A Model Engineer Who Specializes in Building Unusual Engines

Introduction

Retired engineer Doug Kelley honed his design skills developing large, off-road haulers for Euclid. Today, Doug’s design work is on a much smaller scale. He enjoys modeling nearly forgotten, historic, multi-cylinder engines with names like Bruce Macbeth, or Bates and Edmonds. Doug is probably best known for his model of the tandem, double-acting Snow engine.

About Doug Kelley

Doug Kelley was born in Harrisburg, PA, and grew up on 3rd Street, a few blocks from the Susquehanna River. From an early age, Doug was interested in all things mechanical, though bulldozers in particular were his favorite. He recalls cruising around Harrisburg on his bicycle, looking for bulldozers at work. He would also ride his bike to the nearby International Harvester dealership, where Doug says he made a pest of himself climbing on the machines and hanging around the shop.

Recognizing Doug’s interest in the machines, the mechanics sometimes let him ride along while testing crawler tractors and scrapers. Doug learned to run a crawler, dragging logs out of the woods on his grandfather’s Oliver HG. His interest in construction machinery, and experience on the HG, led Doug to summer work at a local construction company during high school and college. He started out digging ditches with a shovel, but kept pestering his foreman to put him on a machine.

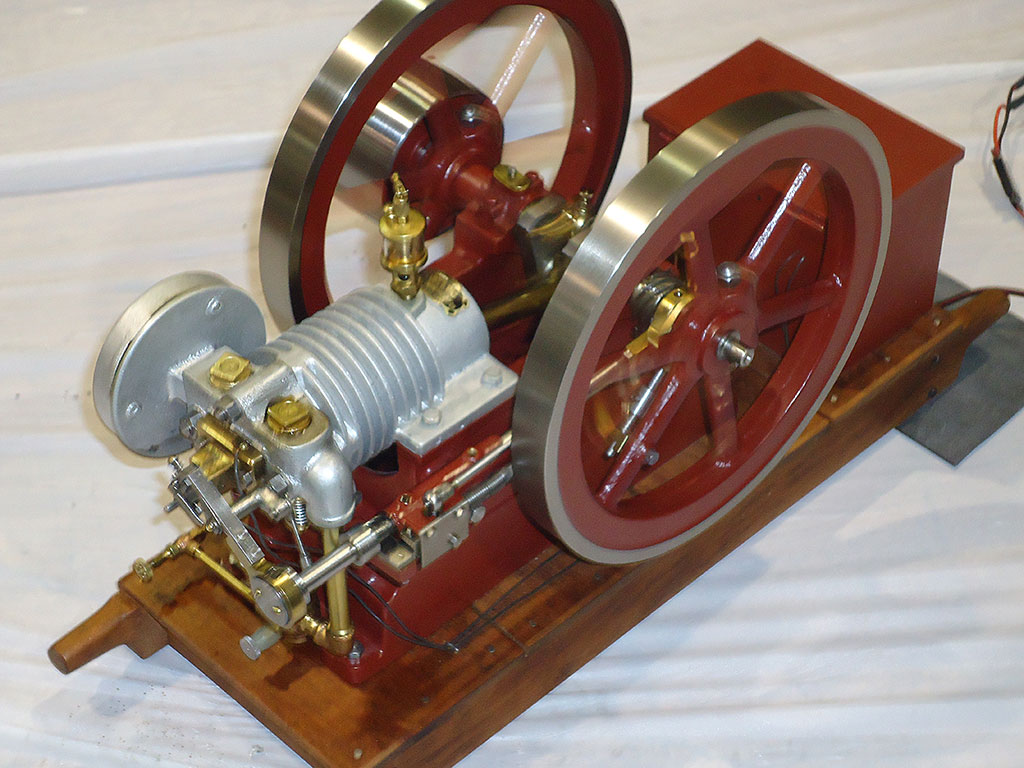

Doug’s first model was this 1-1/2 hp Domestic, built from Bob Herder’s castings. This ignitor-fired, hit-and-miss Domestic, with working governor, has a 1.00” bore, 1.50” stroke, and 6.12” diameter flywheels.

Eventually, Doug got to run an Allis Chalmers HD-6 dozer, but spent most of his time on a 12-ton Huber road roller. Doug had many adventures on the roller, including the morning he was told to drive the machine back to the contractor’s yard. The route went right past Doug’s house, and it was lunchtime when he was going through that area. To his mother’s great surprise, Doug parked the roller on the street out front and went in for lunch.

Living close to the Susquehanna, and not far from the Williams Grove Speedway, Doug developed an interest in hydroplane and sprint car racing. He was particularly fascinated by hydros running the 48 cubic inch Crosley, and the really hot Ford V-8 60 engines.

At Williams Grove, Doug’s favorite driver was Troy Ruttman driving the 220 Offenhauser powered Agajanian #98 Jr Special. Doug never had the money to build a hydroplane, but he and his friends spent a lot of time on the river. He rebuilt a number of old 2-cylinder outboard Johnson, Elto, and Champion motors, which he bought from garages on Front Street.

They built wooden boats from whatever they could find, and powered them with Doug’s rebuilt outboard motors. In addition to the boat motors, Doug bought a Ford 60 engine from a local junkyard and rebuilt it in his parents’ basement.

