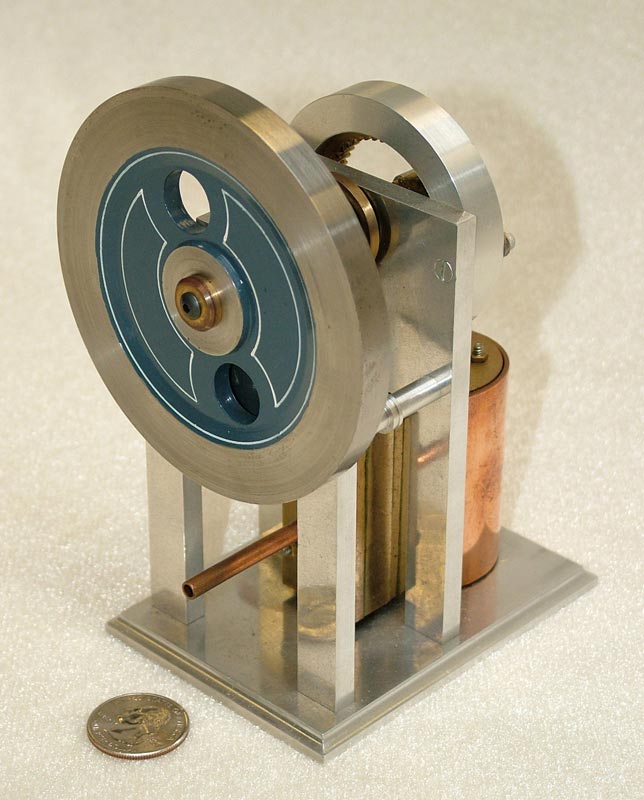

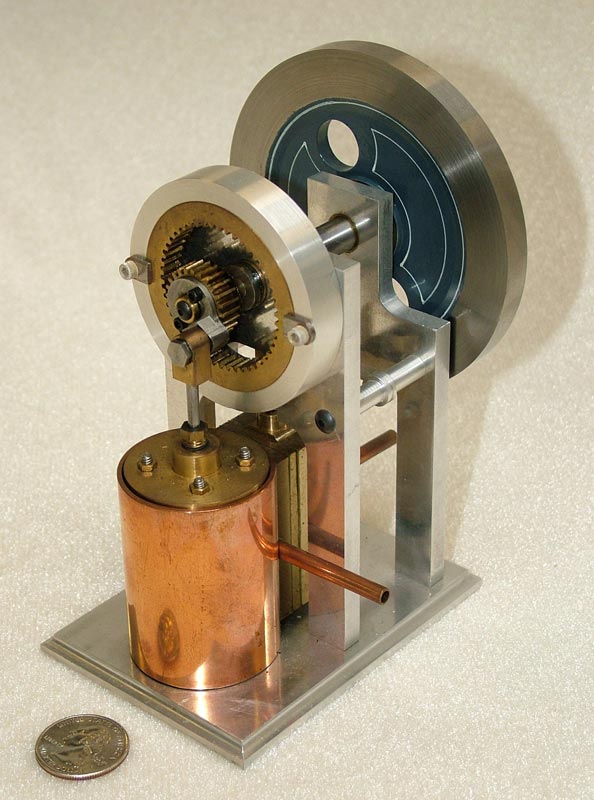

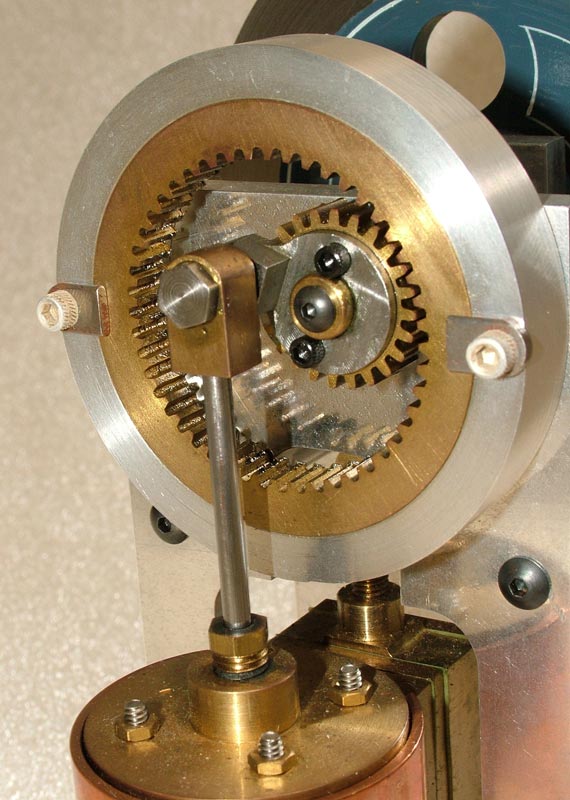

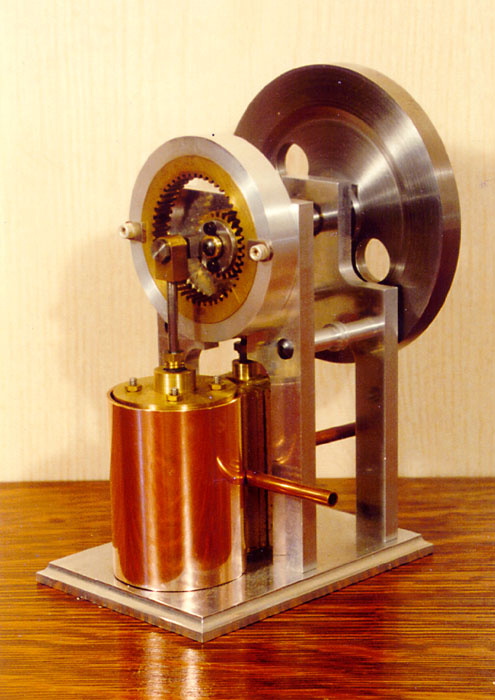

This engine uses a unique mechanism to solve the problem of needing a cylinder to “wobble” or oscillate from side to side to accommodate the piston shaft as it drives the linkage for the flywheel. The engine uses a hypocycloidal planetary gear arrangement to keep the shaft perfectly vertical at all times. The hypocycloidal gears provide a system for guiding the piston rod in a straight line, as the double-acting piston travels through its cylinder. The piston has a 1-1/2“ stroke, and the cylinder has a 3/4“ bore. Rudy fabricated all the parts for the engine from stock materials, including both the internal and external tooth gears–which he cut on his shaper. This engine is set up to run on compressed air in the back area of the Miniature Engineering Craftsmanship Museum.

One of the first large donations to the Miniature Engineering Craftsmanship Museum was the collection of famed model engine builder Rudy Kouhoupt. Rudy’s niece, Susan Alvaro, was kind enough to donate his entire lifetime engine collection for display at the grand opening of the museum in 2006. After retiring as a chemist, Rudy had a second career building engines and writing magazine articles documenting the process. Many people have built his models, but we have the honor of displaying all of his original prototypes. Rudy’s collection includes scale model engines, locomotives, tractors and more. Additionally, thirteen of Rudy’s model steam engines are hooked up to run on compressed air to demonstrate their function.

Watch a video of this engine in action below.