A Skilled and Self-Taught Designer and Builder

Joe Martin Foundation Craftsman of the Year Award Winner for 2020

In most regards, Richard Dosdall is a self-taught designer and builder in both metalworking and woodworking. He is a detail oriented perfectionist in all that he does. In many cases, if he doesn’t have the equipment or knowledge for a task, he builds a machine and/or learns the necessary skills to successfully get the job done. The results depicted in the many examples provided speak for themselves. Some of Richard’s early projects, which were completed before he graduated from high school, include: radio controlled airplanes, clocks, a working steam engine model, and the outfitting of his shop with his first vertical milling machine. In his youth, Richard was instilled with the principle to always do your best no matter the task—a principle that has served him well over the years.

Richard Dosdall’s Story

Below, you will find an autobiography submitted by Richard himself. In it, Richard recounts his early beginnings all the way through to his most recent project (as of 2019). In addition to that, further down you will find a link to Richard’s detailed account of one of his most ambitious projects—a 1/2 scale Oliver 1655 tractor.

Autobiography: Acquiring the Skills to Build a Miniature Tractor, and Just About Anything Else

By Richard Dosdall

I will start back about when I was in 2nd grade, around 1972. My dad, Earl, started selling and repairing the Oliver line of tractors and equipment in 1950, after building a new shop in 1949. When I came along in 1964, my parents had already had three children, and had their parenting skills in place—and they were not to be changed. The guidelines were: After school you get home and get to work in the shop—no sports, etc. The shop was heated with coal using a stoker to feed the boiler.

Dad said, “If the fire goes out, you go out.” In other words, you made darn sure that the stoker was full. When dad would go to town with the truck, and bring home a load of about six tons of coal and back it into the shop, nothing needed to be said. We just grabbed the scoop shovel and started unloading. A full scoop shovel was quite a load for a little guy, but that was how it was to be. What I am trying to say is that all of us kids were brought up in a work-work-work environment.

Building a School Science Fair Project So Well That It Was Stolen

As I grew up a little more, I was always experimenting with things in the shop, learning to solder wires, then how to braze, weld, and use our power hacksaw. (Not a bandsaw, but a hacksaw.) When I was in 7th grade, I built a spectacular electric motor for the science fair. We had to display our projects in the large cafeteria, and the next day, a Saturday, was the judging. When I got there, it was gone. Someone had stolen it. The teachers seemed as if they didn’t care, and nothing was ever found.

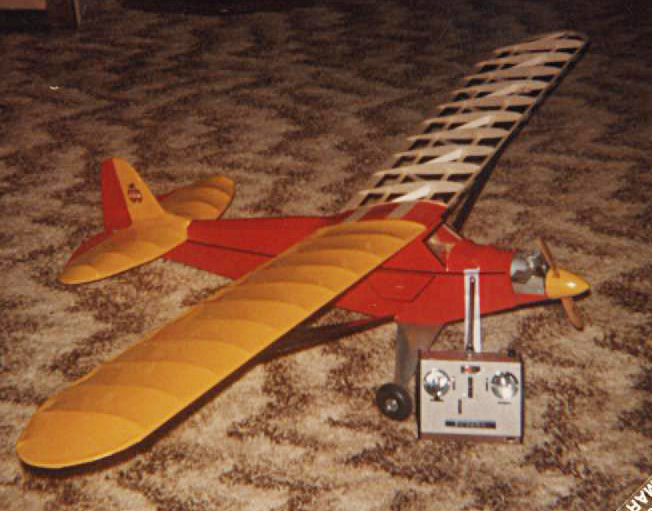

Over the next few weeks, I built another one, even better, just because I could. The science fair was every two years, so by that time I was pretty heavy into radio-controlled airplanes. I entered one that I had left part of the covering skin off of, so that you could see the construction inside. I took 1st place, and went on to the regional competition in a town about 75 miles away, but of course the winner of the regional competition was from that town.

Learning Woodworking and Building Clocks

By 10th grade, I was becoming a pretty good woodworker. My dad had all the basic woodworking machines. Every winter for a while, we would go up in the woods behind the house, cut some logs, haul them to the lumber mill about an hour away, and have them sawed into boards. They would air-dry for at least a year, then we would start building things. I’ve built gun cabinets, china cabinets, roll top desks, coffee tables, end tables, kitchen and bathroom cabinets, just to name a few things.

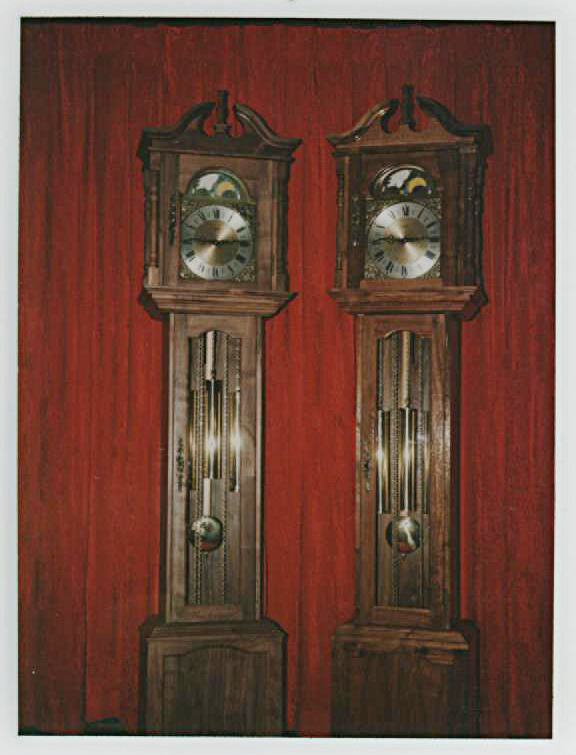

I guess what I liked the most was to build grandfather clocks. In 11th grade, building clocks turned into a business for me. I built and sold many. At this time, I was also using the knowledge that I had learned repairing tractors for restoring antique tractors. I was pretty busy at this time in my life with woodworking, repairing tractors at dad’s shop, and restoring some of my own tractors while I was still in school.