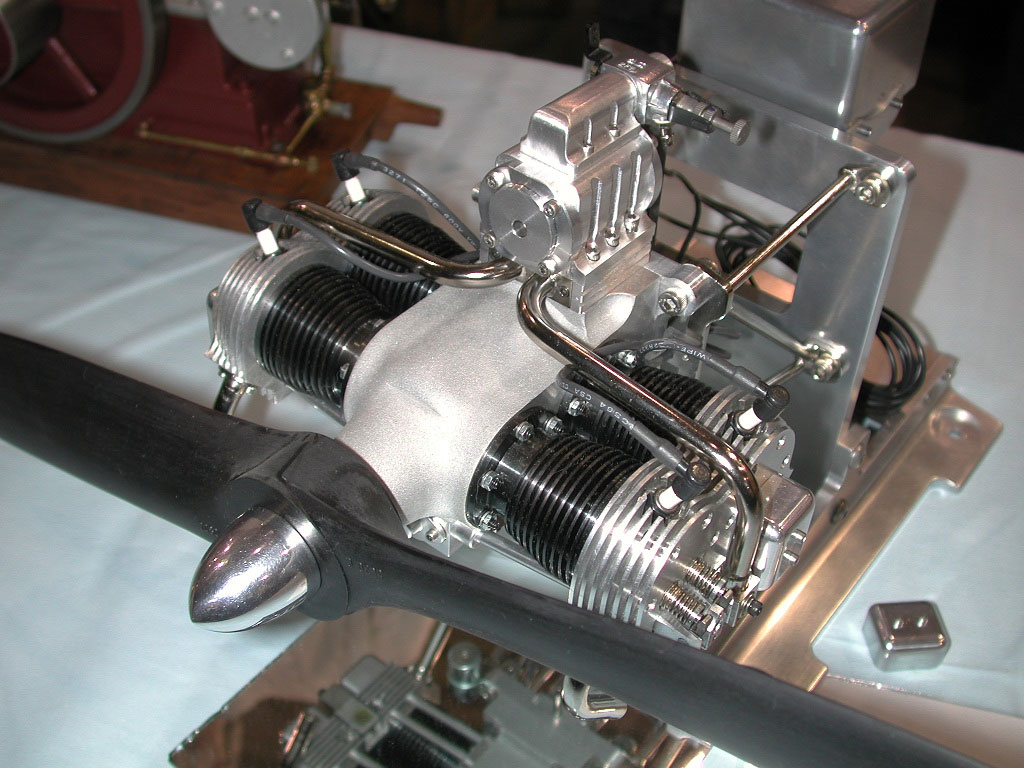

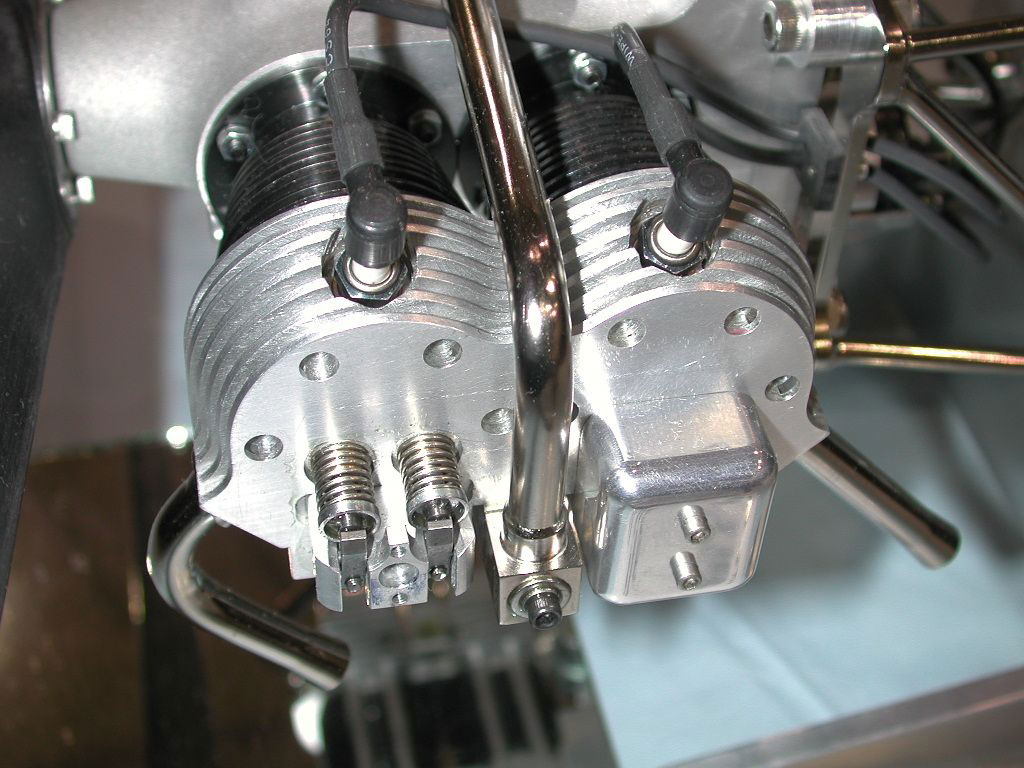

This Bruce Satra 0-440 flat 4-cylinder aircraft engine has a 0.940″ bore and 0.875″ stroke. The engine is spark plug fired, and has a rear mounted Satra designed distributor.

Pursuing Engineering In College and the Workforce

As might be expected, Doug’s boyhood interest in engines and machinery led him to study engineering at Penn State University. He graduated in 1956 with a degree in Industrial Engineering. After interviewing with several construction equipment companies, including Caterpillar, Doug took a job with the Euclid Division of General Motors in Cleveland, OH.

Three weeks after graduation, Doug and his new bride, Jane, headed west to Cleveland in his 1954 Chevrolet. He worked for Euclid for 28 years in off-highway hauler project design, product development, and marketing. Doug loved the work, and the chance to travel the world.

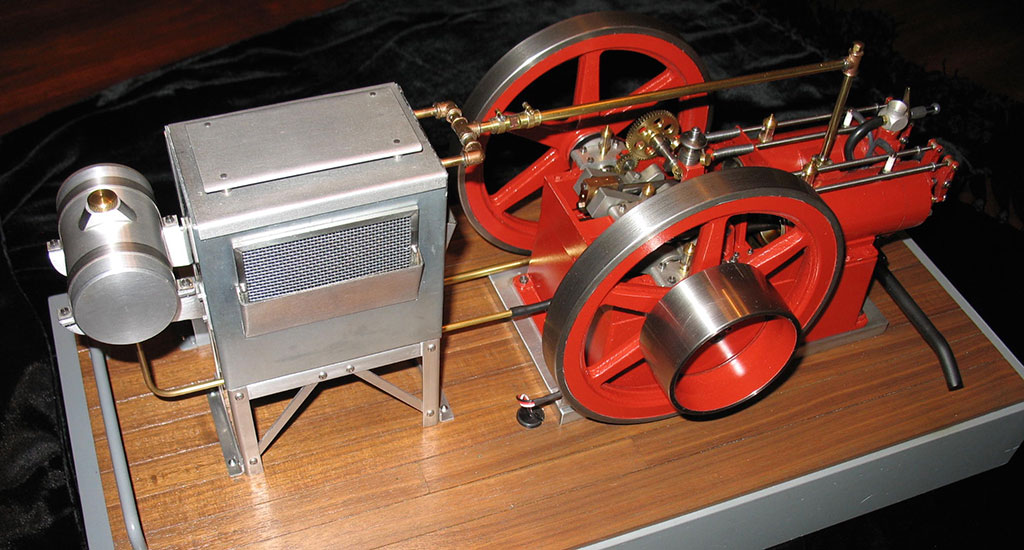

Doug’s mill engine is a freelance side shaft engine of his own design. The bore and stroke are 1.125” by 1.750”. The flywheels are 6.50” in diameter.

A Small Gift Leads to an Interest in Metalworking

In the early 1970’s, Doug’s father gave him a 1-1/2 hp Hercules engine that he had bought at a local farm sale. The Hercules was a perfect introduction to the early thinking in internal combustion engine practice. The Hercules soon led to a modest collection of antique engines. Restoring antique engines led to the need for metalworking tools, prompting Doug to buy his first machine tool—a 12-inch Craftsman lathe.

An Atlas horizontal mill soon followed, as did a Victor oxy/acetylene torch set. Doug enjoyed the antique engine hobby, and in time had collected several very old Domestic engines. A trip to what would become Coolspring Power Museum, in Western PA, sparked Doug’s interest in large historic engines—which would later become his candidates for scale modeling.

Retirement Leads to a Downscaling in Hobby Size

After Doug retired, he felt that the antique engine hobby was getting a little too heavy, and he began to think about something smaller. Doug attended the North American Model Engineering Society Expo in the mid 90’s and found the perfect solution—scale model engines. His first model engine was a cast fin, air-cooled Domestic, built from a casting kit he bought from Bob Herder at Cabin Fever.

