high school shop textbook was successful, and thus began Clif’s metal casting development.

The blacksmith forge gave way to a newly constructed gas fired metal foundry. With the purchase of a good library on sand casting and pattern making, a number of new projects were completed. The high point of the period was the development of a 1/2 scale model of a four horsepower, side valve Witte hopper cooled engine. The Witte was patterned, cast and machined by Clif.

Midwest Model Builders Club

In the mid 1990’s, Clif decided to try to form a club of hobbyists with similar interests. As a result, the Midwest Model Builders Club was organized, and members started to meet on a quarterly basis. The focus of the club is to provide a network where craftsmen can interact and share their knowledge with others.

After attending a model show in Detroit, Clif decided to see if he could get a model engineering show started in western South Dakota. The effort was successful, and the Black Hills Model Engineering Show has been held annually since 2001.

With years of experience, Clif has developed the skills to work with both wood and metal. The majority of his projects have been based on castings and plans purchased from others. Some of Clif’s projects have been built from an idea, planned in his head, and usually executed without drawings.

One example is his model Avery steam tractor. Clif got to work around a full-size Avery while he was a member of the steam threshing club. After eleven years of examining pictures and planning the project in his head, Clif began building the tractor.

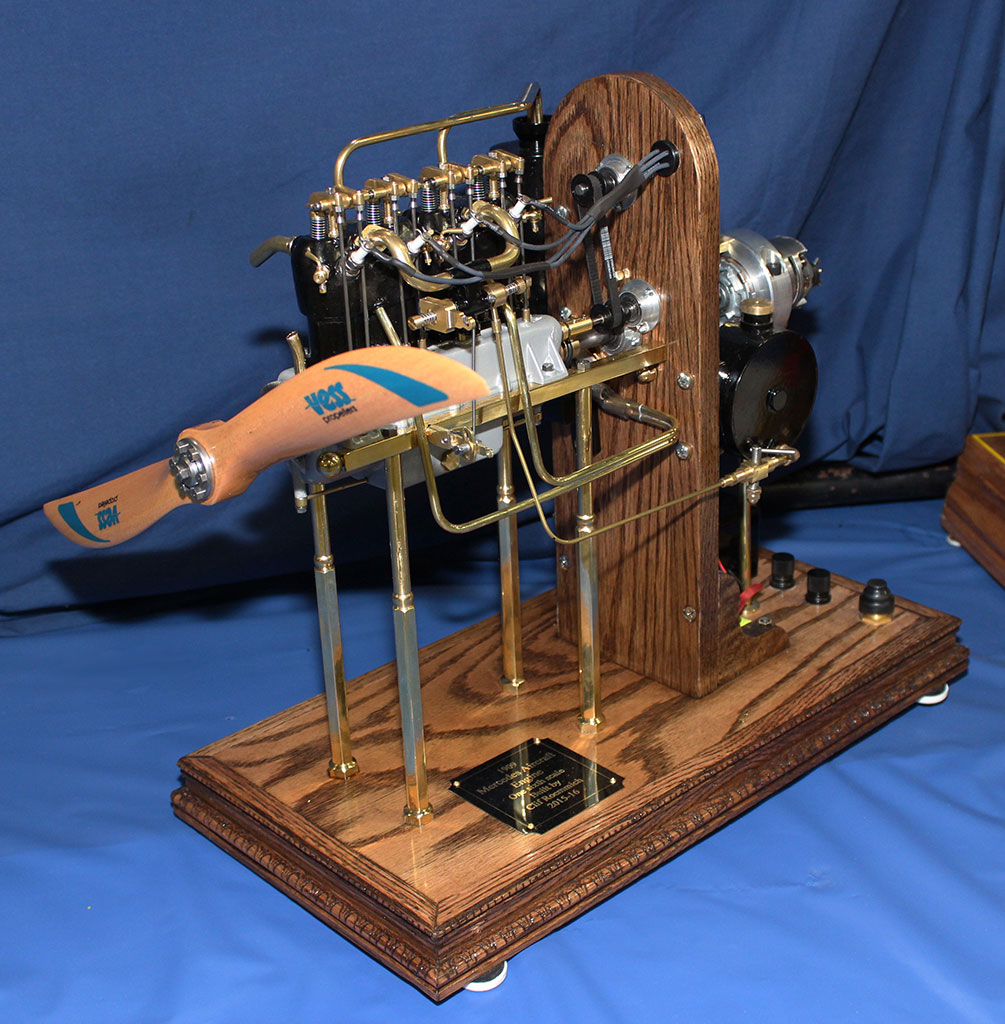

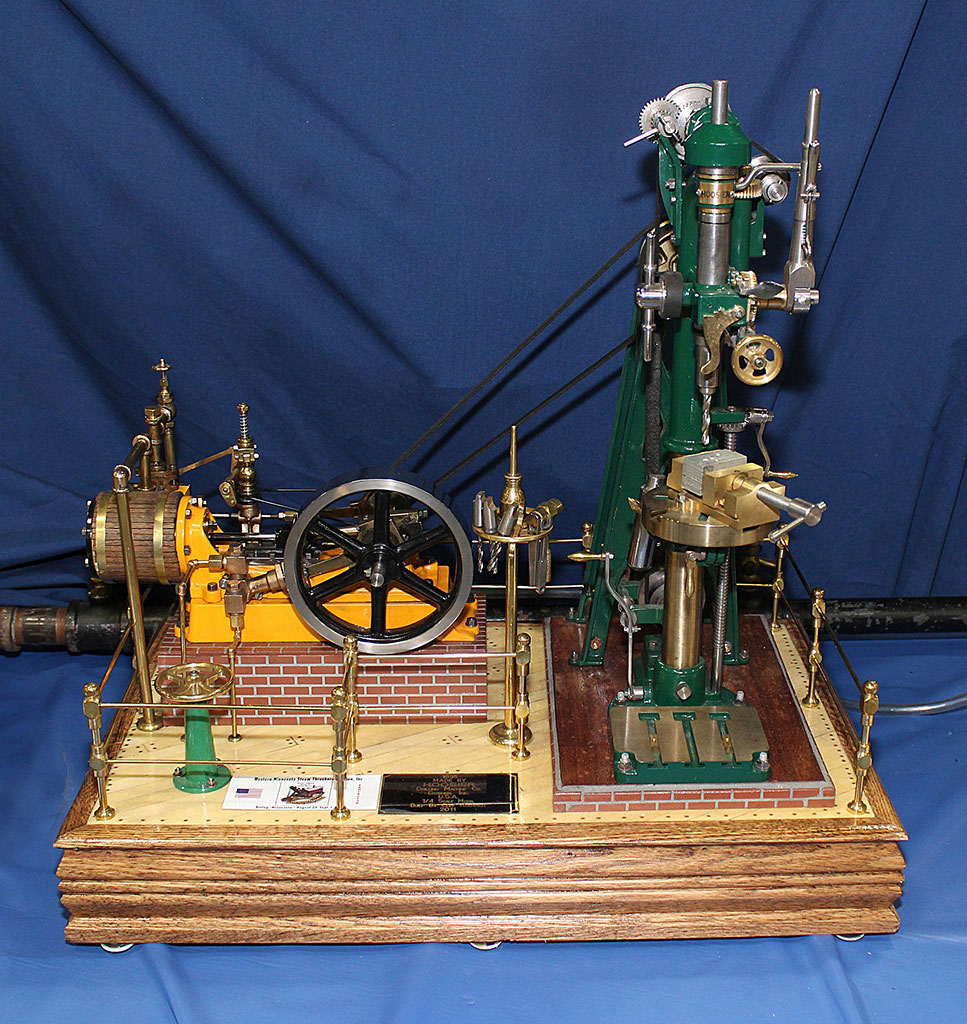

Clif’s 1/4 scale 1899 Camelback drill press. The name refers to the peculiar humped cast iron center frame on which the main shaft, pulleys, and gearing were built up. The Camelback has the most distinctive appearance of any drill press ever manufactured. This is an antique style that was made at the end of the 19th century, but lasted well into the 20th century. In fact, they were still being made up until the 1970’s. Today, these antique style drills are often found for sale when older welding and blacksmith shops go up for auction. Some people are skeptical of these old drills—often mistakenly believing that they don’t work simply because they don’t look modern. But to those who use them, these old style drills are very practical, and highly desirable for nearly every drilling job.

Clif’s Avery steam tractor project was completed in five months. He noted that as he builds, he has a constant goal of improving his skills. While working full-time, Clif still devoted 20-30 hours per week to model building. Having finally retired, he has more than enough projects waiting in boxes—or in his head—to keep busy for a few lifetimes.

View more photos of Clif Roemmich’s model engineering.