| |

|

The Joe Martin Foundation for

Exceptional Craftsmanship

Presents

The On-line Internet

Craftsmanship Museum

|

| |

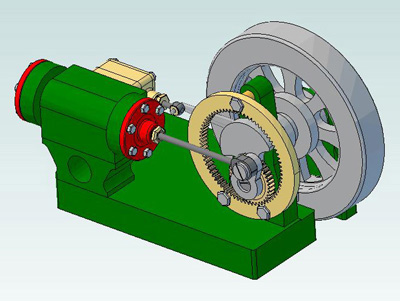

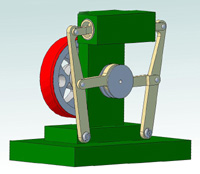

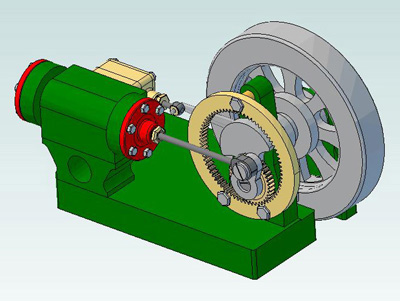

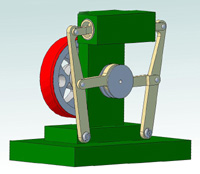

Geared Steam

Engine by Joe Martin (Click on image to enlarge) |

Featuring Alibre Design 3D CAD Design Gallery |

Recent developments in 3D Computer Aided Design (CAD) have brought the price of

programs down to where a home shop user can have access to design tools that

rival that of the professional programs purchased by engineers and big

companies. Programs like Solidworks, Pro/E, Catia, Inventor and SolidEdge cost

many thousands of dollars. However, for the small business or home shop users,

programs like Alibre Design offer all the important features to design

sophisticated parts and assemblies for less than $200. We present here examples

of clever work done entirely in the computer using 3D CAD programs. There are two

categories: 1) Projects re-created in 3D from existing 2D plans and 2) New

projects designed from scratch in the computer.

The old way vs. the new way to design and build parts—Computer

Craftsmanship

The old way was to sketch out an idea on paper and then draw up a set of plans

either on a drawing board or in a 2D CAD program like AutoCAD. Then a prototype

would be built from the plans and parts fitted together. Once the inevitable

mistakes were discovered and design changes were made, eventually you ended up

with a corrected set of plans and an actual working prototype you could look at

from any angle and move the parts to make sure it was what you wanted before

going into production.

That has all changed with 3D design programs. Now the designer can start making

parts right in the computer. He can rotate them around and visualize them from

all angles on the screen. He can color them. He can build up assemblies of

various parts to make sure they fit together. He can then apply constraints to

the various parts so they move in the proper relationship to each other, and he

can animate the whole assembly right on the computer screen. He can also easily

convert the drawing into conventional 2D plans with dimensions, and he can

create cross-sectional views and even exploded views with just a few simple

commands. All of this is before the first part is even made.

Once the assembly is completed in the computer, there are two ways to translate

that into a physical object you can hold in your hand. One is to use modern 3D

printing technology. The drawing is sent to a 3D printer where it goes from a

drawing directly to reality. Various technologies using plaster, plastic and

even metal build a part in thin layers. Molds for the part can also be built in

the printer so the part can be cast. The other method is to translate the

information in the drawing into a text based language called G-code. This is the

language modern CNC machines understand, and they can machine the design from a

solid block of material (anything from foam to metal) to produce the actual

parts exactly like the ones in the drawing. This is the way things are done now

in the industrial world.

For those interested in learning what the Alibre 3D CAD program can do,

CLICK HERE

The 3D CAD Gallery

Industrial Archeology—Recreating

objects and assemblies from existing plans

|

|

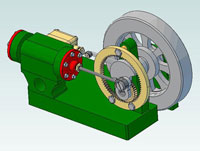

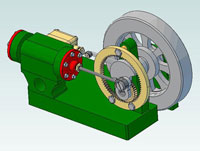

Geared steam engine by Joe Martin.

The

mechanism features a planetary gear the circles inside a ring gear,

keeping the connecting rod level.

Plans: www.John-Tom.com |

|

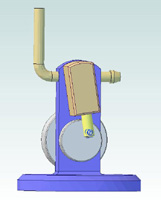

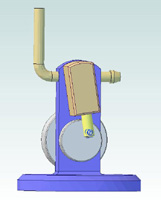

A small oscillating steam engines called "Millie"

by Joe Martin

Plans: From plans reprinted in

Tabletop Machining

by Joe Martin from a design by Ed Warren originally published in

ModelTec magazine |

|

Opposed piston steam engine by Joe Martin

Plans: www.John-Tom.com |

Using the 3D design process to

create new projects

|

|

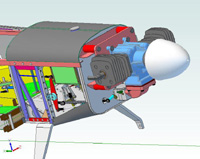

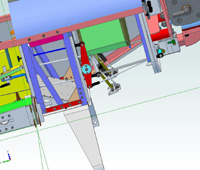

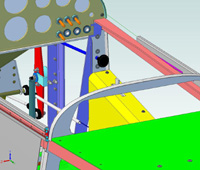

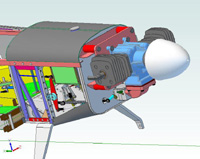

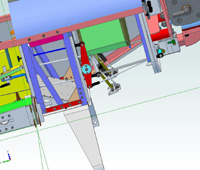

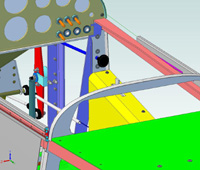

Model R/C Airplane design by Jerry Nelson

Jerry is an R/C flyer, retired hobby shop merchandiser and former

user of SolidEdge 3D CAD software. The plans were taken from a

full-size homebuilt airplane and scaled down to 1/4 size. Like the

real plane, the model will be built using metal panels with

fiberglass cowling, wheel pants and wing and elevator tips. In the

drawing Jerry was able to confirm that fuel tanks will fit, linkages

will clear bulkheads, etc. Working out problems in advance in the

drawing assures perfect part fits the first time when the model is

actually built.

Jerry's design is based on is the

Thatcher CX4, a

VW-powered, single-place sport aircraft that has a wingspan of 24'

and weighs just 520 pounds empty.

NOTE: Jerry Nelson, along with Joe Martin, Bud Crane and Ed Shipe

were the founders of the sport of Formula 1 R/C pylon racing in the

1960's. |

Return to Craftsmanship Museum Home page

Return to Craftsmanship Museum Rooms page