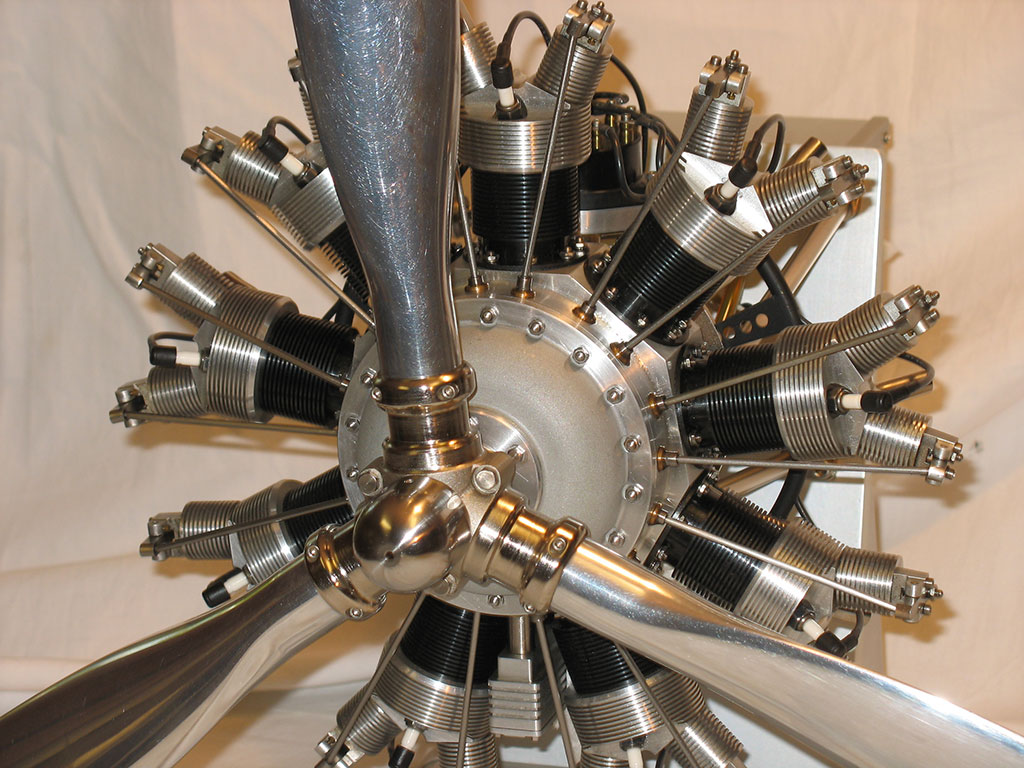

Interestingly, Bob based the model on Domestic engine S/N 624, which Doug had restored for a Domestic engine collector in Philadelphia. From that start, Doug’s model building progressed to more complex engines, like the Hodgson 9-cylinder radial aircraft engine, followed by Bruce Satra’s flat four-cylinder aircraft engine.