If You Can’t Afford a Full-Size Steam Traction Engine, Build a Scale One

In 12th grade, there was an organization called VICA (Vocational Industrial Clubs of America). I was involved. There was a competition for participants from various schools, for various categories. My category was cabinet making. You would go to a participating school that was putting on the competition. There you would get a set of blueprints for the item you had to build. You would get 10 minutes to look over the prints, and then had one hour to build it. Most of the time the project was not finished in the allotted time. But the judging was done on the precision of the work, the overall craftsmanship, and how far along the completion was. Well, I placed 1st in our local competition, then 1st in the regional, and went on to the national competition in Louisville, Kentucky—where we got to see President Reagan honoring us.

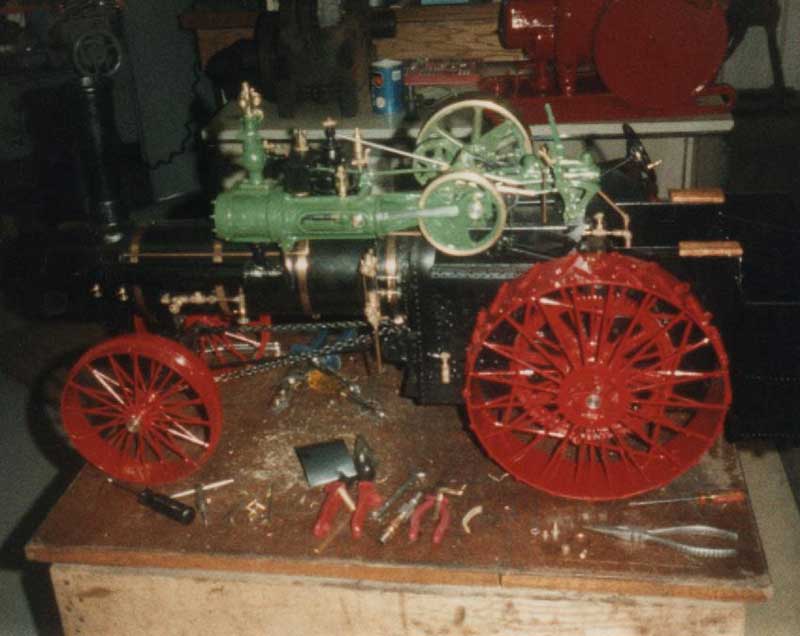

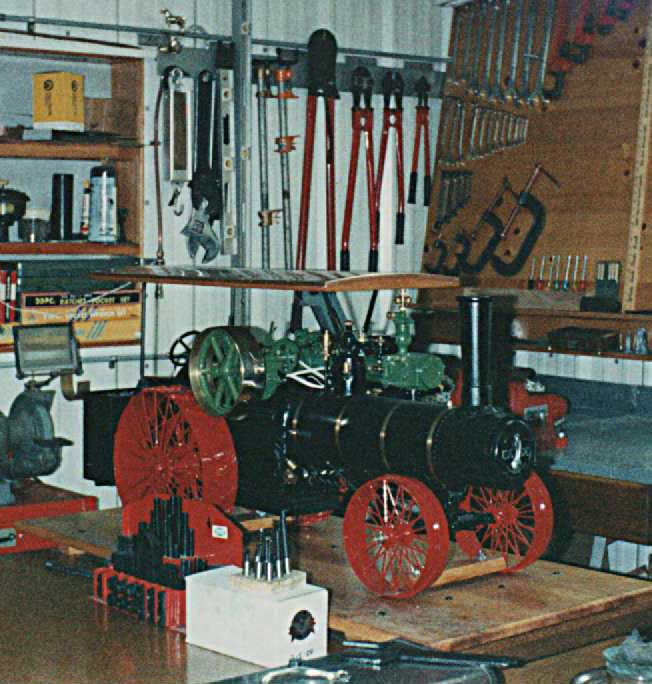

I was also in the metalworking class in school, where we had the basic lathe, one milling machine, and welders. By this time in my life, I had pretty much already learned from my family what the teacher was trying to teach, except for the foundry work. I got interested in that, and did a lot of casting. I was really getting into my old tractors, too. I had it in my mind that I wanted to have a full-size steam traction engine, but when you are only 17 or 18, that kind of money seems way out of reach. I knew the only way that I would get one would be by making one from scratch. Of course, it wouldn’t be full size, but a scale model.

Building the 2” Scale Case Steam Engine

From attending steam threshing shows, I got to know a man who built a 2″ scale Case steam engine. We became good friends. He had made wooden patterns for the castings for his engine. I asked him if I could use his patterns, and he said “sure.” I then asked my shop teacher if I could cast these during class. He agreed. Every day, for many days, I was pouring brass castings for this engine in order to get them all done before I graduated.