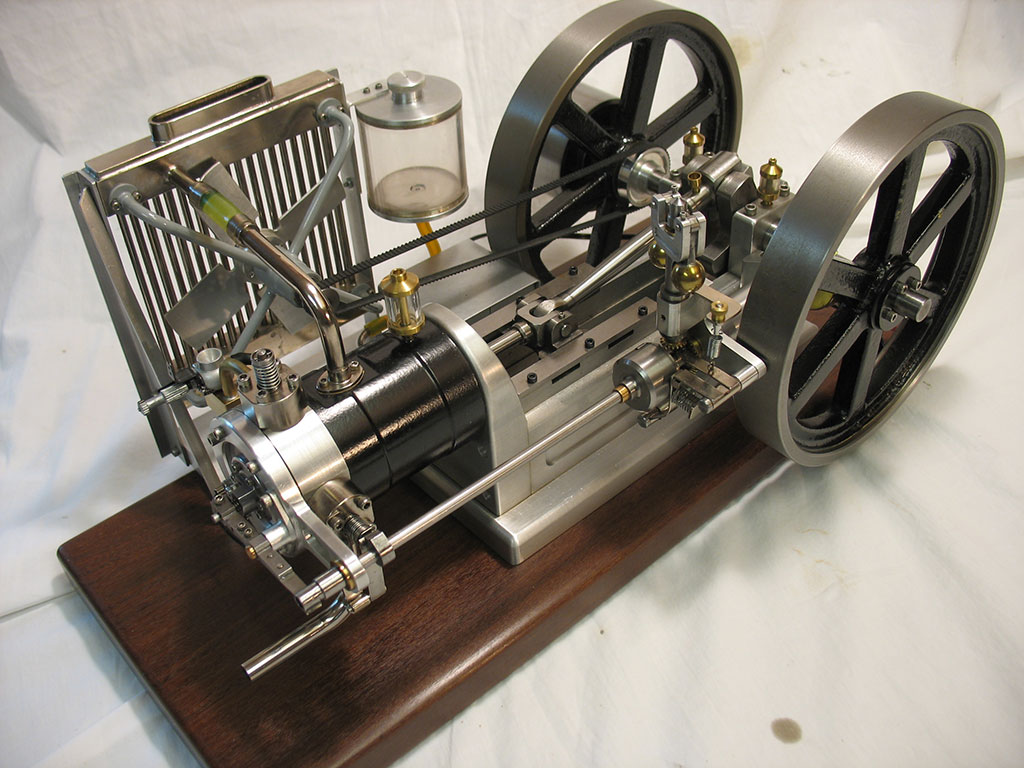

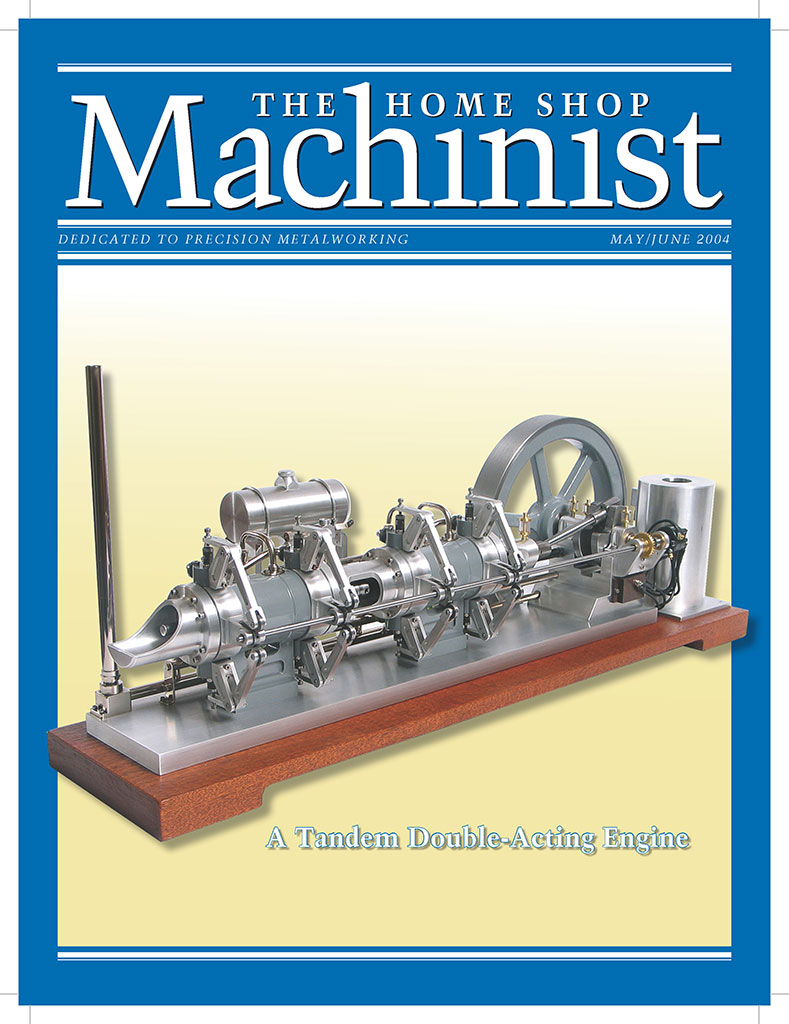

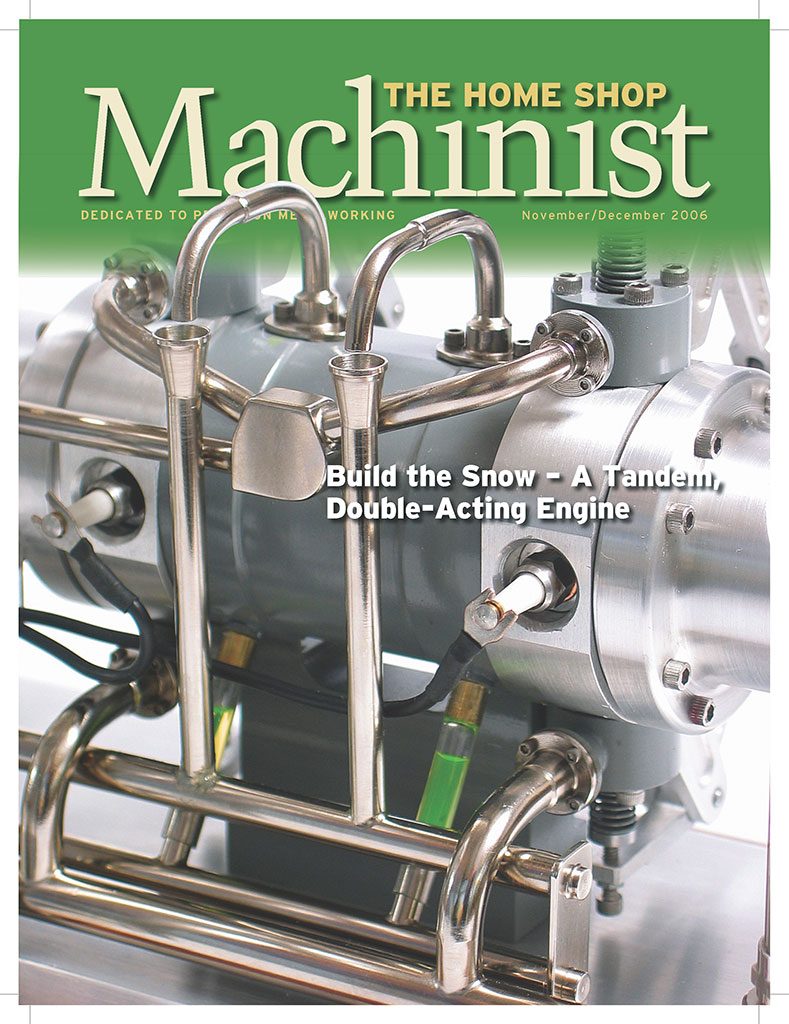

After building engines designed by others, Doug set out to design a few scale engines of his own—he was a design engineer, after all. Doug’s first design was the Snow, a tandem double-acting engine. The May/June 2004 issue of The Home Shop Machinist (HSM) magazine published Doug’s article introducing the Snow engine to the model engineering community.

Next came Doug’s build series for the Snow, beginning with the November/December 2006 issue of HSM. Since then, the Snow has been popular with builders around the world.

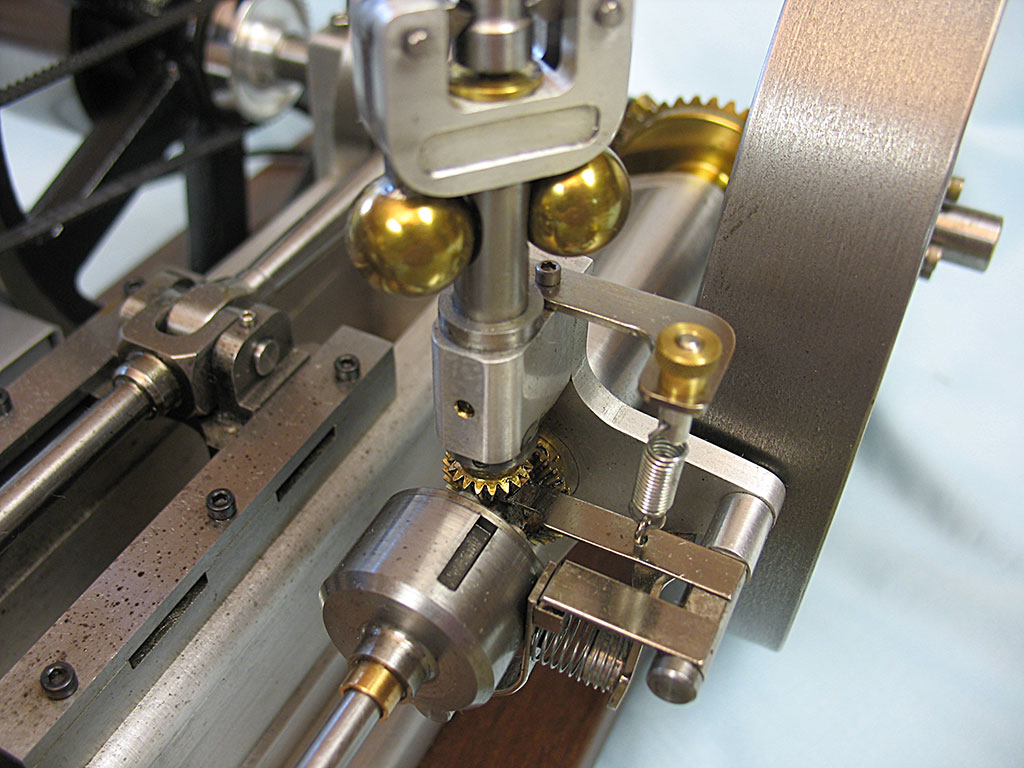

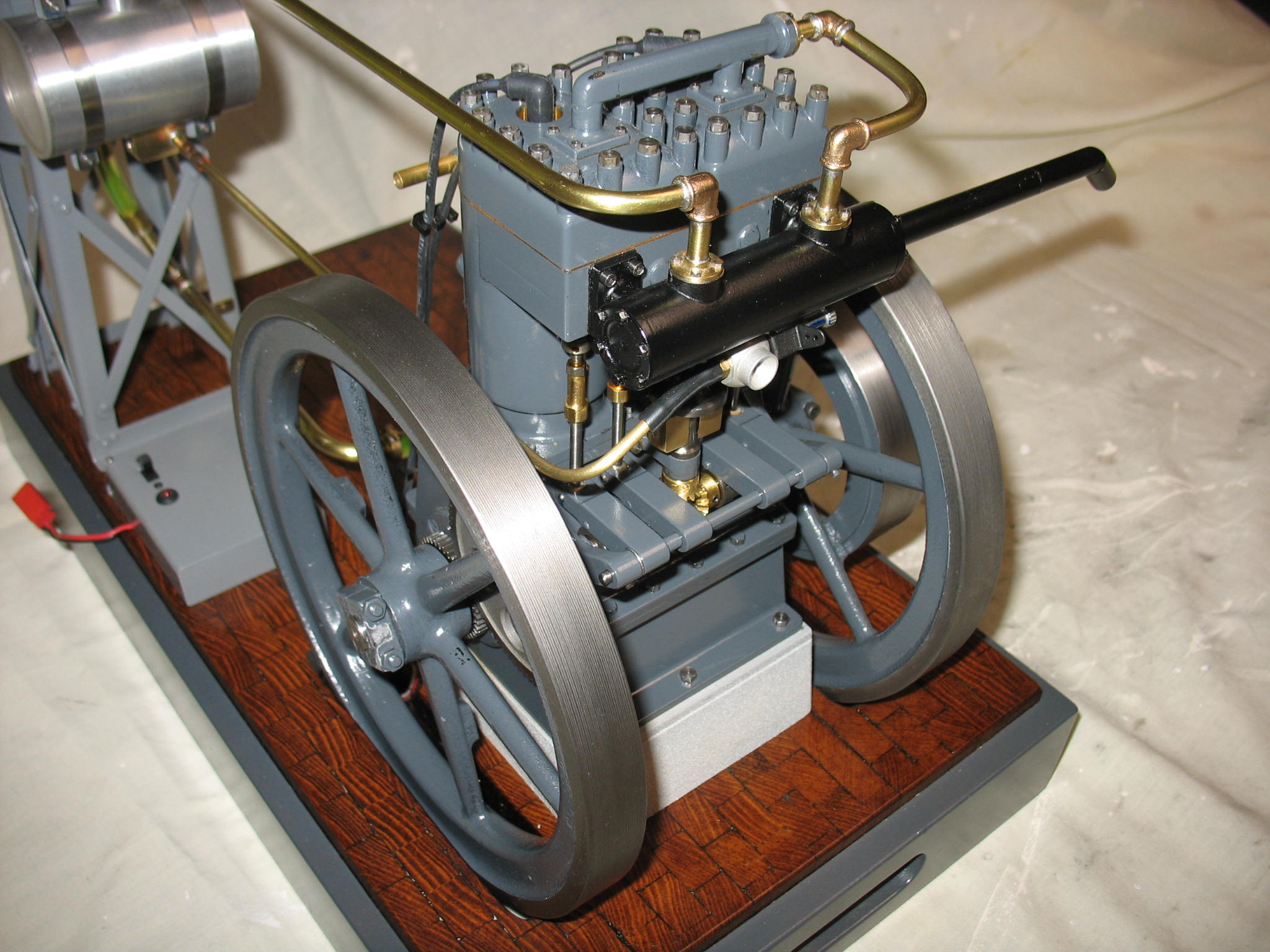

The Snow engine was the first of Doug’s own designs, based on photos and measurements from a full-size engine. With a 1.060″ x 1.880″ bore and stroke, the model is approximately 0.06 scale. The Home Shop Machinist magazine published Doug’s build article for the Snow in four issues, beginning in November/December 2006.

It’s not uncommon to see four or more Snow models on display at NAMES, Cabin Fever, and Paul Debolt’s Zanesville, OH, show. In 2016, Doug’s prototype model of the Snow engine was donated to the Miniature Engineering Craftsmanship Museum in Carlsbad, CA, where it’s now on display. Through his creation of the Snow engine, Doug also met Jeff Connor at Cabin Fever, and the two became good friends.