Outfitting a Machine Shop

My dad had an Atlas 12″ lathe, but never had a vertical mill. I would need one to build this traction engine. One day after school, I went to a machine tool supply company in Minneapolis to look at a Cincinnati mill that they had for sale. It had a noise in the head, so I didn’t buy it. They wanted $1200 for it. Before I got home, the salesman called, and my dad said that I wasn’t home, but asked if he could help. My dad was kind of stubborn and blunt. They talked about the mill that I had just looked at, and he told the salesman that I said I wouldn’t give him over $600 for it. The salesman accepted it!! So when I got home, my dad told me the story, and that I had bought the mill for $600.

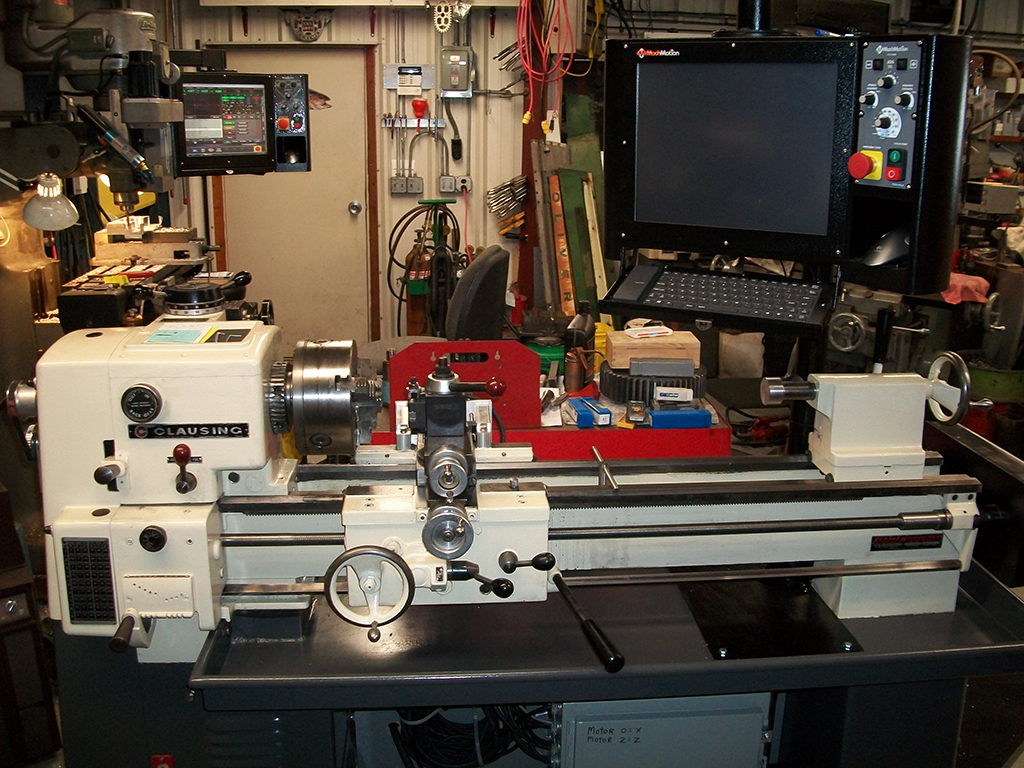

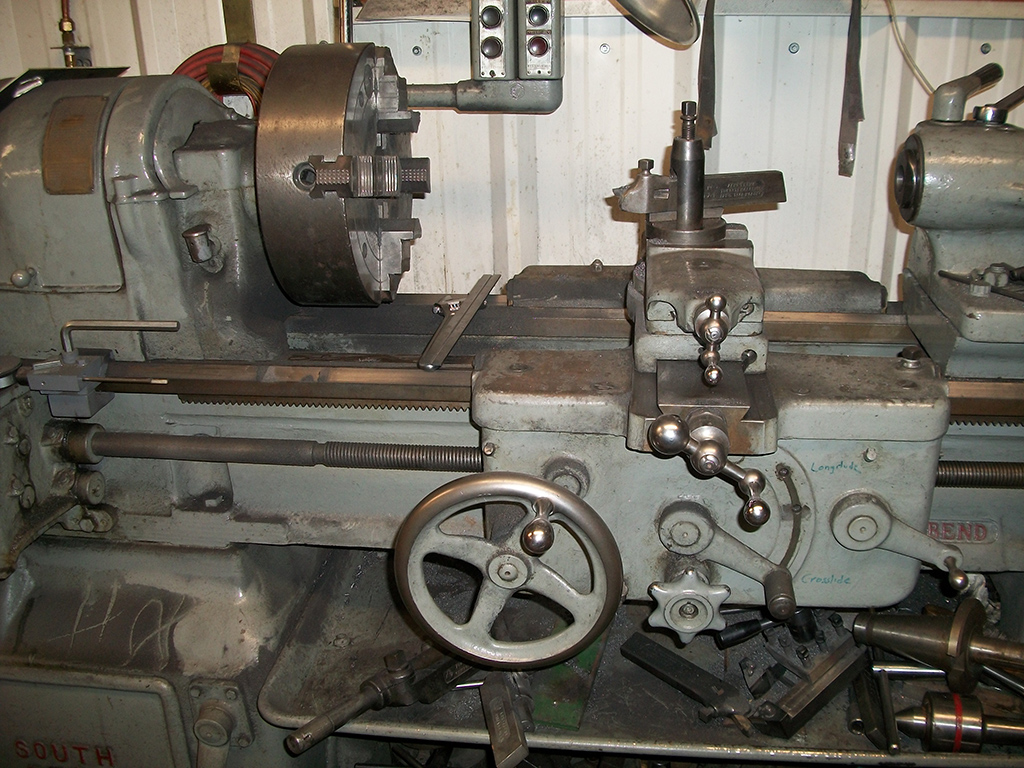

After getting it home and putting it in our newly constructed shop at my parents’ new house (which they had just built), I found that the noise in the head was just the drawbar flopping around since it didn’t have any tool holder in the spindle. Little by little, this new shop turned into my machine shop by adding equipment when I found a good deal. Today, I have: a CNC mill, a CNC lathe (both retrofitted by me), four other lathes, one horizontal mill, another large horizontal mill that I found a vertical head for, a 40-ton shear, a 40-ton hydraulic press, a Fellows gear shaper, welders, and, of course, my first milling machine—the Cincinnati.

After Graduation—Driving Trucks, Working in the Shop, and Restoring Tractors

Okay, backing up a little now. Before graduation, I was selected as the “All Star Industrial Arts Student,” which came with a large traveling trophy that you got to keep for one year. After turning 18, I got my class A driver’s license so I could drive a semi. Soon after, I found a cab-over Peterbilt that I bought to help out with our family business, as the machinery was getting bigger all the time. After graduation, it was working at the shop every day. After work it was working on my antique tractors—which had now turned into antique tractor pulling for me—or working on my 2″ scale Case engine that I had made the castings for.