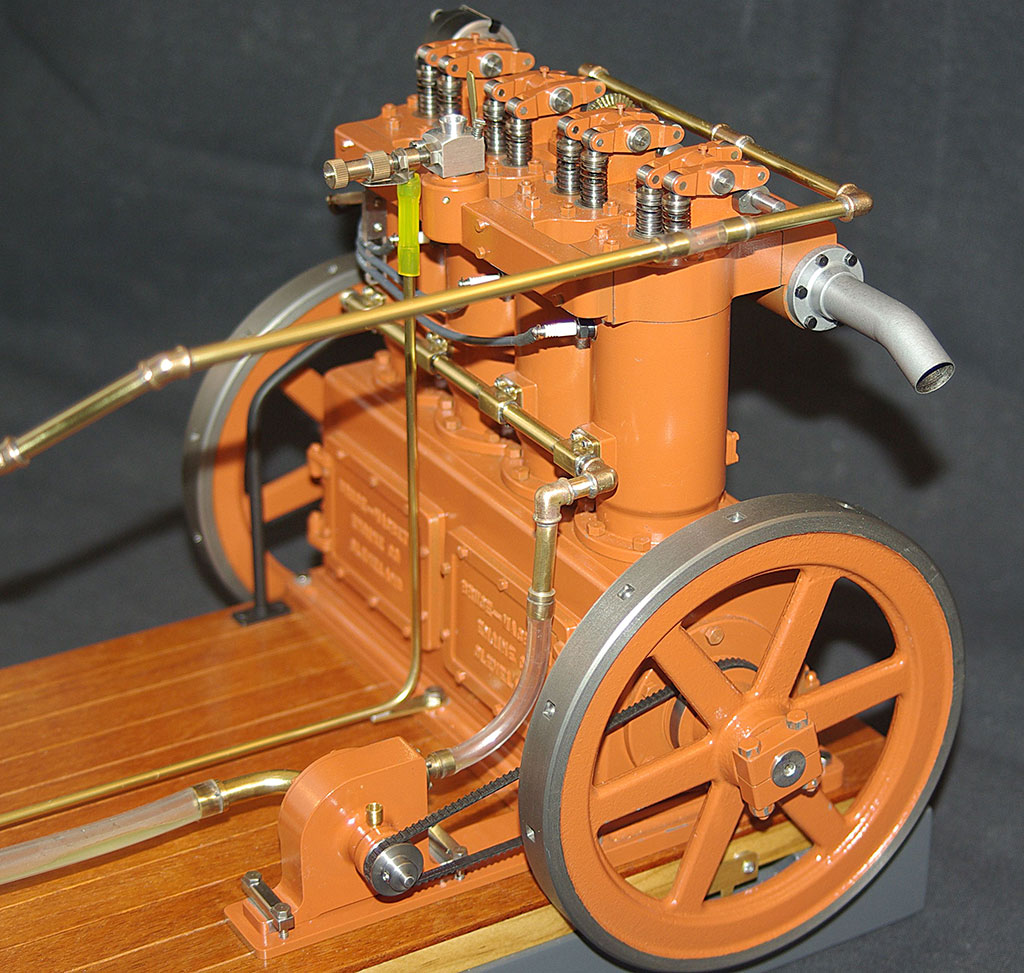

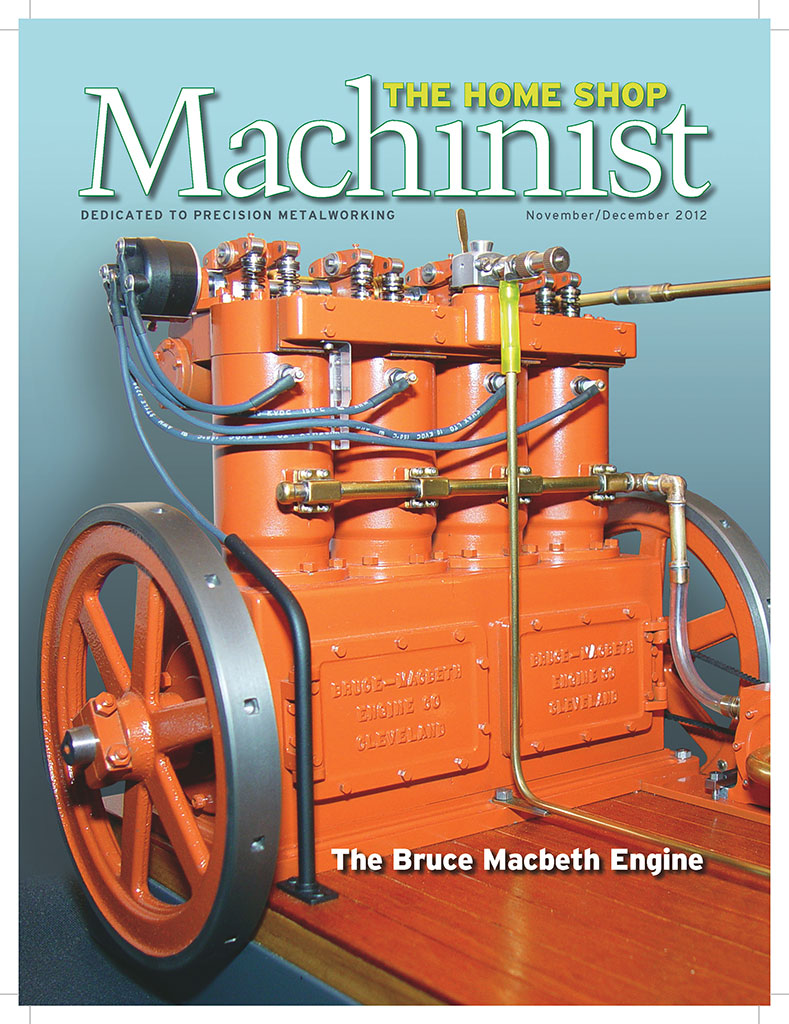

Jeff helped research for future models by taking photos and measurements of existing engines. Using that data, Doug designed his four-cylinder Bruce Macbeth, two-cylinder IHC Titan, two-cylinder Bates & Edmonds, and a two-cylinder Nash. All of the original full-size engines, except the IHC Titan, are restored and running at the Coolspring Power Museum.

The Bruce Macbeth engine has a 1.00” bore, 1.20” stroke, and 5.38” diameter flywheels. Like all of the engines that Doug has designed himself, the Bruce Macbeth was scratch-built from steel and brass stock—except for the cast iron flywheels.

Doug’s Shop

Doug’s shop currently centers around a 10″ x 24″ Rockwell quick-change lathe, and a Clausing Model 8525 vertical mill with a 6″ rotary table. His old Victor oxy/acetylene torch set is still used regularly, as Doug’s engine designs include fabrication of some parts by silver brazing. Additionally, his shop includes a 14″ Rockwell metal cutting bandsaw, Craftsman 10″ drill press, several grinders, and several disc and belt sanders.

In summary, Doug Kelley has built fifteen model internal combustion engines (and counting), including a fire breathing Hurricane gas turbine.

Doug has freely shared much of his design work and construction techniques in the pages of Model Engine Builder magazine, and The Home Shop Machinist, through nine different articles.

Doug’s drawings are also very detailed, using the old school method of pencil and paper. When considering his years building these scale engines, Doug remarked, “The model building hobby has been good to me. So many good friendships have developed. I’m pleased to be associated with so many fine model builders.”

The Hurricane turbine was designed by Neville Robertson of Brisbane, Australia, and published in The Australian Model Builder magazine. On Doug’s turbine, the compressor is a 70 mm wheel from a Volvo turbocharger. The 66.5 mm turbine wheel from Switzerland is cast Inconel 713.