At one time I had 52 tractors, and sold most of them, but today I’m back to about 30. I did the tractor pulling thing for a couple of years, and have many, many trophies to show for it. A couple of years work and my 2″ Case was completed. At age 22, I ordered a new Chevy pickup. That was my pride and joy. If it looked like rain, I would drive something else. Soon it got so that I didn’t want to drive it at all, because when you are working on greasy farm equipment, your vehicle shows it. Today I still have that pickup, and it has less than 5000 miles on it.

Rich competing in some tractor pulls.

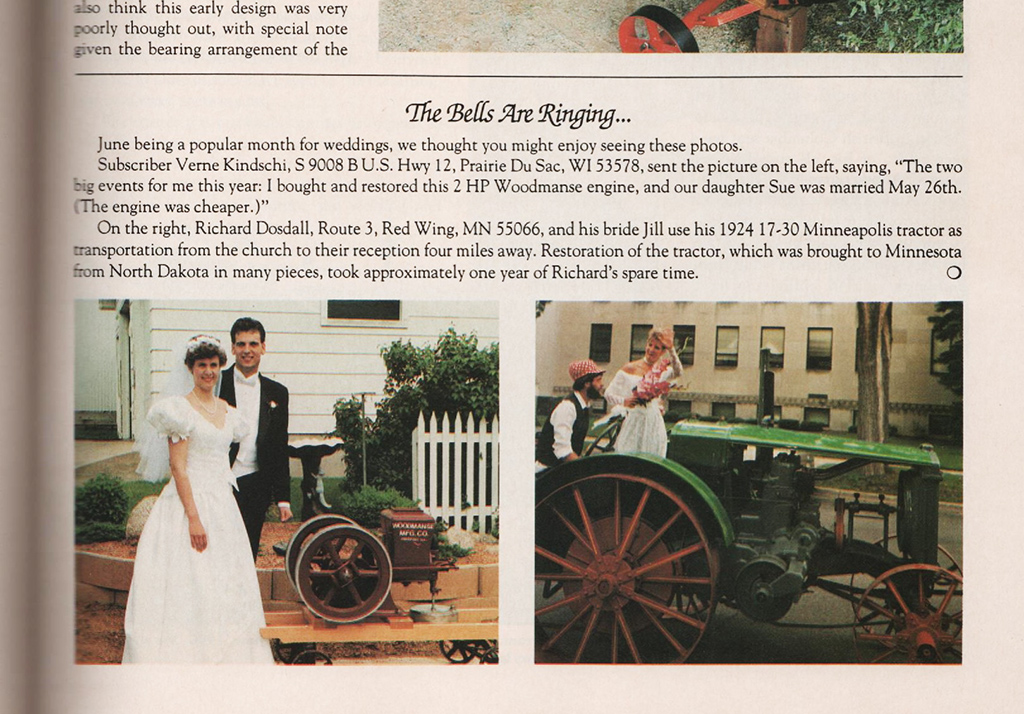

A Shopping Trip With a Friend Nets Several Tractors for Restoration

A friend of mine wanted me to go with him to North and South Dakota to look for some antique tractors to restore. Well, it seems that I bought more than he did. I had most of them sold before I went back to haul them home. One in particular I kept. I shouldn’t say one, because it was two big piles of parts. It was a 17-30 cross-motor Minneapolis tractor. (This was before it became Minneapolis Moline.) For a couple of years prior to this, of course, girls were an interest of mine too. Soon I was engaged.

I wanted to get this 17-30 Minneapolis done and painted, so that my new wife and I could leave the church on it, and drive it to the reception. All went well! Then, a tractor pulling friend contacted me about a 1911 15 HP Case steam engine that was for sale about 1-1/2 hours away. I went and looked at it, and before leaving, a deal was made. Countless hours went into the restoration of that engine, but it is now museum quality.

Building My Own Log Home

Before getting married, I was just telling my bride-to-be that it would be fun to take my semi and find some big trees, and to build a log house. I wanted to do it all by myself. Well, after getting married that is just what I did. I bought three acres of land from my Mother (Dad was now deceased). I borrowed a dozer from a friend, landscaped a building site, and dug a basement—all before the ground froze up for the winter. Our new daughter was six months old the day I started landscaping.

That winter was 1993. I spent that winter peeling logs inside our shop that my brother now owned, and I worked for him instead of my dad. Also, I spent that winter building a sawmill in the shop. It would be capable of sawing a 35-foot log, since that would be how long the floor joist logs would be. I knew of an old sawmill in the woods not far from here that was mostly gone, because of people stealing parts, but enough was left for me to start with. I made it with a hydraulic carriage, and it was driven with the power take-off on a tractor. I put a 48″ blade on it. The next summer I spent sawing all these logs, sawing two sides flat to 8″ thick. This way the logs would stack nicer when building.

Also, that summer I laid all the blocks for the basement, got the finished floor on the main level, and got heat installed in the basement. I then covered it securely for the long winter ahead. A temporary door into the basement through a window allowed me to pretty much finish the basement that winter. During that same winter, I built the four log rafters inside our shop that I would need the following summer. I did get our new house done the next summer. My wife and I did everything ourselves on that house: wiring, plumbing, heating, block laying, and landscaping. We did everything except drilling the well, but we did put the pump in ourselves.

We needed a garage, so the next summer we built a 32′ x 56′ pole shed with two 10′ x 10′ overhead doors. I did this by myself, too. During all of this building, I also had a part time job at the post office as the farm economy took a big hit. (Our daughter now has my old mail route.) This soon turned into a full time job, but I could usually be done by noon or 1:00 PM, then go to the shop for the afternoon, and then work on the house after 5:00 PM. Long days, but I got it done.

Time for a Change of Pace

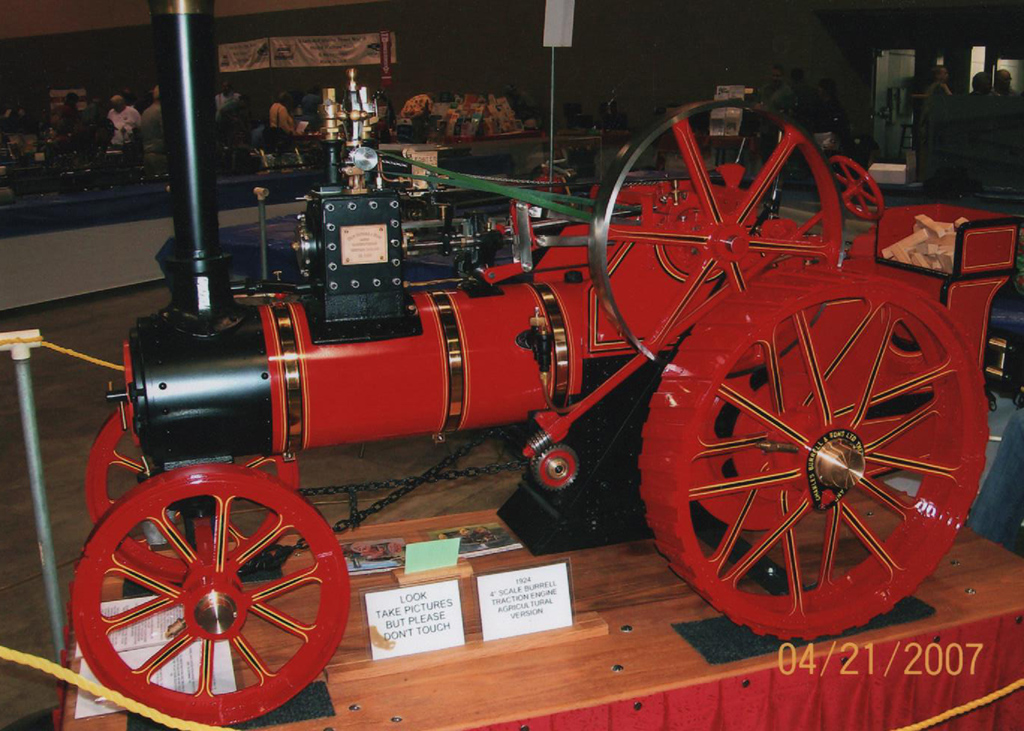

After all of this building, I needed a change of pace, so I got back to my machine shop and started some fun projects. I built a few stationary steam engines, but then I wanted to go bigger. I bought a set of castings for a 4″ scale Burrell steam engine, which is an English engine. I spent the next seven years working on this engine after work and on weekends. The boiler is made of SA 285 grade C boiler plate, and is hydro-tested to 250 PSI.

After finishing this engine, I started building a 4″ scale 65 HP Case steam engine, which I had also bought the castings for. The original patterns for this engine were made by Ralph Endres from Proctor, Minnesota. Since the last boiler I built, they changed the numbering on the boiler plate to SA 516 grade 70, but it’s still the boiler grade material. I spent the next five years on this engine—evenings and weekends.

Two photos of Rich’s finished Burrell steam tractor in 4″ scale.

Back Into Clock Making and Repairing

Around that time, I had been getting a lot of calls from the people that I had built clocks for in the past, wondering if I still worked on clocks. The old ones were beginning to wear out. So I started my own clock repair business, and had more work than I could keep up with. This was also done while I had my post office job, and was still working at the shop. I did this for about 12 years, until my clock part suppliers went out of business, then I quit too. After all of this clock work, and understanding the principles of the clock mechanisms, I thought it would be fun to design and build a clock from scratch.