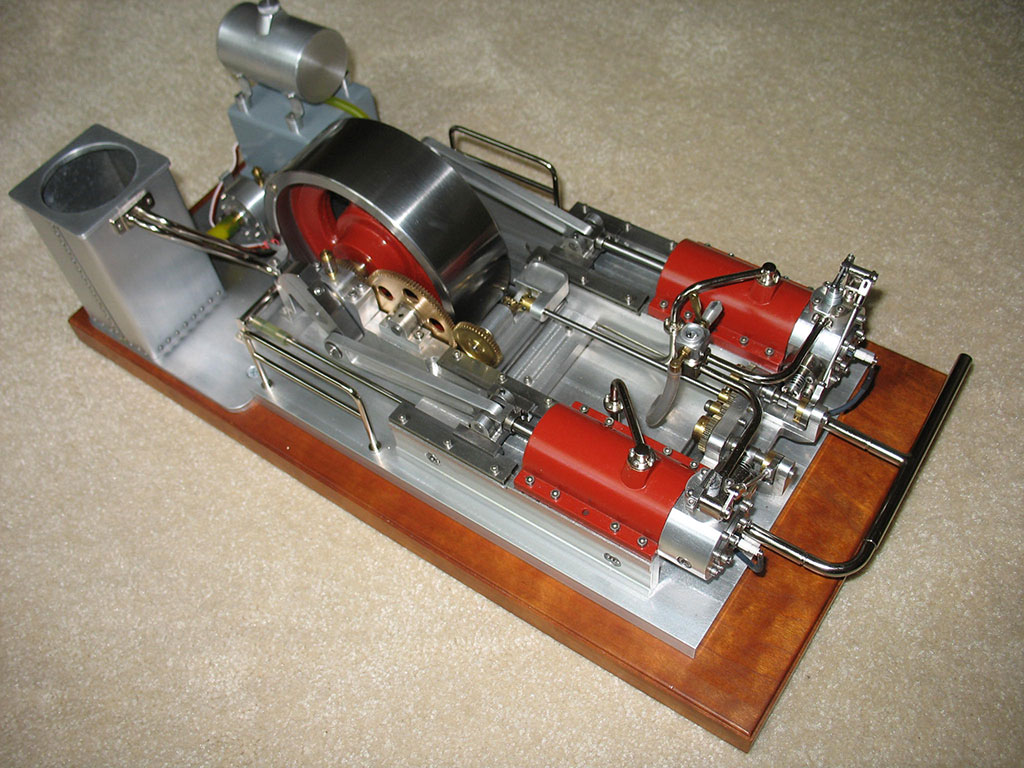

Building a Nash 2-Cylinder Vertical Engine

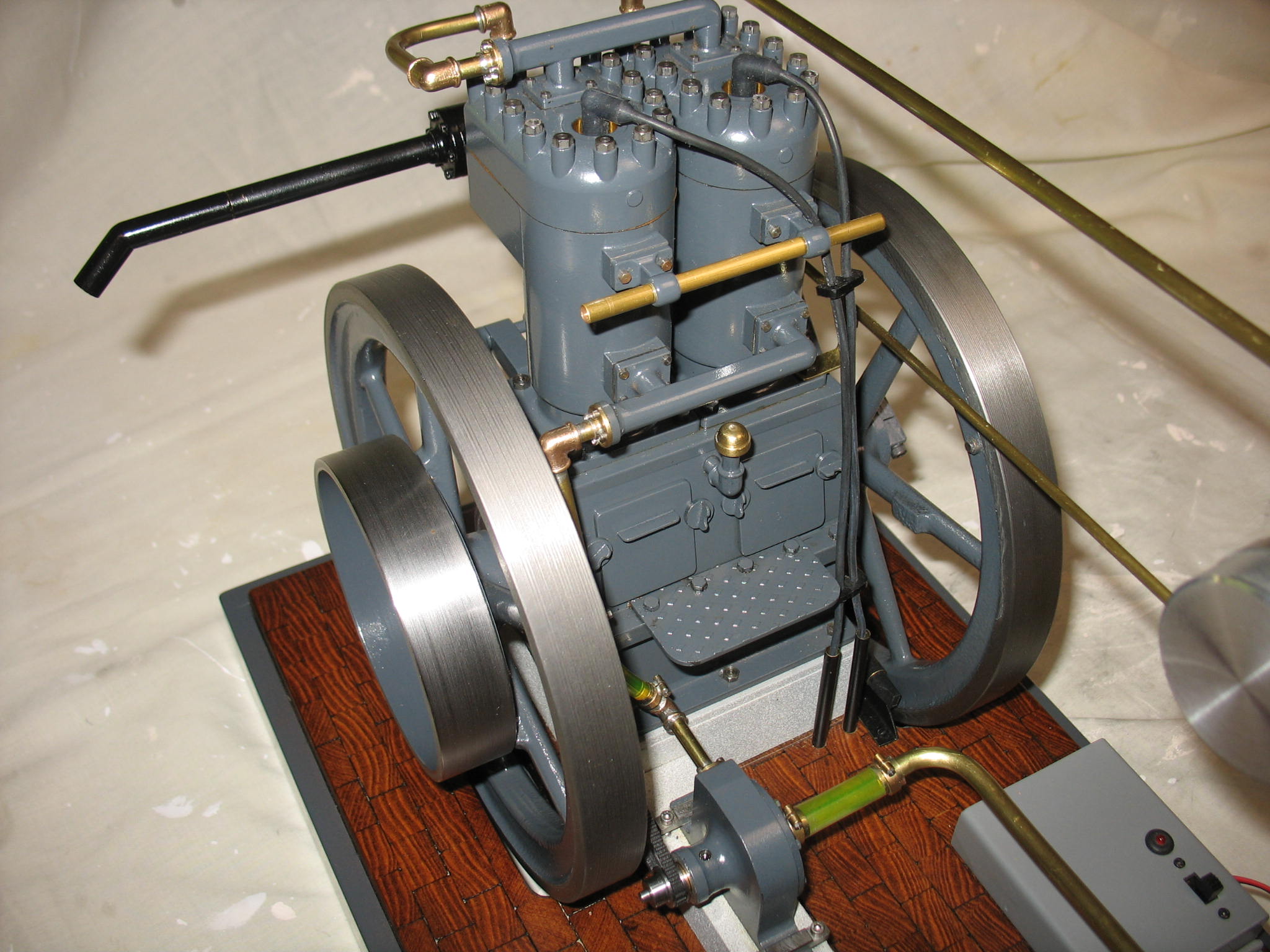

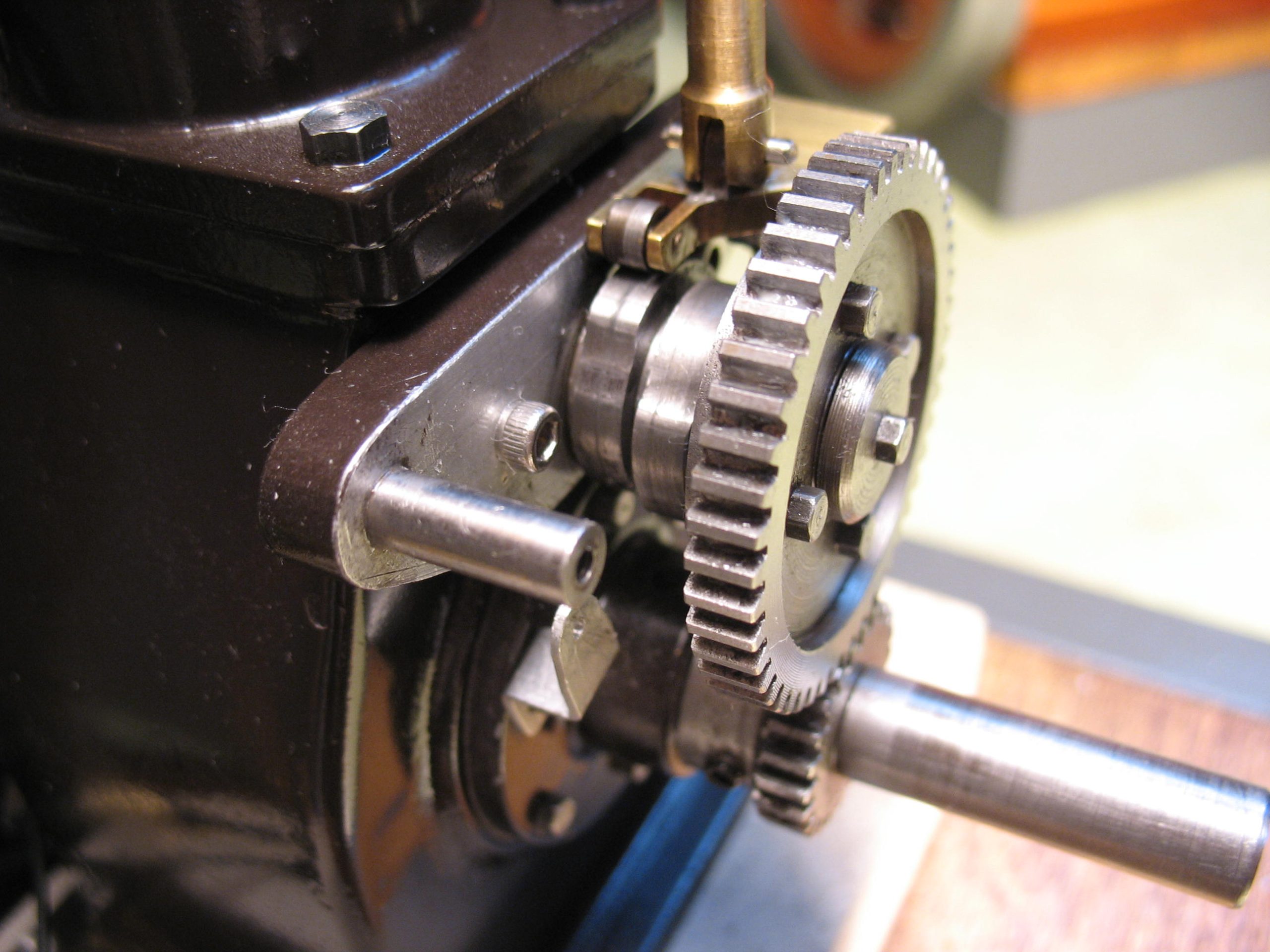

Completed mid-year in 2017, one of Doug’s more recent creations is a 1/8 scale model of a 1906, 25 hp, 2-cylinder Nash engine, built by the National Meter Co. of New York City. Doug’s model is based on the Nash engine at the Coolspring Power Museum. Doug’s model is spark plug fired, with cylinders firing 180 degrees apart, as did the full-size engine. The bore and stroke are 1.00” by 1.31”. Flywheel diameter is 7.50”. With two relatively large flywheels, the little Nash runs slow and smooth. Watch a YouTube video of the Nash engine running.

The Nash is an L-head engine with external camshaft and cam followers on swing arms, as on the original. The cylinder liners, heads, and exhaust manifold are liquid cooled. Fellow model builder, Jeff Conner, contributed to the design by providing photos and measurements from Coolspring’s Nash.

New Engine Update—Building a Merriam-Abbott

In November 2022, we received an update from Chuck Kuhn about Doug’s most recent model, a 1902 Merriam-Abbott engine that was completed in 2021. Mr. Kelley could only find one photo to work from, which