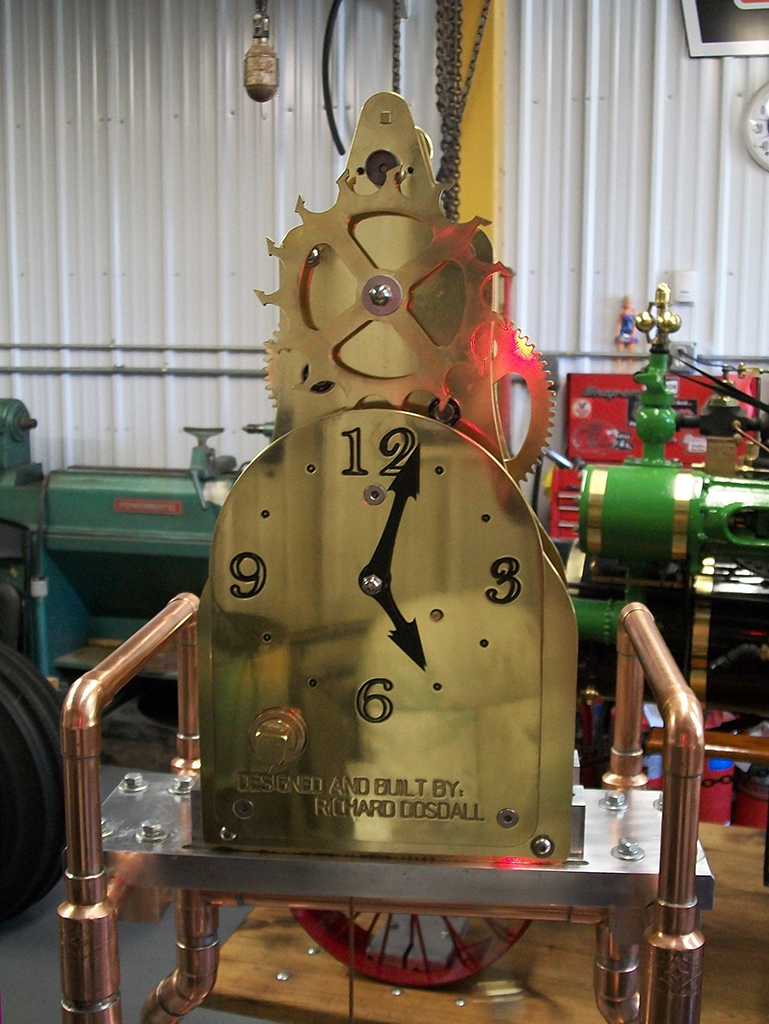

I used 1/4″ brass for the side plates, fitted every shaft with a ball or needle bearing, cut all of the gears myself, and CNC engraved the dial. I copied the escapement from an 1850’s pocket watch, and scaled it up to suit my needs. Then I built a stand out of 1-1/4″ copper pipe, and used a 4″ brass valve as my weight, which can be filled with lead shot to get the proper weight. Next, I built a couple of hit and miss gas engines—a Fuller and Johnson, and a Red Wing—the patterns for which were made by a friend of mine here in Red Wing, Minnesota. However, the patterns are now owned by PM research.

A Recent Project (From 2019)

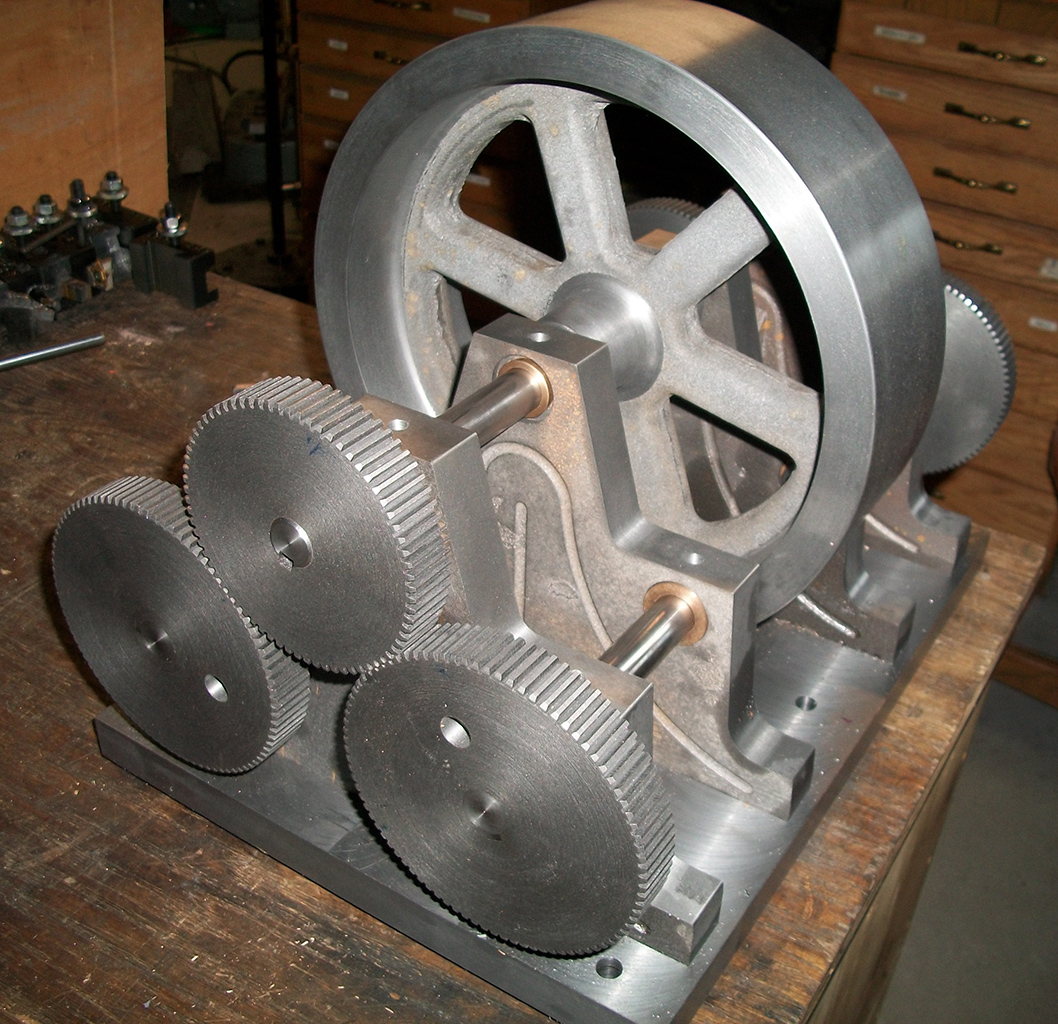

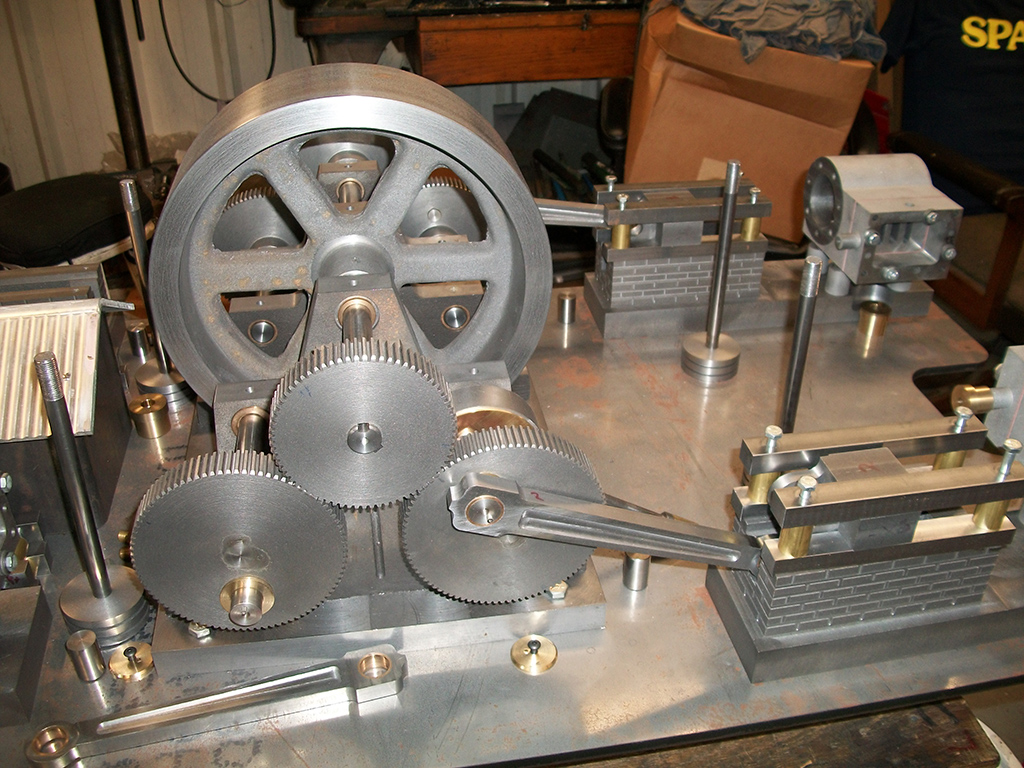

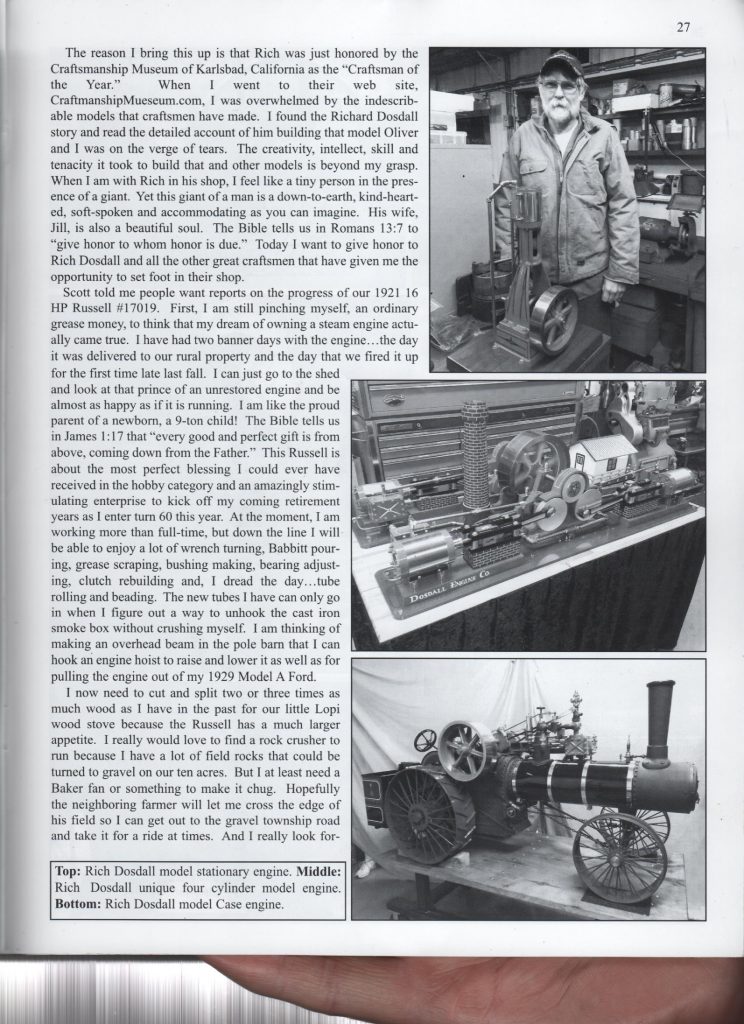

I’m building a 4-cylinder stationary steam engine of my own design. It has a large flywheel in the center, and a cylinder on each corner. The connecting rods are fitted to a gear train that is tied to the flywheel. The pictures show this “work in progress.”

A Lifetime of Collecting Skills and Knowledge

As you can tell, I have done a lot of different things in my life so far, and I like to think that there is not much I couldn’t accomplish if I set my mind to it. I had thought for a long time about building a 1/2 scale tractor, which is 6″ to the foot. It seemed that I couldn’t quit thinking about it, so I had to do it. This would take all of my talents to pull this one off. I remember what these tractors looked like when my dad was hauling them home from the factory to be sold, and my model had to look exactly like they did when they were new.