was published on page 302 of the book, American Gasoline Engines Since 1872, by C.H. Wendel. The photo shows a single-cylinder vertical engine that was direct connected to a generator. Merriam-Abbott engines were originally manufactured in Cleveland, OH.

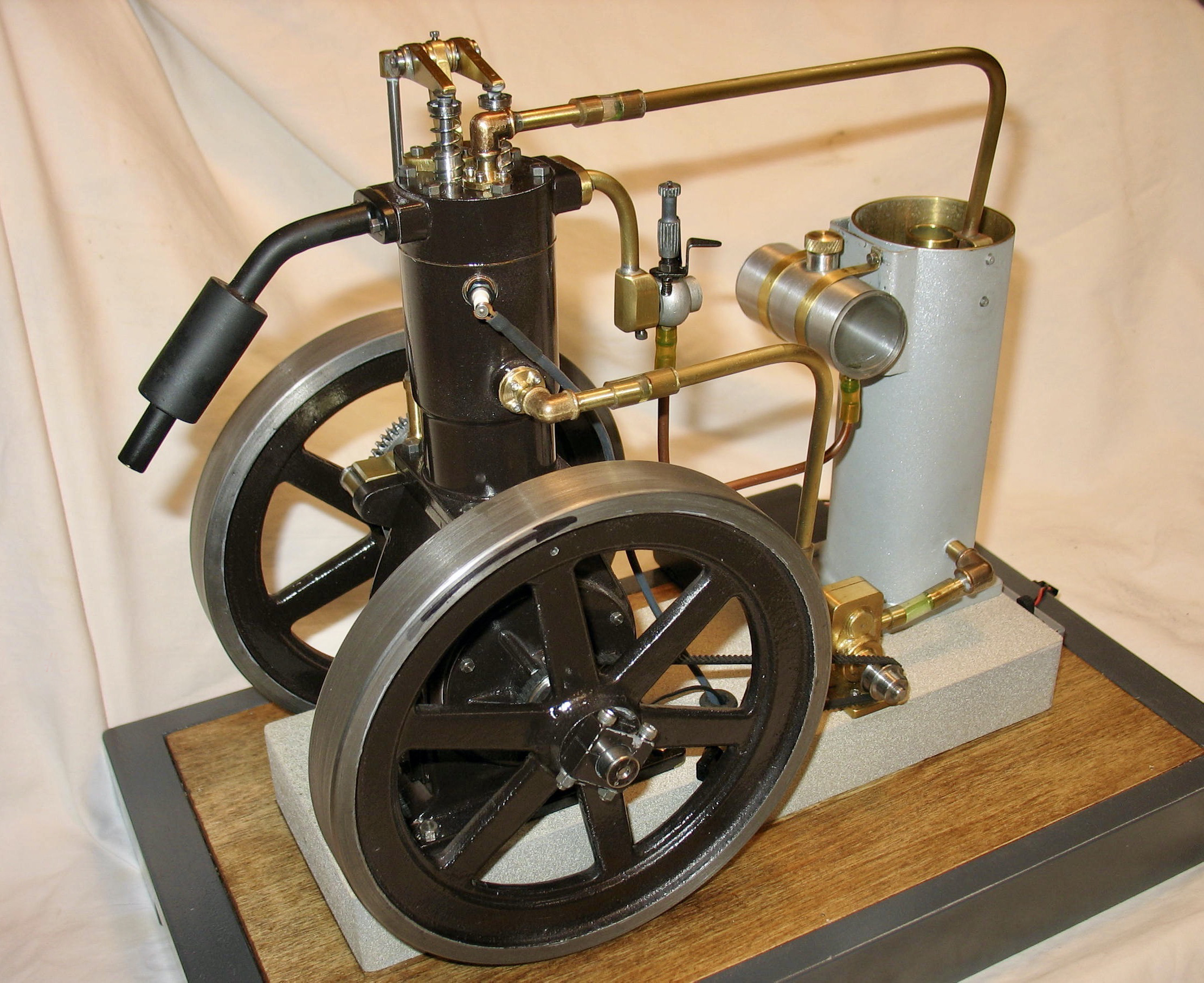

The model engine has a 1.00” bore, 1.25” stroke, 5.5” diameter flywheels, and burns camp fuel with added two cycle oil. Cooling for the cylinder liner and head is done via a cooling tank and small gear pump. The engine is easy to start, runs slow, and has a nice exhaust note.

The Home Shop Machinist magazine is publishing a construction article for Doug’s Merriam-Abbott engine starting in the Nov/Dec 2022 issue. The construction is typical of Doug’s designs, as it starts with brass pieces soldered together to form the crankcase, and builds from there.

We have included some photos of the new engine here. Additionally, you can watch a YouTube video of the engine running, which was posted by Village Press publications.

Early progress on Doug Kelley’s 1902 Merriam-Abbott engine. Doug used a single reference photo for this impressive project. (Photo courtesy of Village Press publications.)

View more photos of Doug Kelley’s scale model engines.