I am a stickler for detail, and everything had to be correct—right down to where the spot welds are, and how many there are, etc. I know at the beginning I said this was going to be a short story, but I guess I’ve done an awful lot in my life so far, and I didn’t even scratch the surface. From here on you can read a bit more about my projects. Below, you will find the link to read about the 1/2 scale Oliver tractor build—which includes many photos of the process.

Building a 1/2 Scale Oliver 1655 Tractor

Read about Rich’s 1/2 scale Oliver tractor build in great detail, with accompanying photos.

Thoughts on Craftsmanship

I was brought up to do the best quality work on a job. Throughout my life, no matter what the project, I have stuck with that train of thought. My standards have always been very high for my work, and detail is very important to me. Hopefully the younger generation can keep this motto going.

More about Richard Dosdall

You can watch some videos of Richard’s work on his “Dosdall Engine Company” YouTube page. He plans to add more in the future.

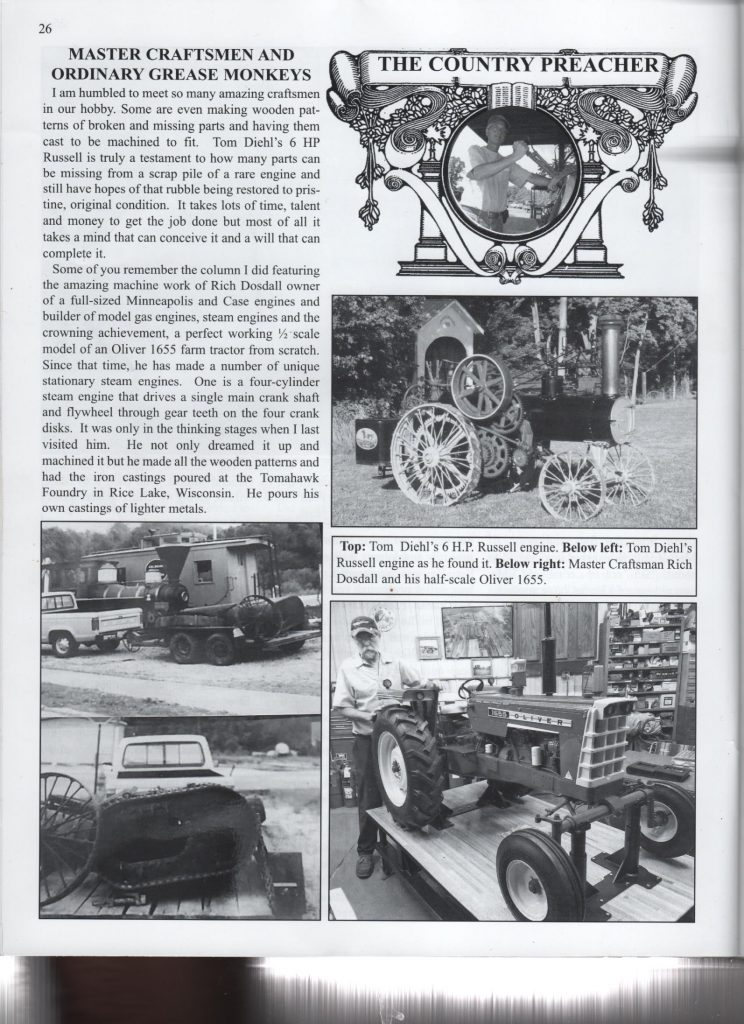

Additionally, you can read an article featuring some of Richard’s work from Iron Age Magazine in the photos below. Click images for full pdf.

Visit Richard’s photo page to see more of his craftsmanship.